Section 07: TRANSMISSION

PA1593

5

After 2 minutes, the display will flash one of the

codes shown below:

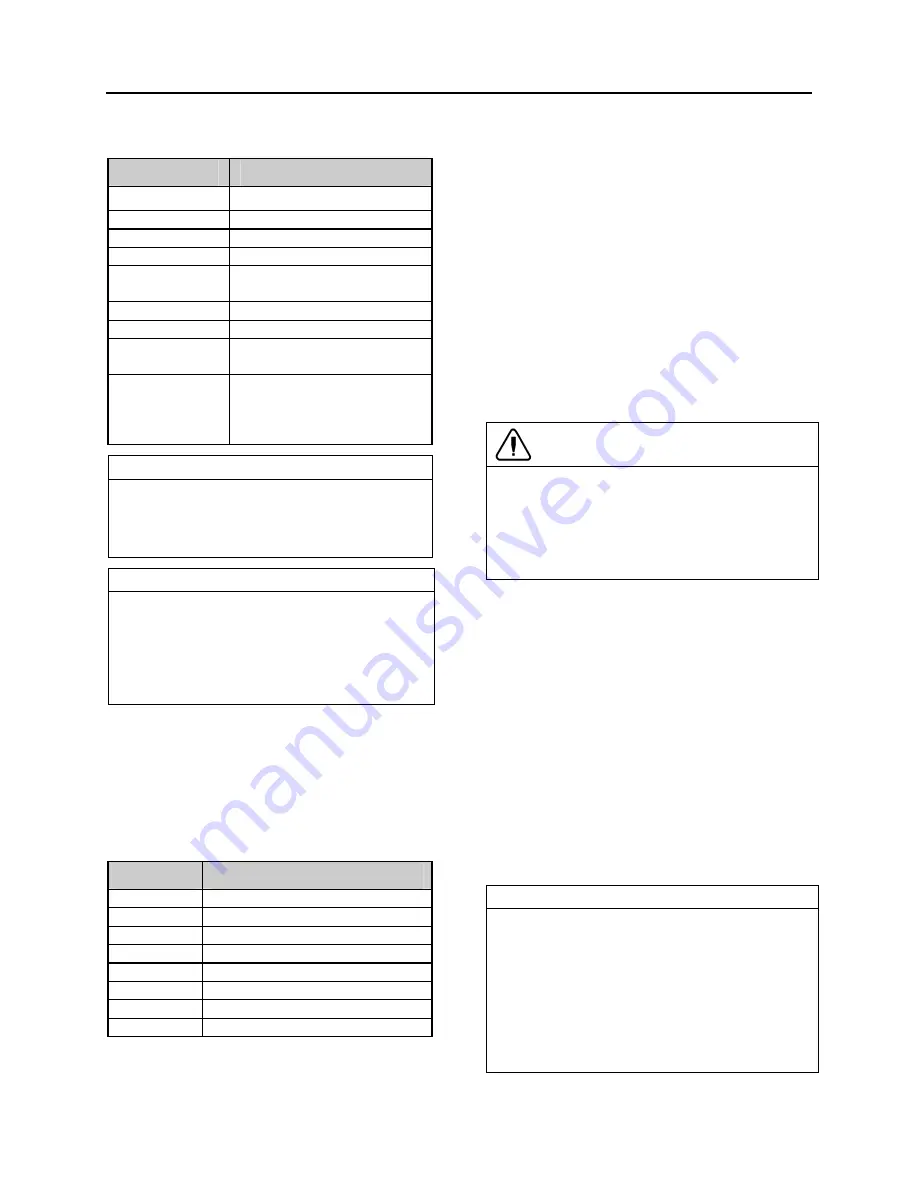

CODE

CAUSE OF CODE

O L…O K

Oil level is correct

O L…L O… 1

Oil Level is LOw 1 quart

O L…L O… 2

Oil Level is LOw 2 quart

O L…L O… 3

Oil Level is LOw 3 quarts

O L…L O… 4

Oil Level is LOw 4 or more

quarts

O L…H I… 1

Oil Level is HIgh 1 quart

O L…H I… 2

Oil Level is HIgh 2 quarts

O L…H I… 3

Oil Level is HIgh 3 or more

quarts

O L… – (fc)

Oil Level is invalid. Source

of invalid reading is

defined by a two-character

fault code (fc)

NOTE

Note that the quantities LO 4 and HI 3 are the

largest values displayed and that the actual

variation in oil level may exceed these

numbers.

NOTE

Failure to meet one of the above parameters

will stop the two minute countdown. One of

the codes shown hereafter will indicate the

cause of the countdown interruption. Once all

parameters are met, the countdown will

continue from where it left off.

If the fluid level check cannot be completed, an

Invalid for Display fault is reported. This

condition is reflected by the display of "OL",

followed by “–“, followed by one or two additional

characters. The displayed characters define the

cause of the fault, which may be either a system

malfunction or an improper condition for

conducting the check.

CODE

CAUSE OF CODE

OL…-…0X

Waiting period is not complete

OL…-…EL

Engine speed (rpm) too low

OL…-…EH Engine speed (rpm) too high

OL…-…SN N (neutral) must be selected

OL…-…TL

Sump oil temperature too low

OL…-…TH Sump oil temperature too high

OL…-…SH Output shaft rotation

OL…-…FL Sensor

failure

To exit the Oil Level Display Mode, press any

range button: “R”, “N” or “D” at any time.

3.3 IMPORTANCE OF PROPER FLUID

LEVEL

It is important that the proper fluid level be

maintained at all times because the

transmission fluid cools, lubricates, and

transmits hydraulic power. If the fluid level is too

low, the converter and clutches do not receive

an adequate supply of fluid. If fluid level is too

high, the fluid can aerate, causing the

transmission to shift erratically or overheat.

3.4

KEEPING OIL CLEAN

Oil must be handled in clean containers, fillers,

etc., to prevent foreign material from entering the

transmission. Place the dipstick on a clean

surface area while filling the transmission.

CAUTION

Containers or fillers that have been used to

handle antifreeze or engine coolant must

NEVER be used for handling transmission fluid.

Antifreeze and coolant solutions contain

ethylene glycol that, if introduced into the

transmission, can cause the clutch plates to fail.

3.5 RECOMMENDED

AUTOMATIC

TRANSMISSION FLUID

Hydraulic fluids used in the transmission are

important influences on transmission

performance, reliability and durability.

Castrol

TranSynd™ Synthetic Fluid

and

DEXRON-III®

fluids are recommended for on-highway

applications.

TranSynd™

is a full synthetic transmission

fluid developed by Allison Transmission and

Castrol Ltd. This fluid meets Allison

specifications for Severe Duty and Extended

Drain Intervals. TranSynd™ is fully qualified to

the Allison TES295 specifications and is

available through Prevost Parts.

NOTE

The prognostics package requires the use of

TranSynd™ or an Allison approved TES-295

licensed fluid

in the transmission and Allison

High Capacity filters. If any other fluids or filters

are used, Prognostic mode

must be disabled

.

Prognostic information will not be accurate with

any other fluids or filters and could result in

missed maintenance activities resulting in

transmission damage.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...