70

17.0 Maintenance Procedures

SECTION XVII- MAINTENANCE

PROCEDURES

17.1 Maintenance Procedures

The PRESTIGE Solo should be inspect-

ed and serviced annually, preferably at

the start of the heating season, by a qual-

ified service technician. In addition, the

maintenance and care of the unit as out-

lined on page 69 and further explained

on pages 70 through 75 should be per-

formed to assure maximum efficiency

and reliability of the unit. Failure to ser-

vice and maintain the PRESTIGE Solo

and the system components could result

in equipment failure, causing possible

severe personal injury, death or substan-

tial property damage.

The following information provides

detailed instruction for completing the

maintenance items outline in the mainte-

nance schedule on page 69. In addition

to this maintenance, the PRESTIGE

Solo should be serviced at the beginning

of the heating season by a qualified ser-

vice technician.

17.2 Reported Problems

Any problems reported by the owner should be

checked, verified and corrected before pro-

ceeding with any maintenance procedures.

17.3 Check Surrounding Area

Verify that the area surrounding the PRES-

TIGE Solo is free of combustible / flammable

materials or flammable vapors or liquids.

Remove immediately if found.

Verify that combustion air inlet area is free of

any contaminates. Refer to the materials listed

on page 5 of this manual. If any of these prod-

ucts are in the area from which the unit takes its

combustion air, they must be removed immedi-

ately or the combustion air intake must be relo-

cated to another area.

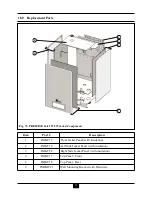

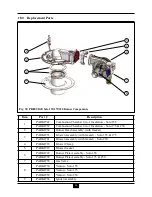

17.4 Inspect Burner Area

Remove the boiler front jacket panel and ven-

turi inlet elbow.

Vacuum any dirt or debris from the

burner/blower components.

Check the burner plate mounting nuts for tightness,

see Section 17.24 on page 75 for torque specification.

Check burner plate gasket for discoloration or

damage.

Re-install venturi inlet elbow and front jacket

panel when completed.

Do not use solvents to clean any of the

burner components. The components

could be damaged, resulting in unreli-

able or unsafe operation.

17.5 Check System Piping

Inspect all piping (water and gas) on the boiler

system for leaks and verify that the piping is

leak free and properly supported.

Inspect the fittings and components on the unit

and verify they are leak free.

Eliminate all boiler water system leaks.

Continual fresh make-up water will

reduce the heat exchanger life causing

boiler failure. Leaking water may also

cause severe property damage to the sur-

rounding area. Inspect the gas supply

piping using the procedure outlined on

Page 60.

NOTICE

WARNING

WARNING

WARNING