Safety Features and Equipment

141

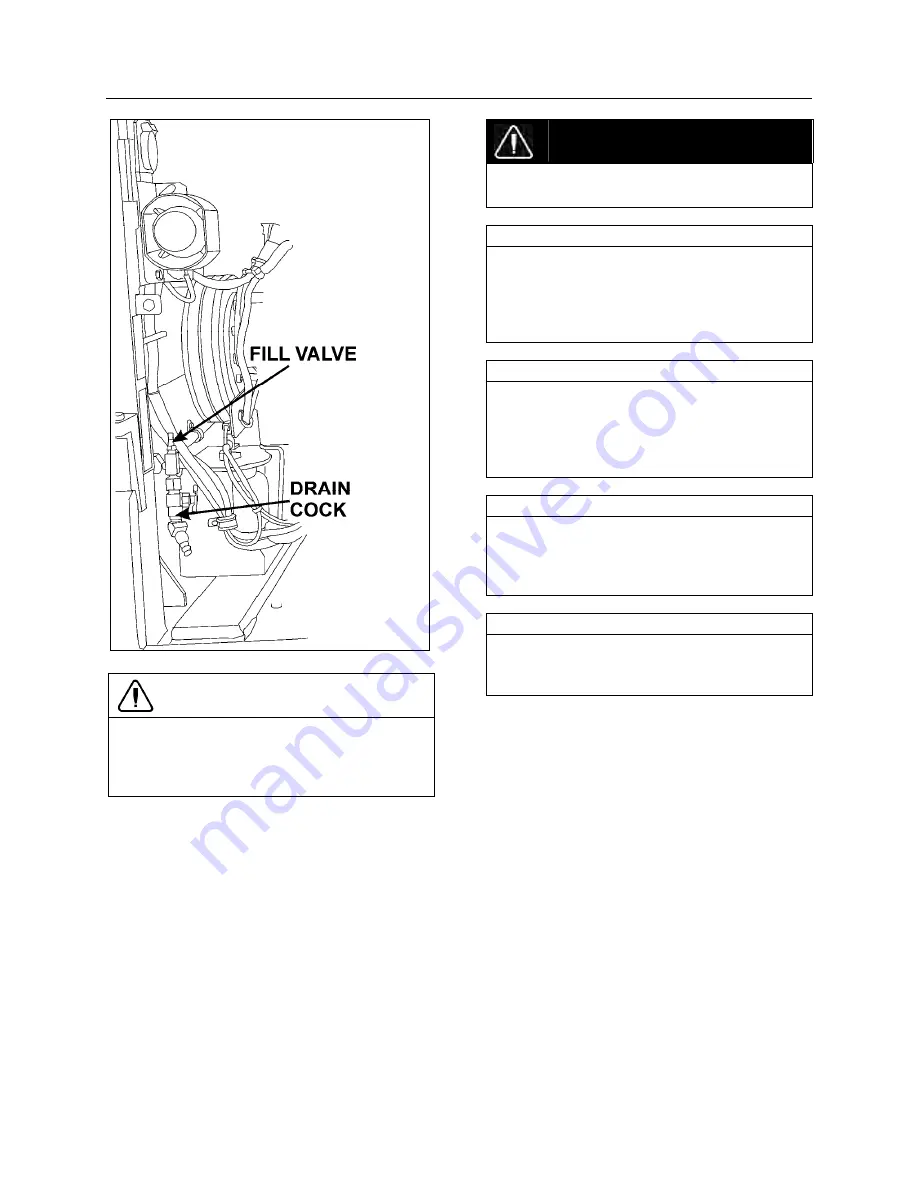

FILL VALVE IN ENGINE COMPARTMENT

12211

CAUTION

Air filled through the two emergency fill valves

will pass through the standard air filtering-

drying system. Do not fill air at any other

location. Do not exceed 120 psi (827 kPa).

EMERGENCY AND PARKING

BRAKES

During normal operation, if air pressure in any

brake circuit drops below 40 psi (276 kPa),

spring-loaded emergency brake will be

immediately applied at full capacity to the drive

axle wheels to stop the vehicle.

Spring-loaded parking brake is applied by pulling

up the control valve knob located on the L.H.

lateral console.

Parking brake is not designed to be used as a

service brake. For normal driving conditions, the

control valve knob must remain in the down

position.

DANGER

Always apply the parking brake before leaving

the driver's seat.

NOTE

Only use the parking brake to supplement the

service brake to stop the vehicle in emergency

conditions. The stopping distance will be

considerably longer than when using normal

service brake.

NOTE

Before releasing the parking brake by pushing

down the control valve knob, check the

pressure gauges to make sure that the brake

system air pressure is greater than or equal to

95 psi (655 kPa).

NOTE

A beep will sound if the ignition switch has

been turned off without applying the parking

brake. The same beep will sound if pressure

is still applied to the service brake pedal.

NOTE

The stoplights will automatically turn on when

the parking brake is applied and the ignition

key is turned to the ON position.

DAYTIME RUNNING LIGHTS

The inner lamps only also called high beams

illuminate automatically when the engine is

started and the parking brake is released to

serve as daytime running lights. The daytime

running lights provide added safety by making

the traveling vehicle more visible to other drivers

during the day.

The daytime running lights system turns the

headlights on when:

•

Engine

is

running;

•

Parking brake is released;

•

The exterior lighting switch is set to the OFF

position or pressed to the first position.

Summary of Contents for X3-45 2011

Page 1: ...COACH MANUFACTURER OPERATOR S MANUAL X3 45 COACH PA1581...

Page 4: ......

Page 6: ......

Page 10: ......

Page 24: ......

Page 128: ......

Page 134: ......

Page 171: ...Technical Information 165 X3 45 OVERALL DIMENSIONS SIDE ELEVATION 18673...

Page 172: ...Technical Information 166 X3 45 OVERALL DIMENSIONS TOP FRONT AND REAR VIEWS 18674...

Page 182: ......

Page 186: ......

Page 206: ......