Section 07: TRANSMISSION

PA1593

6

To be sure a fluid is qualified for use in Allison

transmission, check for the

DEXRON-III®

license number on the container or consult the

lubricant manufacturer. Consult your Allison

Transmission dealer or distributor before using

other fluid types.

Customers may use TranSynd™/TES 295

equivalent and extend drain intervals. Equivalent

TranSynd™ fluid must meet or exceed TES 295

requirements. Customers may choose from a

wide variety of approved Dexron-III® fluids.

Customers may choose from a wide variety of

approved non-TES 295 like Dexron-III

®

or

approved Schedule 1 TES-389 fluids.

The Transmission Fluid Operating Temperature

Requirements table lists the minimum fluid

temperatures at which the transmission may be

safely operated without preheating. Preheat with

auxiliary heating equipment or by running the

equipment or vehicle with the transmission in «N»

(Neutral) for a minimum of 20 minutes before

attempting range operation.

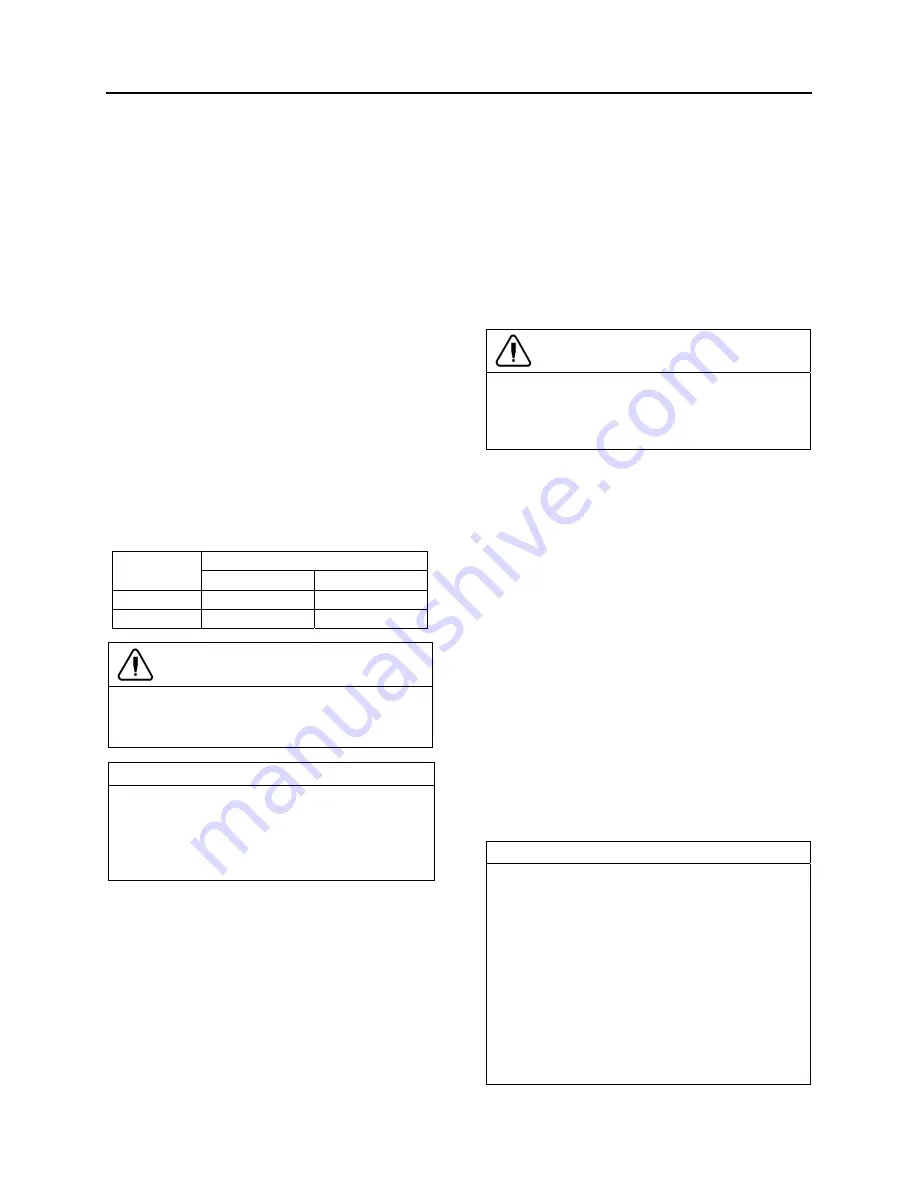

Transmission Fluid Operating Temperature Requirements

Fluid type

Minimum operating temperature

Celsius Fahrenheit

TranSynd™ -30

-22

DEXRON-III

®

-25

-13

CAUTION

Disregarding minimum fluid temperature limits

can result in transmission malfunction or

reduced transmission life.

NOTE

The use of an arctic preheat kit is

recommended at temperatures below -25ºF (-

32ºC). If a preheat kit is not available, the TCM

will restrict full operation until the sump

temperature is increased.

3.6 OIL

CONTAMINATION

At each oil change, examine the drained oil for

evidence of dirt or water. A nominal amount of

condensation will emulsify during operation of the

transmission. However, if there is evidence of

water; check the cooler (heat exchanger) for other

signs of leakage. This, however, may also

indicate leakage from the engine oil system.

3.7 METAL

PARTICLES

Metal particles in the oil (except for minute

particles normally trapped in the oil filter) indicate

damage has occurred in the transmission. When

these particles are found in the sump, the

transmission must be disassembled and closely

inspected to find the source. Metal contamination

will require complete disassembly of the

transmission and cleaning of all internal and

external circuits, coolers, and all other areas

where the particles could lodge.

CAUTION

If excessive metal contamination has occurred,

replacement of the oil cooler and replacement

of all bearings within the transmission is

recommended.

3.8 COOLANT

LEAKAGE

If engine coolant leaks into the transmission oil

system, immediate action must be taken to

prevent malfunction and possible serious

damage. The transmission must be completely

disassembled, inspected, and cleaned. All traces

of the coolant contamination must be removed.

Friction clutch plates contaminated with ethylene

glycol must be replaced.

3.9

CONTROL SYSTEM PROGNOSTICS

The transmission control system includes the

provision for the user to monitor various

transmission operating parameters.

Transmission operating parameters monitored

by the prognostics feature are:

o

Oil Life Monitor

o

Filter Life Monitor

o

Transmission Health Monitor

NOTE

The prognostics package requires the use of

TranSynd™ or an Allison approved TES-295

licensed fluid

in the transmission and Allison High

Capacity filters. If any other fluids or filters are

used, Prognostic mode

must be disabled

.

Prognostic information will not be accurate with any

other fluids or filters and could result in missed

maintenance activities resulting in transmission

damage.

Refer to TES 295 Approved Fluids list, found under

the Service/Fluids heading on the home page of

the Allison Transmission web site.

www.allisontransmission.com

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...