29

SeCTION 4

mAINTeNANCe

!

W

ARNING

B

e

SUR

e

to

tigh

ten

fittings

secur

ely

using

2

wr

enches

during

reassembly

.

(F

ac

tor

y

rec

ommended

tor

que

is

30

in-lbs).

F

ailur

e

to

do

so

could

result

in

serious

injur

y

to the oper

at

or

.

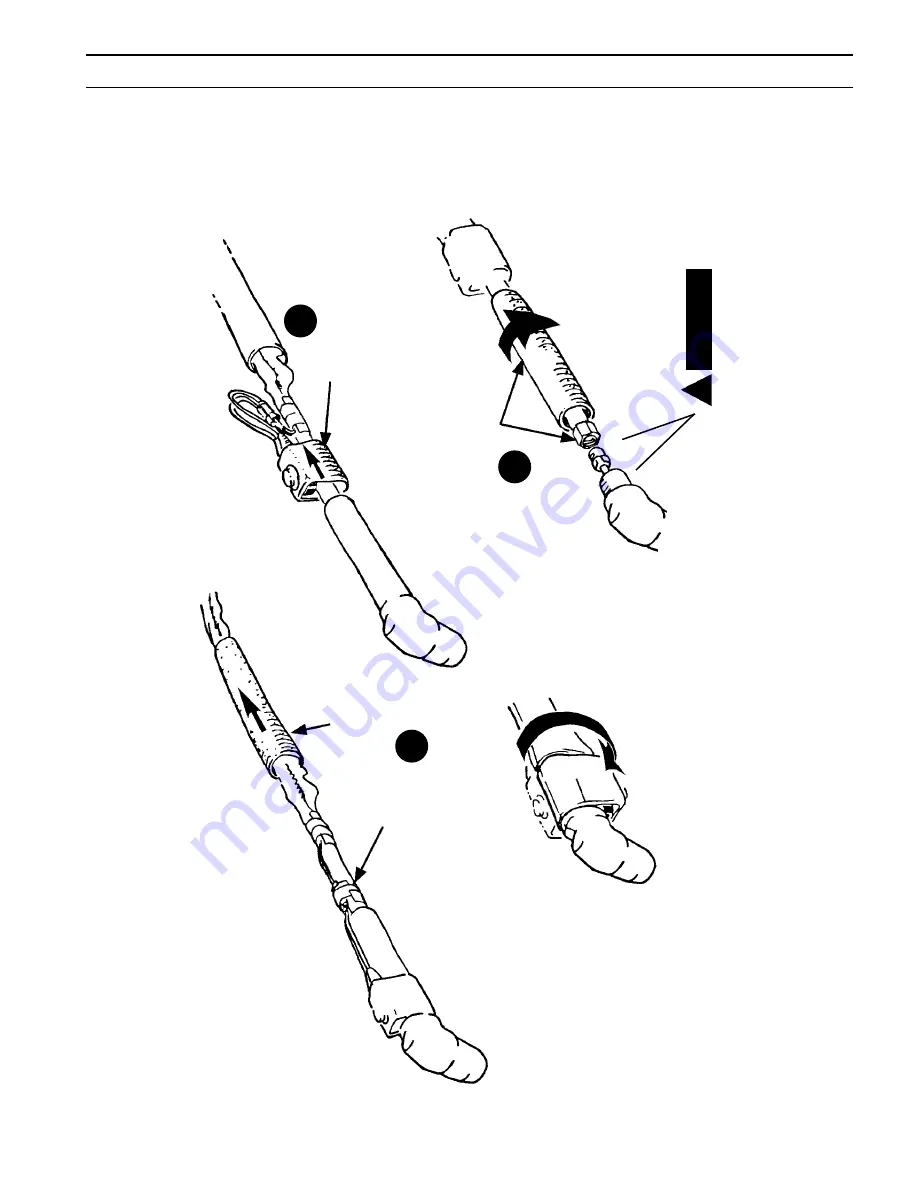

Pull

flex

supp

or

t back.

R

emo

ve

ta

pe

holding

splic

es

.

1

2

3

Slide

swit

ch

a

nd

ba

nd

from

ha

ndle

.

Snip

leads

at

splic

e

to

replac

e

swit

ch.

Unscre

w

ha

ndle

a

nd

p

ow

er

cable

from

head

4.5 POWeR CABle AND SWITCh DISASSemBlY SeQUeNCe

Summary of Contents for 380

Page 4: ... TABLE OF CONTENTS ...

Page 14: ...14 SECTION 1 DESCRIPTION ...

Page 26: ...26 SECTION 3 OPERATION ...

Page 30: ...30 SECTION 4 MAINTENANCE WORK LEAD CONNECTION TORCH CONNECTION ...

Page 41: ...41 Notes ...

Page 42: ...Notes ...

Page 43: ...Revision History Original release 06 2006 03 2007 Revised Title Page layout text ...