Section 10: FRONT AXLE

PA1593

9

and a tendency for the wheels to return to the

straight-ahead position after taking a turn.

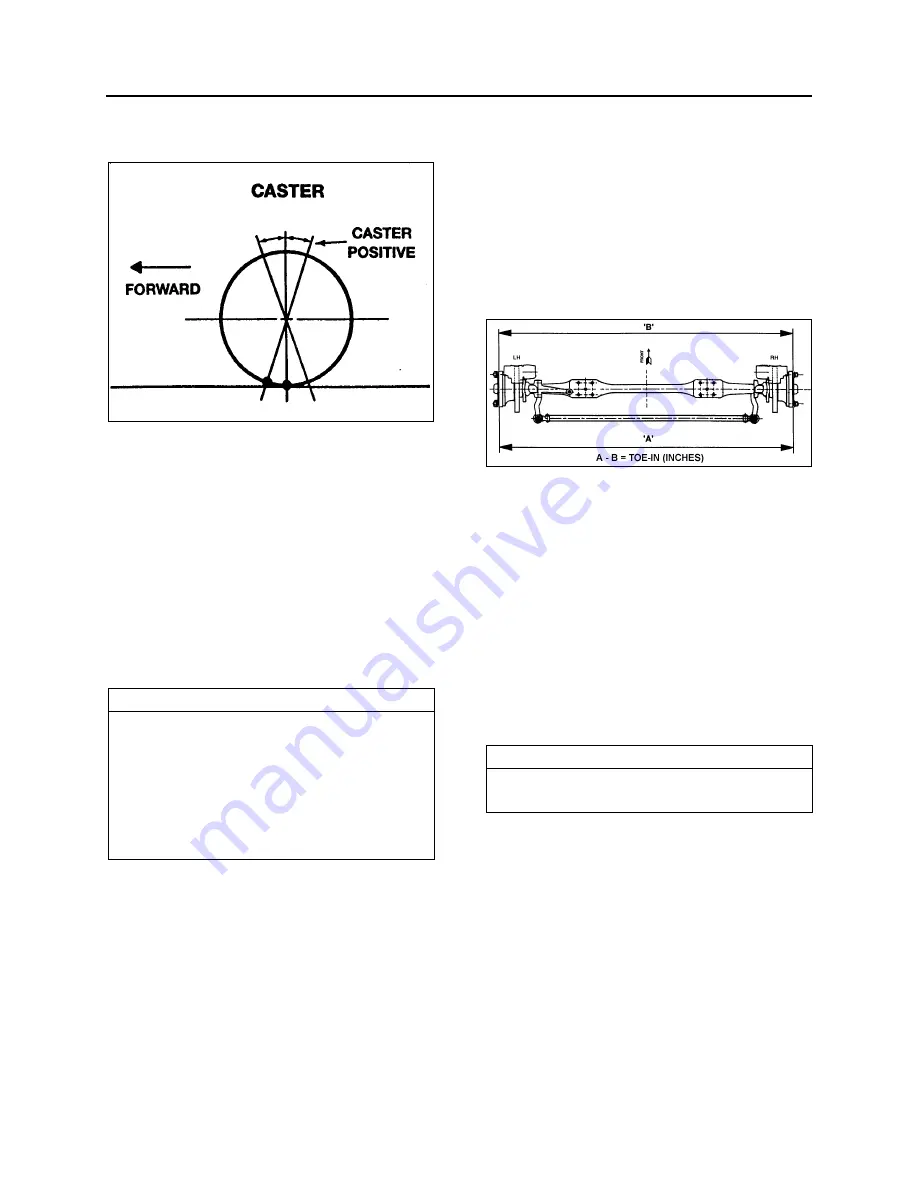

FIGURE 4: CASTER

10007

Excessive caster results in hard steering around

corners. A shimmy may also develop when

returning to the straight ahead position (pulling

out of curves).

Insufficient caster will cause wandering and

steering instability. Caster variations may be

caused by a bent axle, tilting or distortion of the

side suspension supports, damaged radius rod

bushings, or unequal tightening of the front and

rear suspension support bolts. Incorrect caster

must be corrected by replacing the damaged

suspension parts. A precision instrument should

be used to measure the caster.

NOTE

The caster of this vehicle is factory set and is

not adjustable. However, if after replacing

damaged parts or in case of improper caster

due to irregular setting, the front axle caster

needs adjustment; it can be adjusted by means

of shims (Prevost #110663) on the left-hand

side upper radius rod support in order to obtain

minor adjustment.

6.8

FRONT WHEEL TOE-IN

Wheel toe-in is the degree (usually expressed in

fractions of an inch) to which the forward part of

the vehicle front wheels are closer together than

the rear part, measured at wheel centerline height

with the wheels in the normal ‘’straight-ahead’’

position of the steering gear.

Incorrect toe-in results in excessive tire wear

caused by side slippage and also steering

instability with a tendency to wander. Toe-in may

be measured from the center of tire tread or from

the inside of the tires. Take measurements at

both front and rear of axle (see ’’A and ‘’B’’ in fig.

5).

When setting toe-in adjustment, the front

suspension must be neutralized; that is, all

component parts must be in the same relative

position when marking the adjustment as they

will be when in operation.

To neutralize the suspension, the vehicle must

be rolled forward, approximately ten feet.

FIGURE 5: TOE-IN MEASUREMENTS

10032

For toe-in specifications, refer to paragraph 8

‘’Specifications’’ in this section.

By rolling the vehicle forward, all tolerances in

the front suspension are taken up and the

suspension is then in its normal operating

position. Neutralizing the front suspension is

extremely important, especially if the vehicle has

been jacked up in order to mark the tires.

Otherwise, the front wheels will not return to

their normal operating position due to the tires

gripping the floor surface when the vehicle jack

is lowered.

NOTE

‘’Toe-in’’ measurements must be taken at the

horizontal axis of the wheel centerline.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...