74

17.0 Maintenance Procedures

17.18 Check Flame Signal

The flame signal can be read from the Boiler

Information screen. It should be a min. 1

μ Α −

DC

.

Check the ignitor for fouling or damaged

insulation if a low flame signal is read.

Check ground wiring and continuity as a cause

for low flame signal. Replace ignitor if condi-

tions are satisfactory.

17.19 Check Combustion Levels

Refer to page 60 of this manual for measuring

combustion levels and burner adjustments.

17.20 Check Flue Gas Temperature

Manually place the boiler into high fire. See

page 60 for procedure.

Navigate to the Boiler Information Menu to

observe the flue gas temperature. See page 50

for procedure.

If the flue gas temperature is more than 54°F

[30°C] above the supply water temperature, shut

the boiler down and follow the heat exchanger

cleaning procedure below.

17.21 Clean Heat Exchanger

Shut down the boiler:

- Follow the instructions on Page 63 "To

Turn Off Gas to Appliance"

- Do not drain the boiler unless the boil-

er will be subject to freezing condi-

tions.

- Do not drain the boiler if freeze protec-

tion fluid is used in the system.

Allow the boiler to cool down to room temper-

ature before servicing.

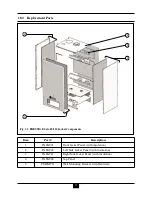

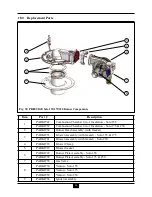

Disconnect the gas piping and gas valve wire

harness connector.

Disconnect the wiring harness connectors from

the blower and remove the blower clamp.

Remove the blower from the unit.

Remove the mounting nuts securing the burner

plate to the heat exchanger and set aside.

Carefully remove the burner plate assembly

from the heat exchanger. Ensure that the com-

bustion chamber 2-in-1 insulation is not dam-

aged during removal of burner mounting plate

assembly. See WARNING on page 75.

Use compressed air or water to remove any

accumulation from the heat exchanger flue

ways.

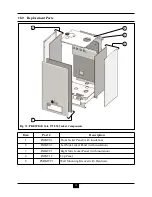

Re-assemble the burner plate assembly onto

the heat exchanger. Ensure the combustion

chamber 2-in-1 insulation is in place, posi-

tioned correctly, and not damaged, replace if

necessary. See WARNING on page 75.

Re-assemble the blower onto the burner plate

and reconnect the wiring harness connectors.

Reconnect the gas piping and wire harness to

gas valve. Check for leaks, repair if necessary.

Torque all screws, bolts, and nuts in accor-

dance with specifications in Section 17.24 on

page 75.

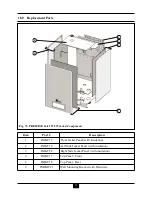

Close isolation valves on the boiler water pip-

ing to isolate the boiler from the heating sys-

tem.

Attach a hose to the boiler drain valve and

flush the boiler thoroughly with fresh water by

using the purge valves to allow water to enter

through the make-up water line to the boiler.

Once the boiler has been completely flushed,

return the boiler and system piping back to

operation.

Perform the required startup and checkout pro-

cedures as outlined on pages 56 to 67.