Section 06: ELECTRICAL

PA1593

5

Problem:

DID displays the fault "Elec. Horn

SW61 SW62; shorted to ground" as being

active.

a) Refer to wiring diagram index, and look for

"Multiplexed Device Index"

, pages B1-B8.

b) In first column DEVICE ID, look for device

SW61, SW62.

c) At device SW61,SW62, find the fault

message, the minimum condition to activate,

other inputs involved in logic, the multiplex

module related to switch 61 and switch 62,

the connector and pin number on the

module and the page on which to find the

corresponding diagram.

d) Once the problem corrected, the DID still

shows the fault as being active. You have to

leave the

Fault Diagnostics

menu, wait

approximately 20 to 30 seconds and then

return to

Fault Diagnostics

to request a

new diagnostic of the

Electrical System

from the MCM. The DID should display the

fault as being inactive.

1.1.2 Testing

Circuits

A careful study of the wiring diagrams should be

made to determine the source and flow of

current through each circuit. When a circuit is

thoroughly understood, a point-to-point check

can be made with the aid of the applicable

wiring diagrams. Any circuit can be tested for

continuity or short circuits with a multimeter or a

suitable voltmeter.

All electrical connections must always be kept

clean and adequately tight. Loose or corroded

connections can result in discharged batteries,

difficult starting, dim lights and improper

functioning of other electric circuits. Inspect all

wiring connections at regular intervals. Make

sure knurled nuts on all amphenol-type plugs

are securely tightened. Knurled nuts on the

plastic amphenol-type connectors will click into a

detent when properly tightened. Line

connectors, who have the side locking tabs,

must have the locks latched in place to ensure a

proper electrical connection.

1.2

WIRE SIZES AND COLORS

Each wire in the electrical system has a specific

size as designated on the wiring diagram. When

replacing a wire, the correct size must be used.

Never replace a wire with one of a smaller size.

The vehicle electrical system is provided with

different voltages. The insulation on each wire is

distinctly colored in order to determine visually

the wiring voltage and to assist in making

connectors. The wires are color coded as

follows:

Yellow Multiplex

modules

communication

CAN-H (twisted with green)

Green Multiplex

modules

communication

CAN-L (twisted with yellow)

Orange

Connected to multiplex outputs

White

Connected to multiplex inputs

Red

24 volt system

Yellow

12 volt system

Black grounded

wire

Blue

110 V ac system (live)

White

110 V ac system (neutral)

Green

110 V ac system (ground)

Orange

speakers (+) (

Coaches Only)

Brown

speakers (-) (

Coaches Only)

Grey spare

wire

NOTE

Wires are identified at each 2-4 inch (5-10 cm)

intervals by a printed number.

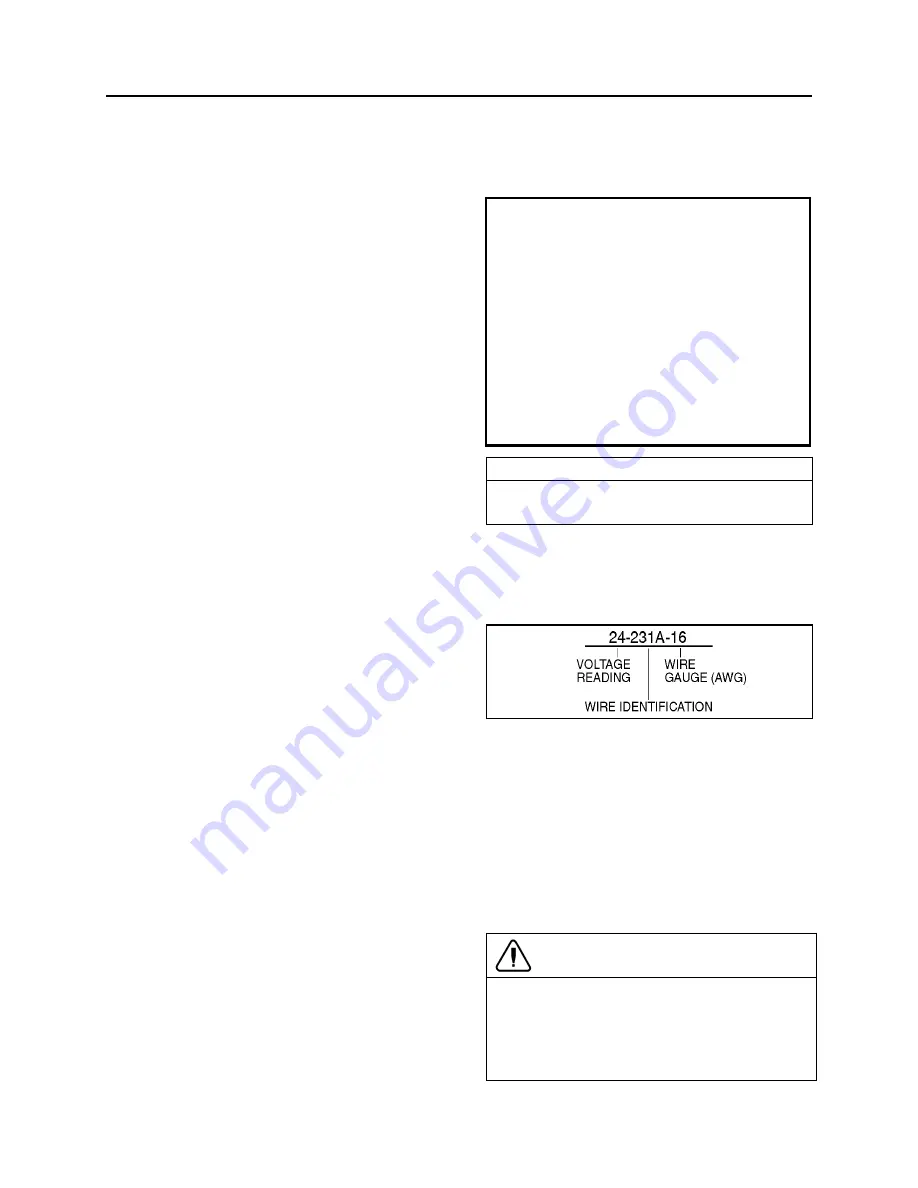

Each wire on a diagram is patterned to assist in

tracing and testing circuits. The wire number

identifies the voltage rating, the wire identification

number and the basic wire gauge as illustrated in

figure 1.

FIGURE 1: WIRE IDENTIFICATION

06048

1.3 SPARE

WIRES

When the vehicle leaves the factory, and even in

the case of a fully-equipped vehicle, an

important number of unconnected spare wires

are routed between the junction boxes.

Consequently

, for any connection of an additional

accessory, look in Wiring Diagram for “spare” wires

in the circuit number listing of pages E.1 thru E.8 to

determine the circuit number. Refer to page 8.1 in

Wiring Diagram to find location of these wires.

CAUTION

Wire size is calibrated according to the breaker or

fuse that protects it. When using a spare wire to

replace a damaged wire, assure that the spare wire

size is equal or larger than the wire being replaced.

Using a wire too small for the breaker or fuse

amperage might cause overheating of the wire.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...