WT-1550-DM Intelligent Direct Modulated Optical Transmitter

- 15 -

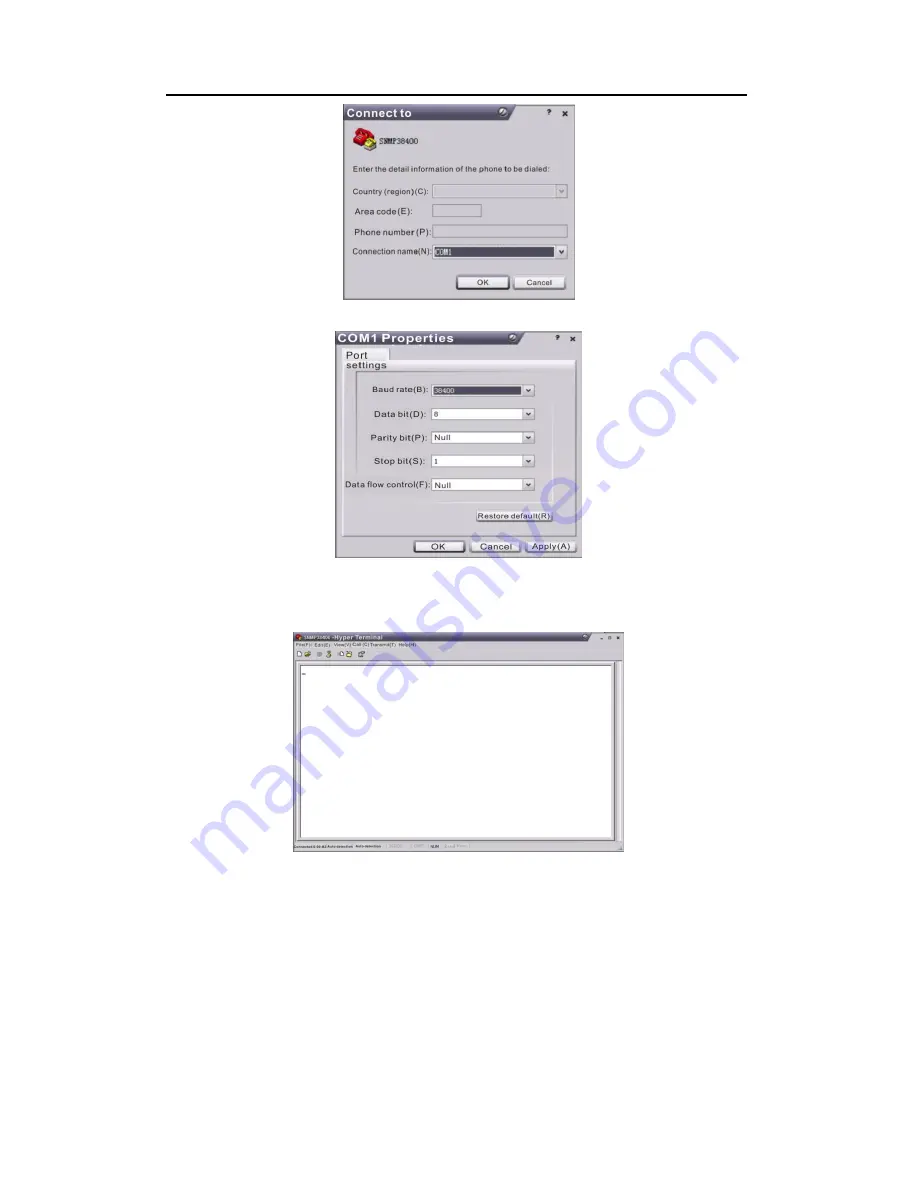

Press the “OK” button shows the configuration page of serial port. As follows:

Change the serial port configuration to 38400-baud rate, 8 data bits, no parity bit, 1

stop bit, no data flow control, press the “OK” button, you have set up the Windows

serial port Hyper Terminal.

You can click “file

save” menu to save this configuration of Hyper Terminal for

later using.