Section 11: REAR AXLES

PA1593

2

1. DRIVE

AXLE

1.1 DESCRIPTION

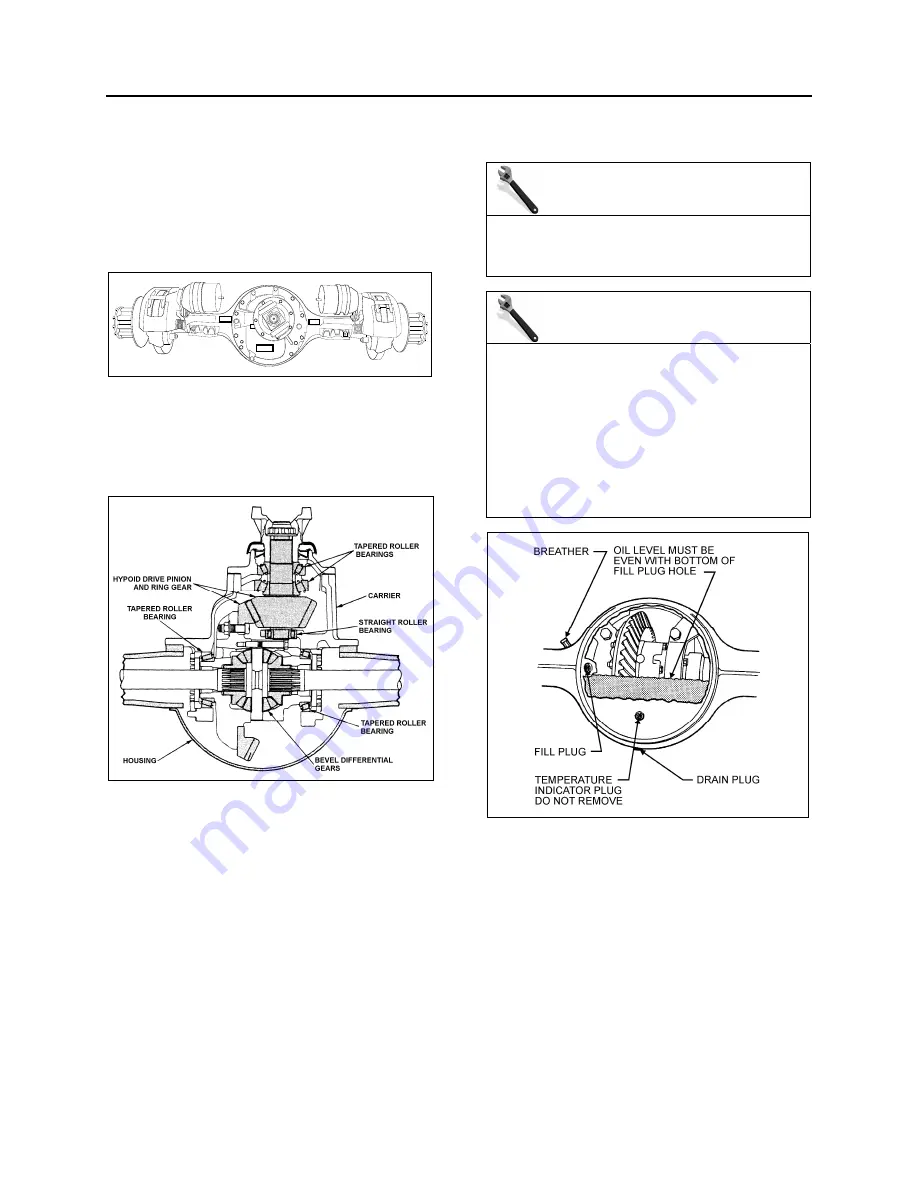

The Meritor drive axle is equipped with a single

reduction standard carrier mounted in front of

the axle housing. The carrier consists of a

hypoid drive pinion, a ring gear set and gears in

the differential assembly.

FIGURE 1: DRIVE AXLE

11019

A straight roller bearing (spigot) is mounted on

the head of the drive pinion. All other bearings in

the carrier are tapered roller bearings. When the

carrier operates, there is a normal differential

action between the wheels all the time.

FIGURE 2: DIFFERENTIAL ASSEMBLY

11024

Several speed ratios are available for the drive

axle. These ratios depend upon the motor and

transmission. Also, special applications may

suggest slightly different gear ratios.

1.2

DRIVE AXLE LUBRICATION

Use Multigrade gear oil 85W140 meeting MIL-

PRF-2105-E, tested and approved to SAE

J2360. If temperature drops below 10°F (-12°C),

80W90 should be used, and below -15°F (-

26°C), 75W90 should be used. Additional

lubrication information is covered in the Meritor

Technical Bulletin

"Approved Rear Drive Axle

Lubricants"

annexed to this section.

In extreme conditions, or for better performance,

fill with synthetic gear oil.

MAINTENANCE

Check oil level and add (if necessary) every

5,000 miles (8 000 km) or once a month,

whichever comes first (Fig. 3).

MAINTENANCE

Change differential oil and clean the

breathers, magnetic fill and drain plugs, every

25,000 miles (40 000 km) or once a year,

whichever comes first.

If using full synthetic gear oil, change

differential oil and clean the breathers,

magnetic fill and drain plugs, every 100,000

miles (160 000 km) or every two years,

whichever comes first.

FIGURE 3: DIFFERENTIAL HOUSING BOWL

11007

1.3 MAINTENANCE

Proper vehicle operation begins with preventive

maintenance, such as good differential use. The

most common types of drive axle carrier failures

are spinout, shock, fatigue, overheating and

lubrication. Avoid neglecting these points since

they would be the first steps to improper

maintenance, expensive repairs, and excessive

downtime.

Inspect the pinion oil seal, axle shaft flange and

carrier housing gaskets for evidence of lubricant

leakage. Tighten the bolts and nuts, or replace

the gaskets and seals to correct leaks.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...