5-50 OTHER FEATURES

PA1628 H3-41, H3-45 Operator’s Manual

2.

Turn power to lift on (LED on TWS module

will light steady) and indicator light on the

control device illuminates. If wheelchair

and passenger are detected by acoustic

sensors the LED will flash, the buzzer will

sound and the module red light will flash.

If this occurs it is necessary to adjust

aiming of sensors.

3.

Turn sensor angle adjustment screw

clockwise to move direction of beam away

from center aisle and towards doorway.

Stop adjustment when LED ceases to

flash.

NOTE

Only in rare instances will adjustment be

needed in the counterclockwise direction.

1.

Move centerline of small wheels of

wheelchair (with passenger) to within 24

inches of doorway and repeat aiming

procedure in previous step.

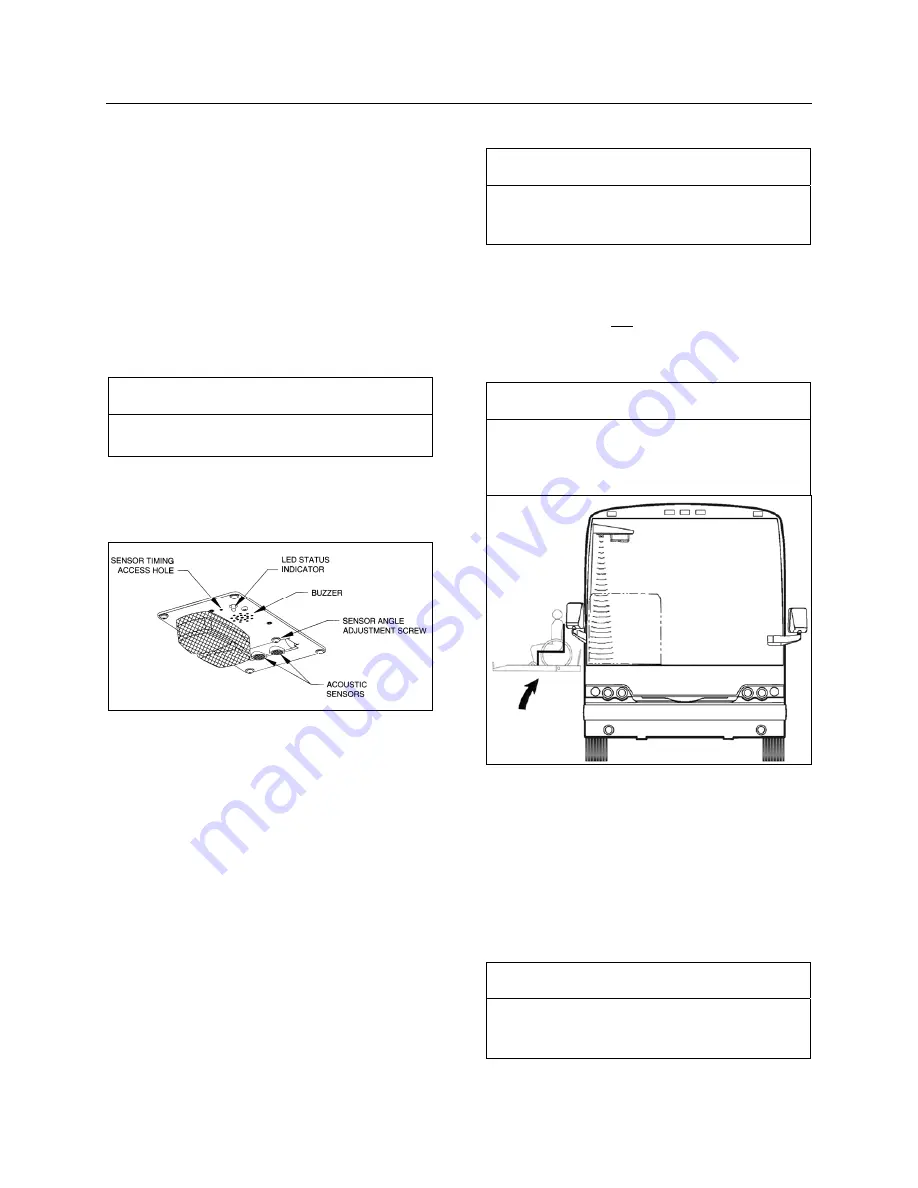

TWS MODULE DETAIL

23368

TEST AIM OF ACOUSTIC SENSOR BEAM

1.

Move wheelchair and passenger slowly

towards doorway. TWS should detect

wheelchair and passenger (LED will flash,

buzzer will sound and the module red

light will flash) when centerline of front

wheels is between 18 and 24 inches from

doorway.

2.

Open vehicle access door above lift. Lower

platform to ground and place wheelchair

and passenger at rear of platform.

Rollstop (rear barrier) should be up. Raise

platform to floor level. This normal

platform motion with wheelchair and

passenger aboard should not actuate

TWS. If LED does flash (buzzer will also

sound and module red light will flash),

turn sensor adjustment screw slightly

counterclockwise.

NOTE

If an adjustment is made, repeat the previous

step where wheelchair is between 18 and 24

inches from doorway.

ADJUST ACOUSTIC SENSOR TIMING

1.

Support a flat sheet of cardboard, or

similar material, directly beneath TWS

module at a distance of 4½ feet below

module. Sheet must be facing sensors.

NOTE

Before proceeding, visually inspect sensors to

verify that they are pointing directly at floor,

or nearly, and are not pointing off at an

extreme angle.

CHECKING NORMAL PLATFORM POSITION

23372

2.

Note the sensor timing access hole. This

hole provides access to a plunger-

actuated switch that sets the sensor

timing. Insert a 1/16-inch diameter wire-

like object into the access hole and press

the plunger inward. The LED will flash

momentarily while the module

establishes the distance and then remain

on steady. Release the plunger when the

LED ceases to flash.

NOTE

It is important that objects, such as your

body, tools, seats, etc, do not interfere with

the beam while the adjustment is being made.

Summary of Contents for H 2018 Series

Page 1: ...COACH MANUFACTURER OPERATOR S MANUAL H SERIES COACHES PA1628 January 2018 ...

Page 8: ......

Page 10: ......

Page 14: ......

Page 30: ......

Page 114: ......

Page 217: ...TECHNICAL INFORMATION 9 5 PA1628 H3 41 H3 45 Operator s Manual H3 45 OVERALL DIMENSIONS 18525 ...

Page 232: ......

Page 236: ......

Page 256: ......