CARE AND MAINTENANCE 8-25

PA1628 H3-41, H3-45 Operator’s Manual

Step 3: Engine Compartment

Check engine and surrounding areas for

coolant, oil and fuel leaks.

Check wiring harness for signs of damage.

Check for loose, worn or broken belts.

Check belts tension adjustment.

Check engine crankcase oil level, add if

necessary.

Check Allison transmission fluid level (can

also be checked from push-button shift

selector), add if necessary.

Check coolant surge tank fluid level, add if

necessary.

Check air cleaner restriction indicator, replace

air cleaner when red signal locks in full view.

Check stop light, tail light, directional signal

light and back-up light assembly, they should

be clean.

Step 4: Rear Left Side of the Coach

Check condition of wheels and rims.

Especially look for cracks, missing nuts, bent

or broken studs.

Check that baggage doors and service

compartment doors close properly. Check for

good tightness and fit.

Check condition of tires: properly inflated, no

serious cuts, bulges, tread wear or any signs

of misalignment; valve stems not touching

wheels or rims; valve caps in place and no

objects stuck between the wheels.

Step 5: Front Left Side of the Coach

Check condition of wheel rim. Especially look

for cracks, missing nuts, bent or broken

studs.

Check condition of tire: properly inflated, no

serious cuts, bulges, tread wear or any signs

of misalignment; valve stem not touching

wheel or rim; valve cap in place.

Check windshield and headlights washer

reservoir fluid level and add if necessary.

Drain accessory air tank by opening drain

cock. Close drain cock when completed.

Step 6: Front of the Coach

Check for damage and clean if dirty.

Check windshield wiper arms for proper

spring tension.

Check wiper blades for any damage, “dead”

rubber and attachment to arm.

Check clearance and identification lights, they

should be clean.

Check high and low beams, they should be

clean. If equipped, check fog lights.

Check left and right directional signals, they

should be clean.

Check to see that there is no mud, snow, ice

build-up or other obstruction in front of the

ACB radar sensor if applicable.

Step 7: Front Right Side of the Coach

Check condition of wheel rim. Especially look

for cracks, missing nuts, bent or broken

studs.

Check condition of tire: properly inflated, no

serious cuts, bulges, tread wear or any signs

of misalignment; valve stem not touching

wheel or rim; valve cap in place.

Step 8: Inside the Coach

Check for proper operation of the entrance

door.

Check steps; clean them if there is any

substance that makes them slippery, which

makes coach entry/exit hazardous.

Adjust and clean mirrors for adequate rear

view vision.

Verify proper operation of windshield wiper/

washer.

Check for fire extinguishers to make sure

they are ready for operation.

Check that emergency exit windows and roof

escape hatches can be opened then close all

windows and hatches securely

With engine running

Start engine and check for proper operation

of all gauges. Perform a telltale light test (see

Section 4

Controls And Instruments

).

Indicator lights and buzzers should all be OFF

before driving.

Summary of Contents for H 2018 Series

Page 1: ...COACH MANUFACTURER OPERATOR S MANUAL H SERIES COACHES PA1628 January 2018 ...

Page 8: ......

Page 10: ......

Page 14: ......

Page 30: ......

Page 114: ......

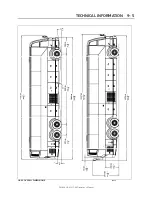

Page 217: ...TECHNICAL INFORMATION 9 5 PA1628 H3 41 H3 45 Operator s Manual H3 45 OVERALL DIMENSIONS 18525 ...

Page 232: ......

Page 236: ......

Page 256: ......