7-12 SAFETY FEATURES AND EQUIPMENT

PA1628 H3-41, H3-45 Operator’s Manual

3.

Remove the wheel nuts and remove the

wheel;

4.

Mount the spare wheel over the studs, being

careful not to damage the stud threads;

5.

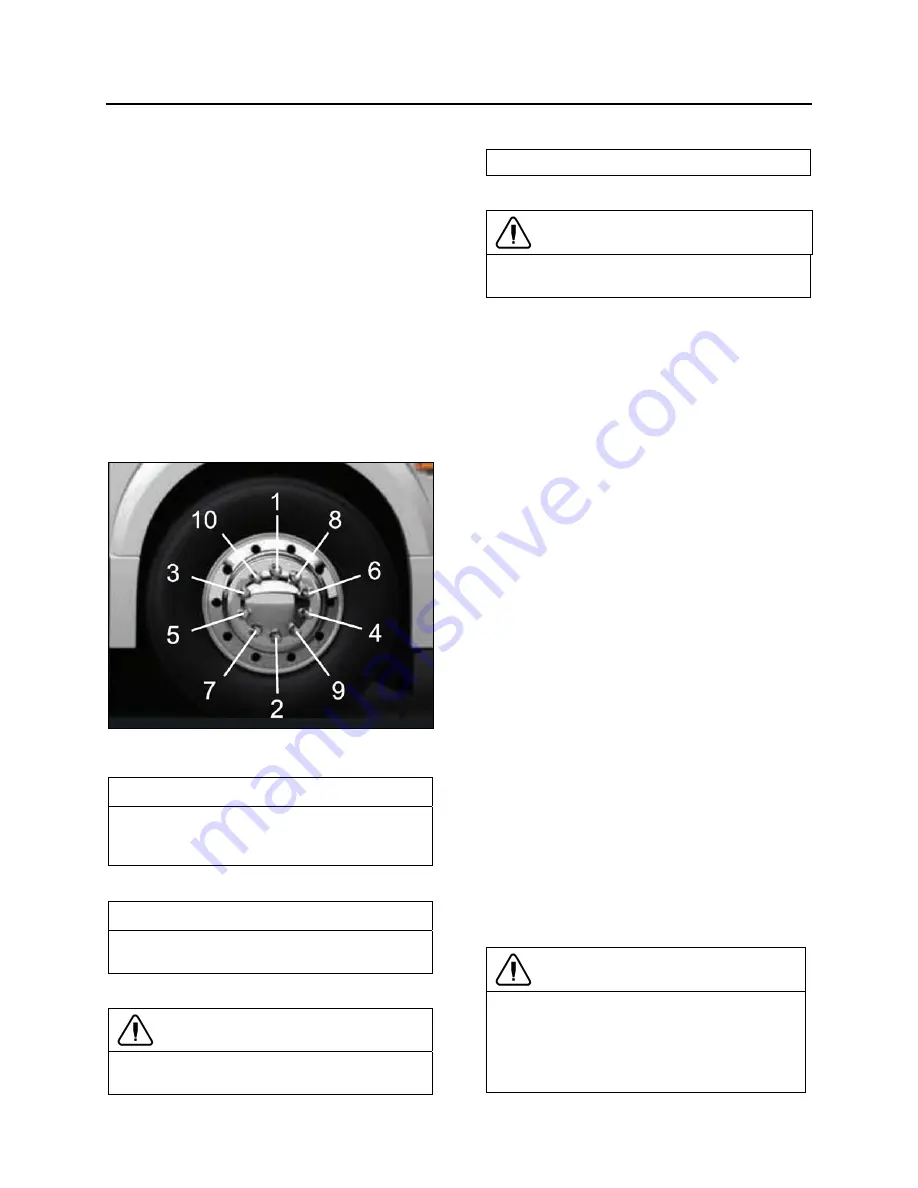

Screw in the wheel nuts according to the

sequence shown in the following figure and

tighten slightly more and repeat the

sequence a few times to position the wheel

correctly. Once tightening induces wheel

spin, lower the coach for final tightening;

6.

Tighten the nuts progressively in the

sequence shown. Final tightening should be

done using a torque wrench. Dry tightening

torque is 450 – 500 lbf-ft (610 – 680 Nm)

for steel as well as for aluminum wheels.

TIGHTENING SEQUENCE

13018

NOTE

Periodically check the spare tire inflation

pressure. Tire pressure should be the

maximum pressure specified in the chart.

NOTE

Periodically check that the spare is securely

fastened in its compartment.

CAUTION

Before driving, be sure the flat tire, track, jack

and tools are securely reinstalled in their

respective compartments.

CAUTION

Check that the bumper is securely closed

shut before driving.

SUPER SINGLE TIRE REPLACEMENT

Increase tire pressure to 125 lbs/in

2

(862 kPa) if

you are using the supplied 365/70 R 22.5 spare

tire to replace a super single tire on the drive

axle.

In this particular configuration, spare wheel is to

be used for emergency situation only and for

temporary use.

Do not exceed 50 mph (80 km/h).

Repair and re-install original super single

wheel and tire as soon as possible.

Adapt your driving while riding with spare tire.

EMERGENCY AIR-FILL VALVES

The vehicle is equipped with two air system

emergency fill valves to supplement the air

system when air pressure is low and the engine

cannot be operated. One valve is located inside

the front service compartment. The other valve

is located inside the engine compartment.

Both air system emergency fill valves are fitted

with standard tire valve stems. The air systems

can be filled using any standard external air

supply line. The fill valve located in the engine

compartment supplies air for all systems

(brakes, suspension and accessories). The fill

valve located in the front service compartment

supplies air for accessories only.

CAUTION

Air filled through the two emergency fill

valves will pass through the standard air

filtering-drying system. Do not fill air at any

other location. Do not exceed 120 psi (827

kPa).

Summary of Contents for H 2018 Series

Page 1: ...COACH MANUFACTURER OPERATOR S MANUAL H SERIES COACHES PA1628 January 2018 ...

Page 8: ......

Page 10: ......

Page 14: ......

Page 30: ......

Page 114: ......

Page 217: ...TECHNICAL INFORMATION 9 5 PA1628 H3 41 H3 45 Operator s Manual H3 45 OVERALL DIMENSIONS 18525 ...

Page 232: ......

Page 236: ......

Page 256: ......