7-8 SAFETY FEATURES AND EQUIPMENT

PA1628 H3-41, H3-45 Operator’s Manual

TIRE PRESSURE MONITORING SYSTEM (TPMS)

(OPTIONAL)

The coach may be equipped with the optional

Tire Pressure Monitoring System (TPMS).

Description

System includes the following elements:

Special tire valves;

RF sensor inside each tire, fixed to the valve;

3 antennas to receive the sensors RF signal

(one in the front spare tire compartment, one

above the L.H. side rear wheels and one

above the R.H. side rear wheels);

A TPMS receiver connected to the antennas

and located in the front electrical

compartment, above the CECM;

A TPMS display built in the L.H. dashboard

panel;

A “FLAT TIRE” telltale panel indicator.

The section of the special tire valves located

inside the tire is dome-shaped to allow fixing the

sensor.

Sensors provide continuous tire pressure and

temperature reading.

The normal sensor battery lifespan is 5 years.

The remaining lifespan is displayed as a

percentage in the TPMS display.

NOTE

It is recommended to check the remaining

battery lifespan when changing the tires in

order to replace the sensors at the same time

if they are due for replacement before the

next change.

The screw fixing the sensor to the valve can only

be used once because the threads are powder-

coated to lock the sensor in place and prevent

unfastening.

The telltale panel indicator illuminates for 3

seconds when the ignition switch is turned ON

to check the display operation and the

communication between the display and the

vehicle multiplex system. This confirms the

communication between the TPMS display and

CECM.

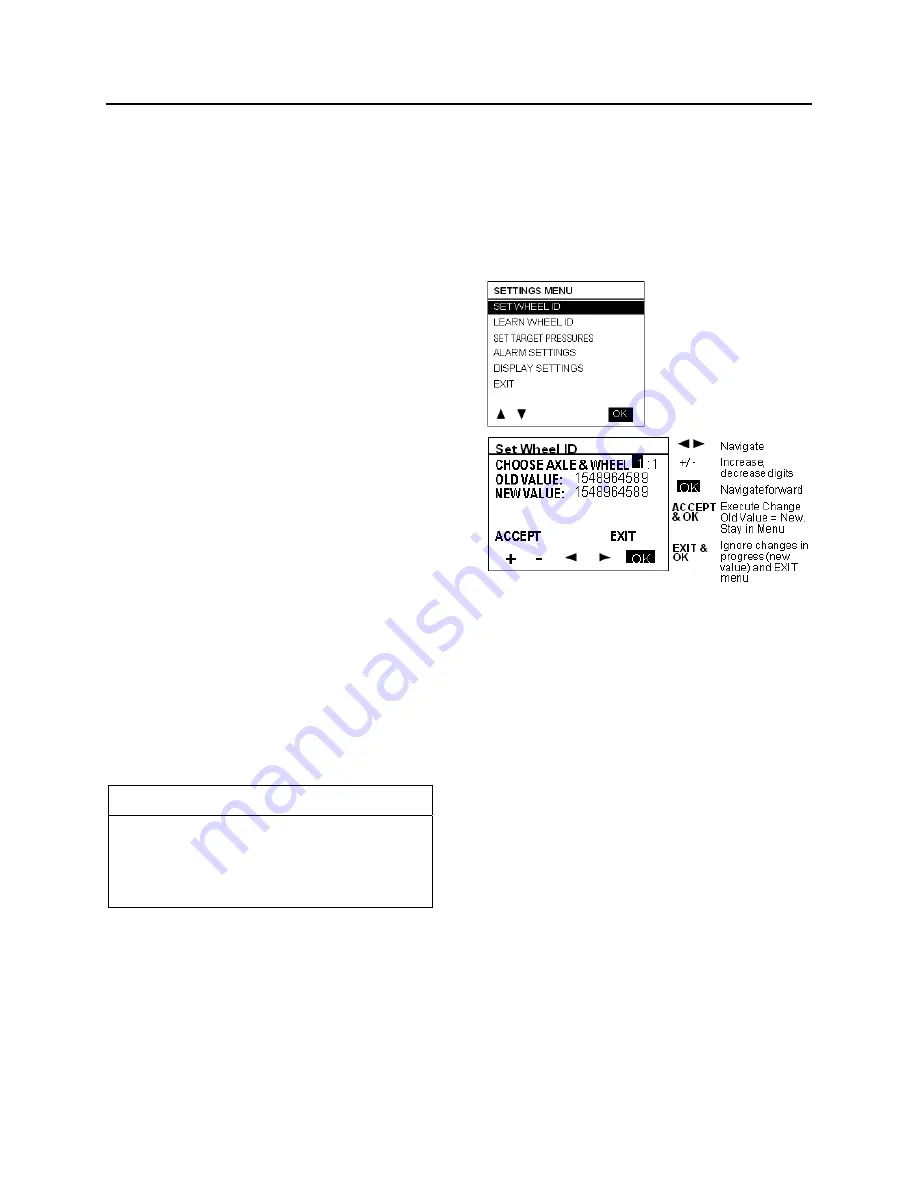

Settings Menu

Set Wheel ID

Learn Wheel ID

This menu allows learning new wheel sensors ID.

The user can learn only one wheel, several

wheels or all wheels of the vehicle. The sequence

automatically jumps to the next wheel such that

a user can initiate all wheels without having to

come back to the display between each wheel.

The display uses a pressure change as the

criteria to recognize which wheel sensor the

operator wants to get assigned to a given

location. The amount of pressure change

required is established at 2 PSI.

A pressure change of about 3 PSI is needed to

wake up a sensor and then an extra amount of

pressure change of 2 PSI is needed to trigger the

display. The operator has to create a pressure

change by at least 6 PSI and then wait for the

display to recognize the pressure change. The

wait time correspond to the sensor sampling

rate.

When entering the menu, the axle 1, wheel 1 is

selected by default as a starting point for the

learning. The user can select another axle with

+/- , move the cursor to the wheel number with

the right arrow and select another wheel with

the +/- or move the cursor down to the start

learning button.

Summary of Contents for H 2018 Series

Page 1: ...COACH MANUFACTURER OPERATOR S MANUAL H SERIES COACHES PA1628 January 2018 ...

Page 8: ......

Page 10: ......

Page 14: ......

Page 30: ......

Page 114: ......

Page 217: ...TECHNICAL INFORMATION 9 5 PA1628 H3 41 H3 45 Operator s Manual H3 45 OVERALL DIMENSIONS 18525 ...

Page 232: ......

Page 236: ......

Page 256: ......