Section 22: HEATING AND AIR CONDITIONING

PA1564

12

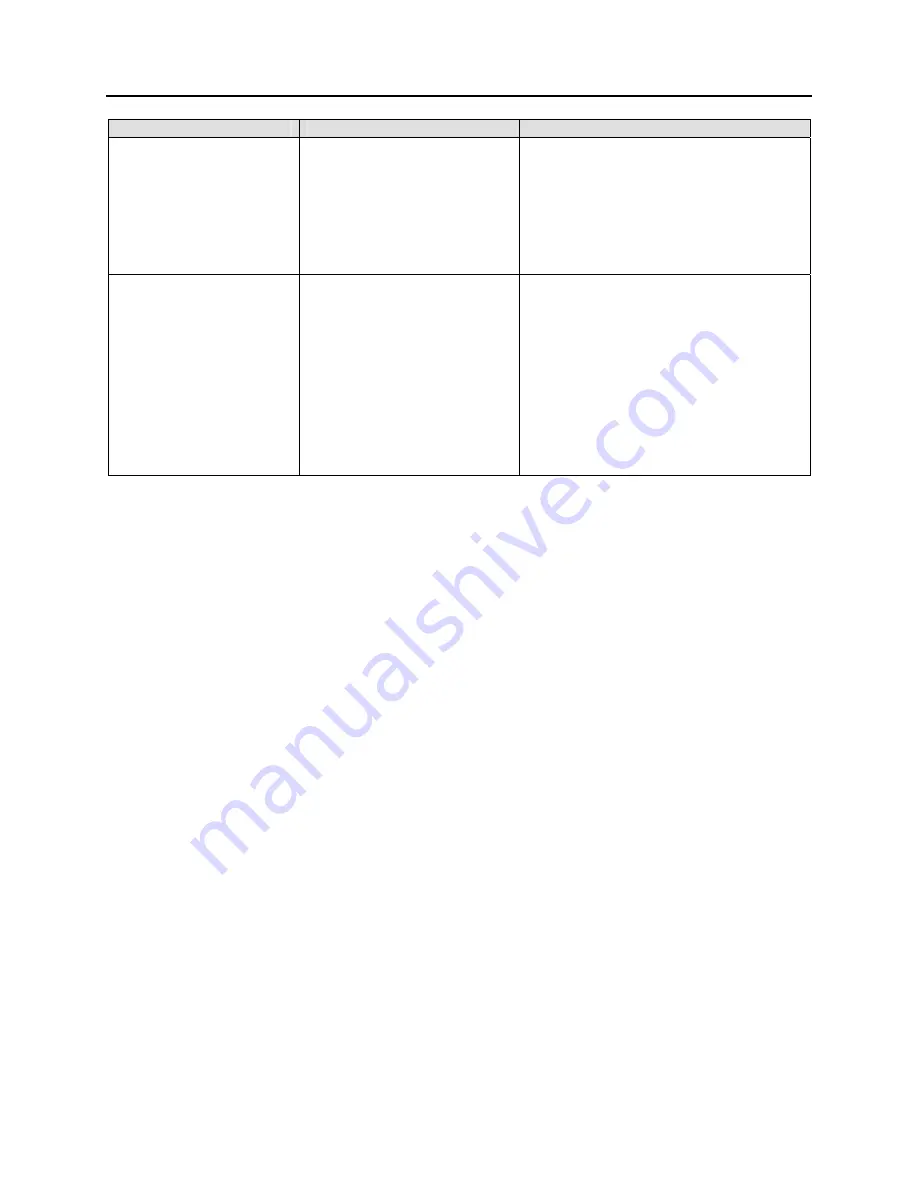

Problem/Symptom

Probable Causes

Actions

Select FAULT DIAGNOSTIC and

ELECTRICAL SYSTEM. The message

“Voltage Module A52, Value too Low,

Active” confirms a power problem on the

module

2. Check / reset circuit breaker CB7

3. Check / replace fuse F65

Evaporator fan not

functioning

Circuit breaker CB4 tripped

Module A54 is not powered or is

faulty

Faulty brushes

1. Check / reset circuit breaker CB4

2. Check the SYSTEM DIAGNOSTIC menu

of the message center display (MCD).

Select FAULT DIAGNOSTIC and

ELECTRICAL SYSTEM. The message

“Voltage Module A54, Value too Low,

Active” confirms a power problem on the

module

3. Check / reset circuit breaker CB4

4. Check / replace fuse F67 , F68

8. CENTRAL HVAC SYSTEM - AIR

CONDITIONING

The schematic of Figure 16 shows the central A/C

system and its components. The central system is

equipped with a 6 cylinder, 05G-134A Carrier

compressor with an air conditioning capacity of

7½ tons. The receiver tank and filter dryer are

mounted inside the condenser compartment.

XLII Converted vehicles may be supplied with a

central or small A/C system (Fig. 16 and 40). For

vehicles equipped with a small A/C system, refer

to paragraph 10: SMALL HVAC SYSTEM – AIR

CONDITIONING COMPONENTS further in this

section.

8.1 A/C

CYCLE

Refrigeration may be defined as "the transfer of

heat from a place where it is not wanted to a

place where it is unobjectionable". Components

required for a closed circuit refrigeration system

are shown in Figures 16 and 41.

The air conditioning system used on XLII series

vehicle is of the

"Closed"

type using

"R-134a".

1. The refrigerant flowing to the compressor is

compressed to high pressure and reaches a

temperature higher than the surrounding air.

It is passed through the air-cooled fins and

tubes of the condenser causing the hot, high

pressure gas to be condensed into a liquid

form.

2. The liquid refrigerant flows to the receiver

tank, then back to the condenser sub-

cooler. It leaves the condenser and passes

through a filter dryer where moisture, acids

and dirt are removed and then through a

moisture indicator which indicates if any

moisture is present in the system.

3. By its own pressure, the liquid refrigerant

flows through a thermal expansion valve

where the pressure drop causes the

refrigerant to vaporize in a vapor-liquid state

at a low temperature pressure.

4. The cold low pressure refrigerant passes

through the main and the driver’s

evaporator coils which absorbs heat from

the air passing over the fins and tubes, and

changes into gas. In this form, the

refrigerant is drawn into the compressor to

repeat the air conditioning cycle.

5. The success of the air conditioning system

depends on retaining the conditioned air

within the vehicle. All windows and intake

vents should be closed. An opening of

approximately 8 in

2

(5162 mm

2

) could easily

neutralize the total capacity of the system.

6. Other causes of inadequate cooling are

dirty coils or filter. Dirt acts as insulation and

is also serves as a restriction to the air flow.

Summary of Contents for LE MIRAGE XLII BUS SHELLS

Page 1: ...COACH MANUFACTURER MAINTENANCE MANUAL LE MIRAGE XLII BUS SHELLS PA1564 1ST EDITION...

Page 12: ...Section 00 GENERAL INFORMATION 10 PA1564 FIGURE 13 METRIC US STANDARD CONVERSION TABLE 00005...

Page 13: ...Section 00 GENERAL INFORMATION PA1564 11 FIGURE 14 CONVERSION CHART 00006...

Page 14: ......

Page 30: ......

Page 63: ...SECTION 01 ENGINE PA1564 33 FIGURE 13 POWER PLANT CRADLE INSTALLATION 01140...

Page 108: ......

Page 160: ......

Page 210: ......

Page 229: ...FAULT CODE MANUAL Created on 00 04 25 15 30 1 FAULT CODE MANUAL B7L B7TL B12...

Page 254: ......

Page 281: ......

Page 282: ......

Page 283: ......

Page 284: ......

Page 285: ......

Page 286: ......

Page 287: ......

Page 288: ......

Page 289: ......

Page 290: ......

Page 291: ......

Page 292: ......

Page 309: ......

Page 379: ...Section 12 BRAKE AND AIR SYSTEM PA1564 21 FIGURE 38 AIR OPERATED BRAKING SYSTEM WE...

Page 380: ...Section 12 BRAKE AND AIR SYSTEM PA1564 22 FIGURE 39 AIR OPERATED BRAKING SYSTEM W5...

Page 387: ...Section 12 BRAKE AND AIR SYSTEM PA1564 29 FIGURE 46 ABS 6S 5M CONFIGURATION...

Page 418: ...16 BW2158 Honeywell Commercial Vehicle Systems Company 4 2001 Printed in USA...

Page 422: ......

Page 430: ......

Page 438: ......

Page 445: ......

Page 458: ......

Page 534: ......

Page 540: ......

Page 543: ......

Page 660: ......

Page 661: ......

Page 662: ......

Page 663: ......

Page 664: ......

Page 665: ......

Page 666: ......

Page 667: ......

Page 668: ......

Page 669: ......

Page 670: ......

Page 671: ......

Page 672: ......

Page 673: ......

Page 674: ......

Page 675: ......

Page 676: ......

Page 677: ......

Page 678: ......

Page 679: ......

Page 680: ......

Page 681: ......

Page 682: ......

Page 683: ......

Page 684: ......

Page 685: ......

Page 686: ......

Page 687: ......

Page 688: ......

Page 689: ......

Page 690: ......

Page 691: ......

Page 692: ......

Page 693: ......

Page 694: ......

Page 695: ......

Page 696: ......

Page 697: ......

Page 698: ......

Page 699: ......

Page 700: ......

Page 701: ......

Page 702: ......

Page 703: ......

Page 704: ......

Page 705: ......

Page 706: ......

Page 707: ......

Page 708: ......

Page 709: ......

Page 710: ......

Page 711: ......

Page 712: ......

Page 713: ......

Page 714: ......

Page 715: ......

Page 716: ......

Page 717: ......

Page 718: ......

Page 719: ......

Page 720: ......

Page 721: ......

Page 722: ......

Page 723: ......

Page 724: ......

Page 725: ......

Page 726: ......

Page 727: ......

Page 728: ......

Page 729: ......

Page 730: ......

Page 731: ......

Page 732: ......

Page 733: ......

Page 734: ......

Page 735: ......

Page 736: ......

Page 737: ......

Page 738: ......

Page 739: ......

Page 740: ......

Page 741: ......

Page 742: ......

Page 743: ......

Page 744: ......

Page 745: ......

Page 746: ......

Page 747: ......

Page 748: ......

Page 749: ......

Page 750: ......

Page 751: ......

Page 752: ......

Page 753: ......

Page 754: ......

Page 755: ......

Page 756: ......

Page 757: ......

Page 758: ......

Page 759: ......

Page 760: ......

Page 798: ......

Page 886: ......

Page 900: ......

Page 902: ......

Page 904: ......

Page 910: ......

Page 916: ......

Page 920: ......

Page 924: ......

Page 926: ...PROCEDURE NO SAV00044 REVISION 00 Page 2 of 2 Slide out...

Page 930: ......

Page 932: ......

Page 934: ......

Page 940: ......

Page 944: ......

Page 946: ......

Page 954: ......

Page 976: ......

Page 988: ......

Page 992: ......

Page 996: ......

Page 1032: ......

Page 1038: ......

Page 1044: ......

Page 1064: ......

Page 1086: ...Section 22 HEATING AND AIR CONDITIONING PA1564 18 FIGURE 17 DOUBLE SWEEP EVACUATION SET UP...

Page 1118: ...Section 22 HEATING AND AIR CONDITIONING PA1564 50 FIGURE 54 HEATER LINE SHUTOFF VALVES WE...

Page 1124: ......

Page 1125: ...Compressor 62 11052 Rev A WORKSHOP MANUAL for MODEL 05G TWIN PORT COMPRESSOR R...

Page 1126: ...WORKSHOP MANUAL COMPRESSOR MODEL 05G TWIN PORT...

Page 1149: ...Compressor 62 11053 Rev B SERVICE PARTS LIST for MODEL 05G TWIN PORT COMPRESSOR 1 2 3 4 5 6 R...

Page 1177: ......

Page 1178: ......

Page 1179: ...1...

Page 1180: ...2...

Page 1181: ...3...

Page 1182: ...4...

Page 1183: ...5...

Page 1184: ...6...

Page 1185: ...7...

Page 1186: ...8...

Page 1187: ...9...

Page 1188: ......

Page 1212: ......

Page 1223: ...Section 26 XLII SLIDE OUT PA1564 11...

Page 1224: ...Section 26 XLII SLIDE OUT PA1564 12 FIGURE 16 KEYLESS BUSHING INSTALLATION INSTRUCTION...