28

SeCTION 4

mAINTeNANCe

Before any maintenance is attempted

on this torch, make sure the POWeR

SWITCh on the power source is in the

OFF position and the PRImARY INPUT

POWeR is DeeNeRGIZeD.

!

WARNING

1. To disassemble the front end, hold the torch with the shield in an upright position.

This will prevent the nozzle, electrode, and swirl baffle from falling free when the

shield is removed.

The gas flow check valve is part of the safety interlock and is permanently as-

sembled in the torch head. The head must be replaced if this valve malfunctions.

The light spring force used to close the ball check can be felt by pushing on the

electrode when assembling the front end components.

2. Periodically check the heat shield, electrode, nozzle, and swirl baffle. Replace if

worn or damaged.

3. Do not continue to use if the electrode end erodes to a length shorter than 16mm

[5/8 in.] as shown in Fugure 4-3 below.

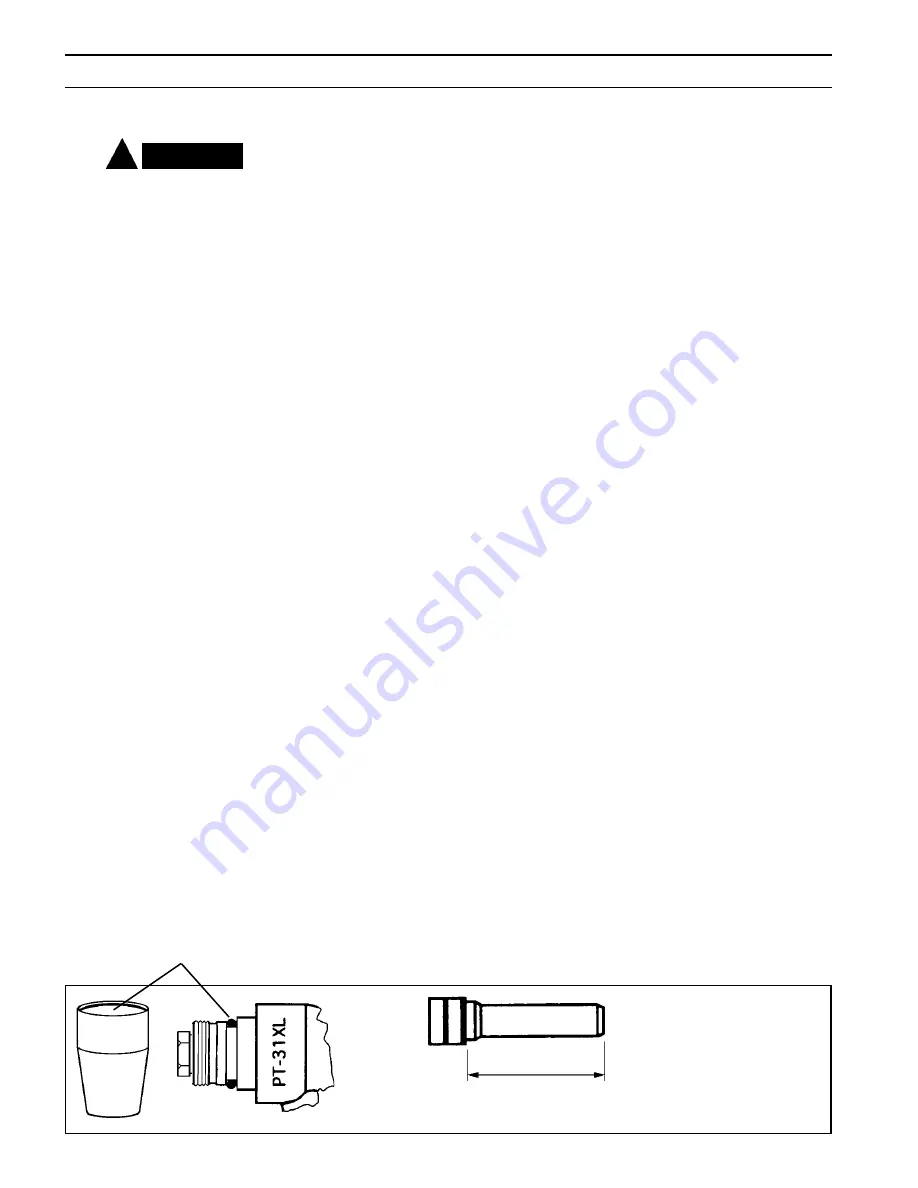

4. Apply a small amount of lubricant P/N 0558000443 (17672), supplied in spare parts

kit, to the heat shield as shown in Figure 4-3 below or to the o-ring. Check o-ring

for damage whenever the shield is removed. Replace if necessary.

Figure 4-3 O-ring and electrode maintenance

16mm (0.63")

Minimum

"XT" Electrode

Replace electrode when end

wears to 16mm (0.63") long.

Lubricant can be applied to

O-ring or Heat Shield

5. The power cable and switch leads in the service line should be inspected periodi-

cally. If there are any cuts through the protective sheath or if gas leaks are noted,

replace the damaged component.

By following Steps 1, 2, and 3 in Subsection 4.5 the service line can be removed from

the torch. To disassemble the service line, lay the line out straight, remove the tape

from around the switch lead splices, and free the switch by cutting the leads close to

the splices. Replacement switches have extra long leads to make up for any loss due

to cutting. Remove the rubber boot from the inlet end of the cable and remove the

tape that secures the sheath at each end. Pull the sheath off the cable (over small

fitting at torch end). Note that the switch leads wrapped around the power cable are

secured with tape several places along the cable. The leads, switch cord plug, and

strain relief can now be removed. DO NOT remove the white tape that forms a band

around the power cable at each end. The sheath is taped to the cable in front of the

band which acts as a shoulder to prevent the sheath from sliding back on the cable.

Replacement cables have this tape in place. If the switch leads are to be replaced,

replace with 16 AWG STRANDED COPPER, 600- VOLT, 90

°

C (194

°

F) INSULATED WIRE.

Reassemble in reverse order.

6. To reposition the switch on the torch, slide the flex support back, remove the tape

securing the spliced leads to the power cable, reposition switch, retape the leads,

and pull the flex support back in place.

NOTE: A thin film of silicone lubricant P/N 0558000443 (17672), supplied with the spare

parts kit, applied inside of the flex support will ease the assembly of this part.

4.4 PT-31xl TORCh mAINTeNANCe

Summary of Contents for 380

Page 4: ... TABLE OF CONTENTS ...

Page 14: ...14 SECTION 1 DESCRIPTION ...

Page 26: ...26 SECTION 3 OPERATION ...

Page 30: ...30 SECTION 4 MAINTENANCE WORK LEAD CONNECTION TORCH CONNECTION ...

Page 41: ...41 Notes ...

Page 42: ...Notes ...

Page 43: ...Revision History Original release 06 2006 03 2007 Revised Title Page layout text ...