STARTING AND STOPPING PROCEDURE

4 - 3

Its major components include an Electronic Con-

trol Module (ECM), Electronic Unit Injectors (EUI)

and sensors. The ECM is the brain of the DDEC

system and is located on engine between pri-

mary and secondary fuel filters (curb side).

Within the ECM is the Electrically Erasable, Pro-

grammable, Read Only Memory (EEPROM) that

provides instructions for basic engine control

functions such as rated speed and power, engine

governing, cold start logic and diagnostics, plus

an engine protection system.

The ECM continuously monitors and analyzes

the DDEC system during engine operation with

electronic sensors. The Electronic Unit Injectors

(EUI) operate a principle which is similar to the

mechanical unit injector system. However, a so-

lenoid-operated control valve performs the injec-

tion timing much simpler and more precisely.

DDEC provides the capability to quickly diagnose

system malfunctions by a self-diagnostic system;

the self-diagnostic system monitors all engine

sensors and electronic components and recog-

nizes system faults and other engine-related

problems by providing the technician with a diag-

nostic code. Diagnostic codes are logged into the

ECM memory and can be read by performing

procedure outlined in page 5-9.

Jacobs Engine Brake

(optional)

The

Jacobs

brake is a diesel engine retarder that

uses the engine itself to aid in slowing and con-

trolling the vehicle. When activated, the

Jacobs

brake alters the operation of the engine's ex-

haust valves so that the engine works as a

power-absorbing air compressor. This provides a

retarding action to the wheels.

The engine brake is a vehicle slowing device, not

a vehicle-stopping device. It is not a substitute for

the service brake system. The vehicle's service

brakes must be used to bring the vehicle to a

complete stop.

Effectiveness of the engine brake system will

vary according to transmission range in use. The

engine brake system is more effective in lower

ranges and at higher engine speeds.

Warning:

When descending significant grades,

use service brakes as little as possible. If engine

does not slow vehicle to a safe speed, apply

service brakes and shift to a lower range. Let the

engine (and the engine brake) retard the vehicle.

Keep brakes cool and ready for emergency

stopping.

Note:

Engine brake is operative only when ac-

celerator pedal is released, and when engine

speed is over 900 rpm.

Each time the engine brake system is in opera-

tion, the stoplights will automatically light up.

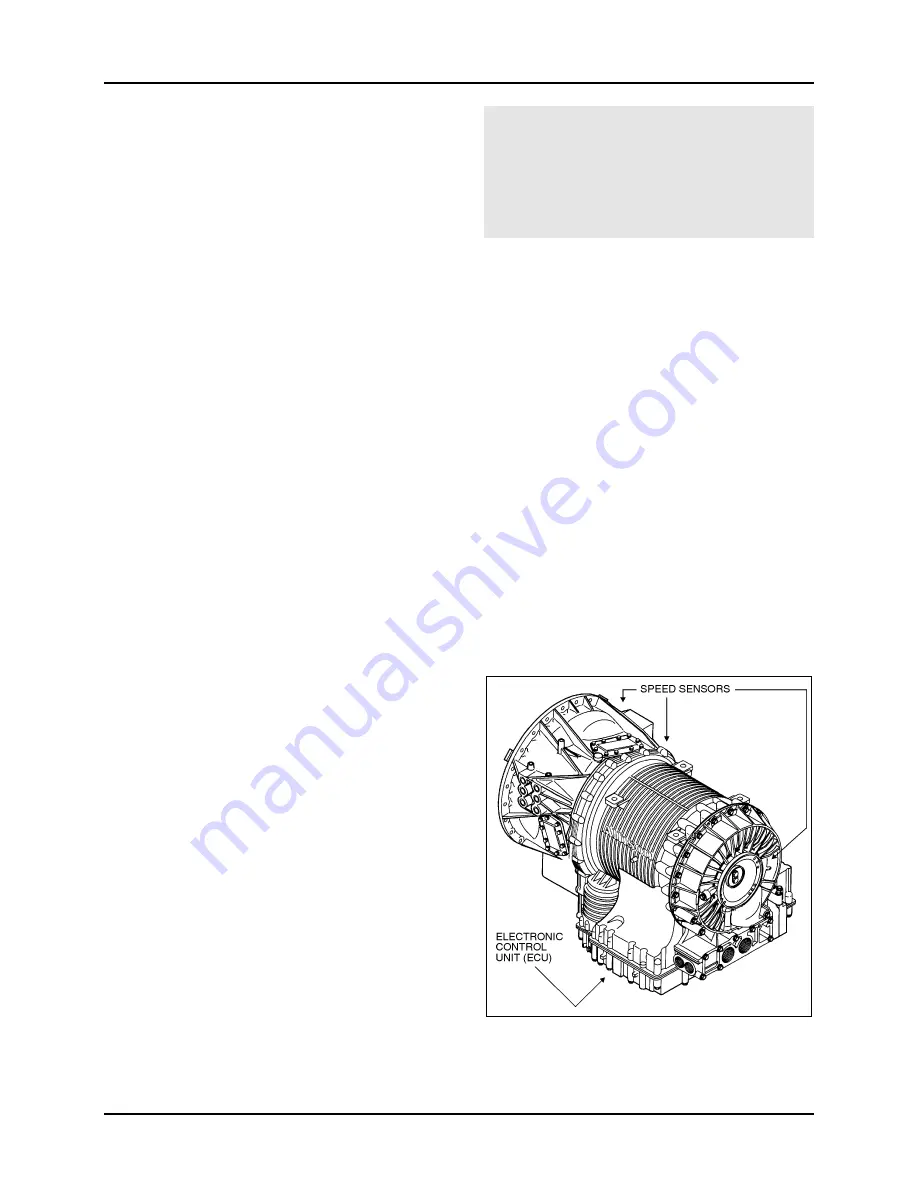

World Transmission

Electronic Control

System

The WT Electronic Control System consists of

five major components connected by wiring har-

nesses:

• Electronic Control Unit (ECU),

• Direct electronic communication from engine

Electronic Control Module (ECM),

• Three speed sensors,

• Push-button shifter,

• Control module which contains solenoid

valves and a pressure switch.

07020