Section 07: TRANSMISSION

PA1593

11

4. To install filters, pre-lube and install the two O-

rings, the two square cut seals followed by the

filters (lube the O-ring in filter cartridge only)

into the filter compartment. Index each

filter/cover assembly to holes in channel

plate/sump. Push the cover assembly in by

hand to seat the seals.

CAUTION

Do not use bolts to draw the cover to sump.

This can damage the cover, seal, or sump.

5. Install twelve bolts and both covers, and then

tighten to 38-45 lbf-ft (51-61 Nm).

6. Inspect the drain plug and O-ring. Replace if

necessary. Reinstall the drain plug and tighten

to 18-24 lbf-ft (25-32 Nm).

7. Reinstall transmission protective panel

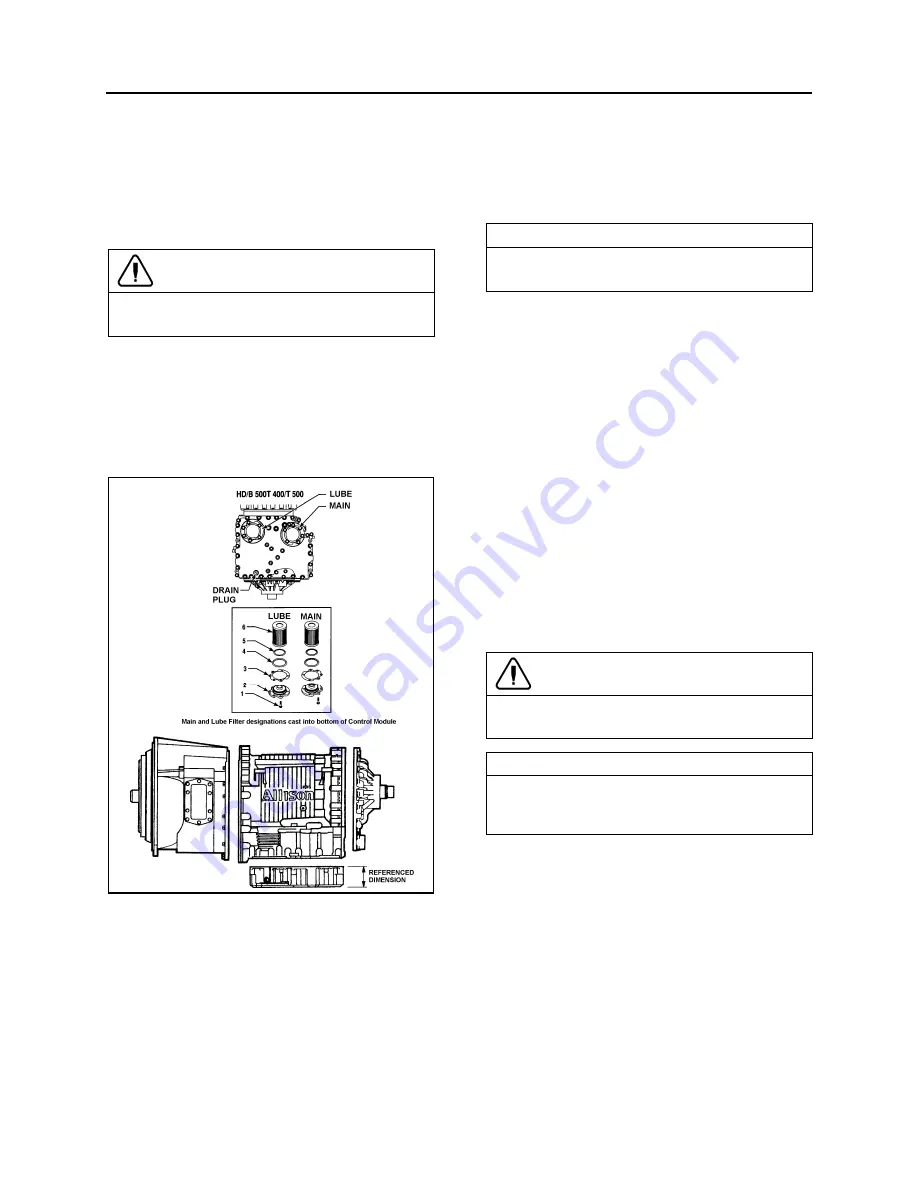

FIGURE 6: DRAIN PLUG AND FILTERS

07074

Fluid loss with filter change only

When changing main and lube filters at

recommended intervals, approximate fluid loss

for each filter as follows:

Main filter = 2 quarts (1.9 liters)

Lube filter =8 quarts (7.6 liters)

Refilling Transmission

The amount of refill fluid is less than the amount

used for the initial fill. Fluid remains in the

external circuits and transmission cavities after

draining the transmission.

NOTE

Quantities listed above are approximations and

do not include external oil cooler lines.

Using the oil level dipstick filler tube, refill with

24 US qts (23 liters) [28 US qts (26.5 liters) if

equipped with retarder] and check the oil level

using the

Fluid Level Check Using

Pushbutton Shift Selector

procedure in this

section.

4. ALLISON TRANSMISSION REMOVAL

The following procedure deals with the removal of

the Allison transmission without removing the

power plant cradle from vehicle. The methods

used to support the transmission and engine

depend upon conditions and available equipment.

1. Select transmission's "NEUTRAL" position,

apply parking brake, then set battery master

switch to the "OFF" position.

2. Jack up vehicle, then place safety supports

underneath body.

CAUTION

Only the recommended jacking points must be

used as outlined in Section 18, "BODY".

NOTE

For more clearance between the tag axle and

transmission, the tag axle may be unloaded

and jacked up or retracted (if applicable).

3. Remove engine splash guards and protective

panels surrounding transmission.

4.

Remove cross member from under

transmission.

5. Remove the transmission drain plug and allow

oil to drain. Inspect the drain plug washer and

replace it if necessary. Reinstall the drain plug

and tighten to 33-41 lbf-ft (45-56 Nm) (see

"3.10 OIL AND FILTER CHANGE"

in this

section.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...