Section 06: ELECTRICAL

PA1593

32

Headlight aim should be checked after installing

a new bulb. Aiming can be performed without

opening headlight assembly. Horizontal and

vertical aiming of each module is provided by

two adjusting screws that pivot the module in the

housing for proper alignment (fig. 27). There is

no adjustment for focus since the module is set

for proper focus during manufacturing assembly.

NOTE

Make sure headlight assembly is properly

positioned into its housing before securing

using fixing screw.

CAUTION

Use a soft cloth to clean the parking and front

turn signal lamp.

10.1.3 Headlight Adjustment

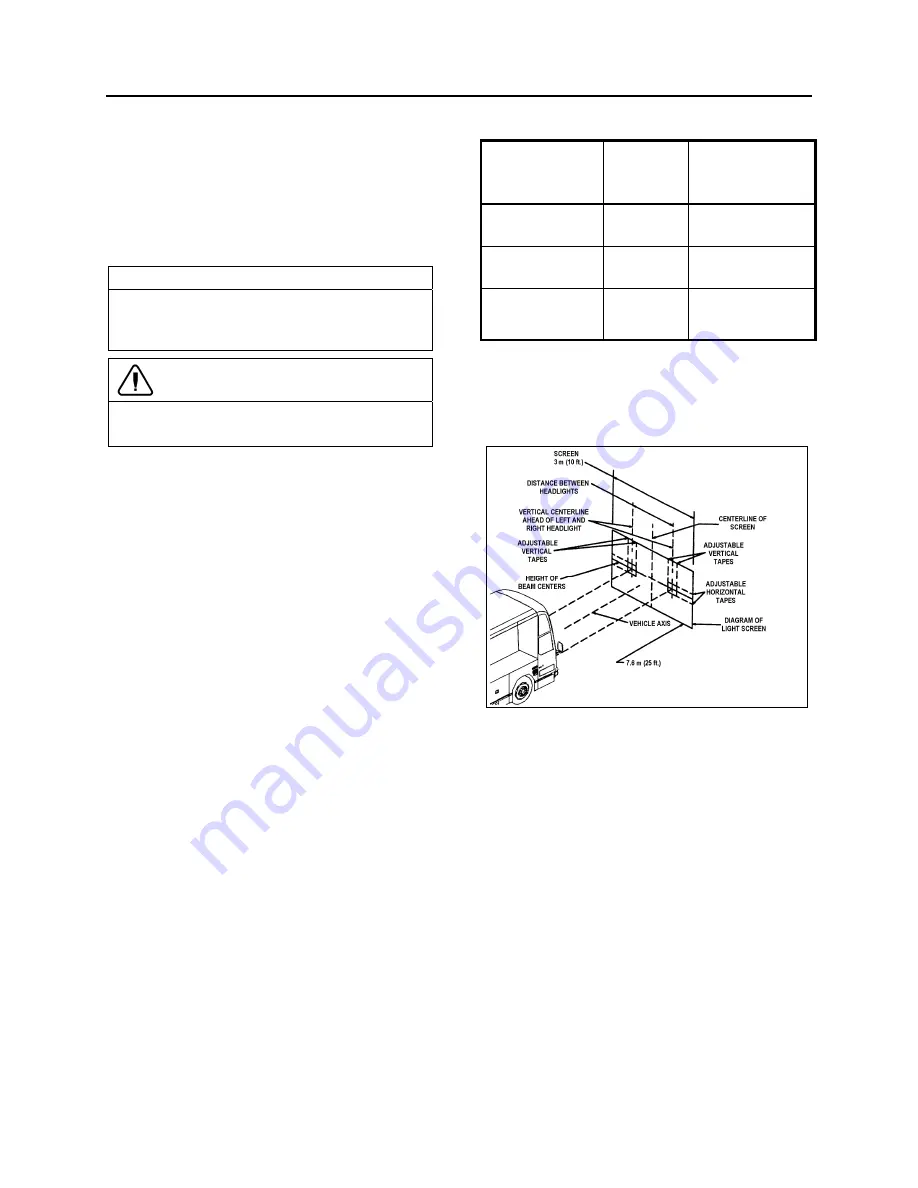

1. Headlight aiming and inspection can be

accomplished by visual means. This is done

on a screen located at a distance of 25 feet

(7,6 m) of the headlights. It should be of

adequate size with a matte-white surface

well shaded from extraneous light and

properly adjusted to the floor area on which

the vehicle stands. Provisions should be

made for moving the screen or its vertical

centerline so that it can be aligned with the

vehicle axis. In addition to the vertical

centerline, the screen should be provided

with four laterally adjustable vertical tapes

and two vertically adjustable horizontal

tapes.

2. The four movable vertical tapes should be

located on the screen at the left and right

limits called for in the specification with

reference to centerlines ahead of each

headlight assembly.

3. The headlight centerlines shall be spaced

either side of the fixed centerline on the

screen by ½ the lateral distance between

the light source centers of the pertinent

headlights. The horizontal tapes should be

located on the screen at the upper and

lower limits called for in the specification

with reference to the height of beam centers

and the plane on which the vehicle rests, not

the floor on which the screen rests (Fig. 30).

TABLE 1 – VERTICAL BEAM AIM GUIDELINES

Headlight

(centerline)

Mounting Height

Nominal

Vertical

Aim

Aim Inspection

Limits for Vertical

Aim

56 to 90 cm (22 to

36 inch)

0 Vertical

10 cm (4 inch) up to

10 cm ( 4 inch) down

90 to 120 cm (36 to

48 inch)

5 cm (2 inch)

down

5 cm (2 inch) up to 15

cm (6 inch) down

120 to 140 cm (48 to

54 inch)

6.4 cm (4

inch) down

4 cm (1.5 inch) up to

16.5 cm (6.5 inch)

down

4. The nominal vertical aim position on lower

beam headlights shall be adjusted based on

the headlight mounting height, from the

ground to the light source center of the

headlight, according to table1.

FIGURE 30: ALIGNMENT OF HEADLIGHT AIMING

SCREEN

06502

5. High beam headlights are aimed so that the

center of the high-intensity zone is located

at the horizontal and straight ahead

vertically (Fig. 31).

6. Low beam headlights are aimed so that the

top edge (the cutoff) of the high-intensity

zone is at the vertical location as per Table

1 and the left edge of the high-intensity zone

is at the vertical centerline of the headlight

(Fig. 32).

7. The inspection limits for high-beam

headlights shall be with the center of the

high-intensity zone from 10 cm (4 in) up to

10 cm (4 in) down; and, from 10 cm (4 in)

left to 10 cm (4 in) right on a screen at 7.6 m

(25 ft) (Fig. 33).

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...