22

1. The torch connections are located at the flowswitch

on upper left side of machine.

2. Thread the power cable and switch lead of the PT-

31XL through the right side (above pressure gauge)

bushing of the front panel. Connect power cable to

the torch fitting (left-hand threads) and connect torch

switch leads to pins 1 and 2 of M

2

located in the up-

per right hand corner of machine (viewing from rear

of machine) of the control P.C. Board. Make sure the

power cable connection is wrench-tight.

3. Replace the machine cover panel.

4. Connect your air supply to the inlet connection of

the filter-regulator.

5. Clamp the work cable to the workpiece. Be sure the

workpiece is connected to an approved earth ground

with a properly sized ground cable.

Torch comes factory installed. These instructions are

for torch replacement.

Before making any connections to the power source

output terminals, make sure that all primary input

power to the power source is deenergized (off) at

the main disconnect switch and that the input power

cable is unplugged. for operator safety, the torch

connections are loaded.

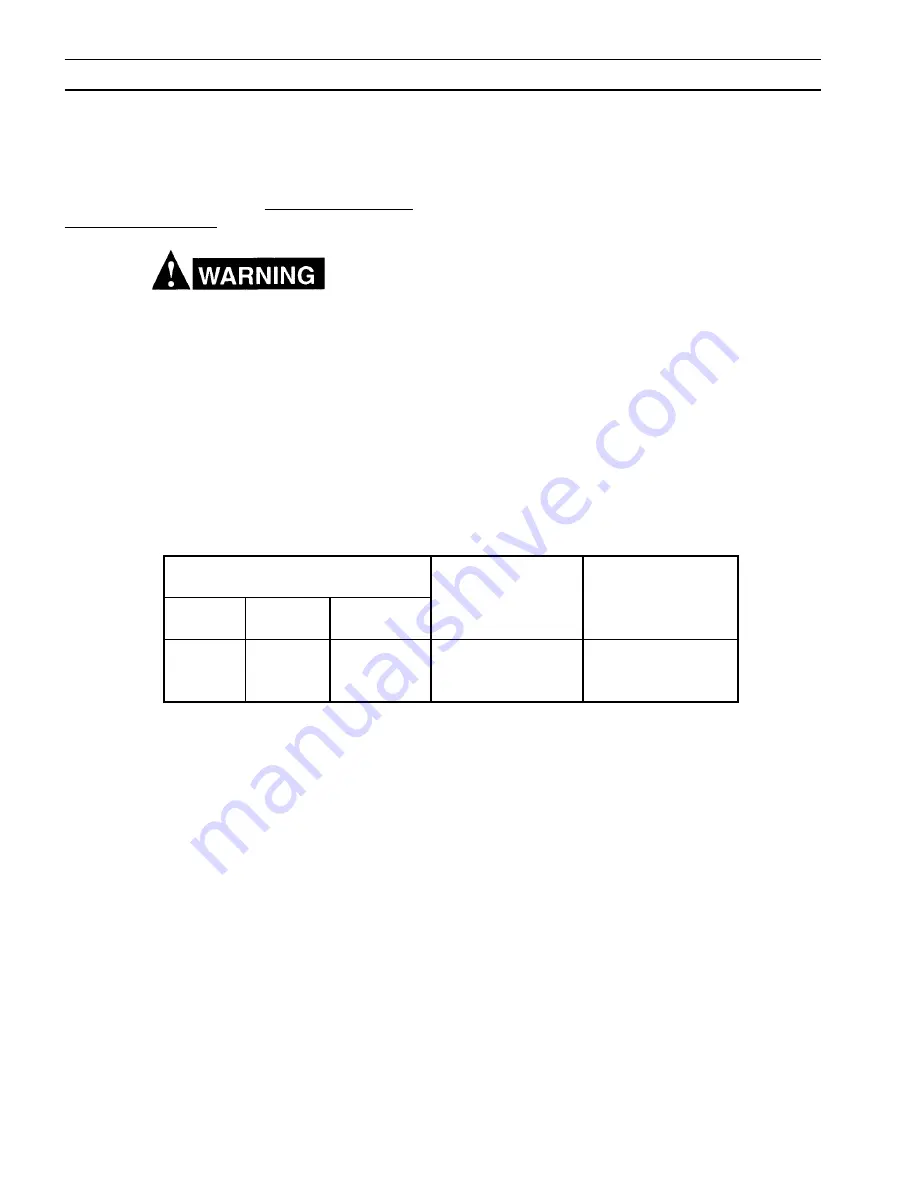

Table 3-1. recommended sizes for Input conductors and line fuses

rated Input

Input & GnD

fuse size

conductor

amps

Volts

amp

phases

cu/aWG*

230

27

1

No. 10

40

*

Sized per National Code for 80°C rated copper conductors @ 30°C ambient. Not more than three conductors in

raceway or cable. Local codes should be followed if they specify sizes other than those listed above.

3.6 seconDary (ouTpuT) connecTIons

(refer To fIG. 3-1)

sectioN 3

iNstallatioN

Summary of Contents for 550

Page 4: ... table of contents ...

Page 20: ...20 section 2 description ...

Page 30: ...30 section 5 maintenance ...

Page 35: ...35 section 6 TROUBLESHOOTING ...

Page 38: ...12 5 4 2 17 14 3 11 7 8 16 10 9 13 6 15 section 7 replacement parts ...

Page 40: ...40 notes ...

Page 41: ...41 notes ...

Page 42: ...notes ...

Page 43: ...Original release 06 2006 03 2007 Revised Title Page layout text revision history ...