Section 11: REAR AXLES

PA1593

7

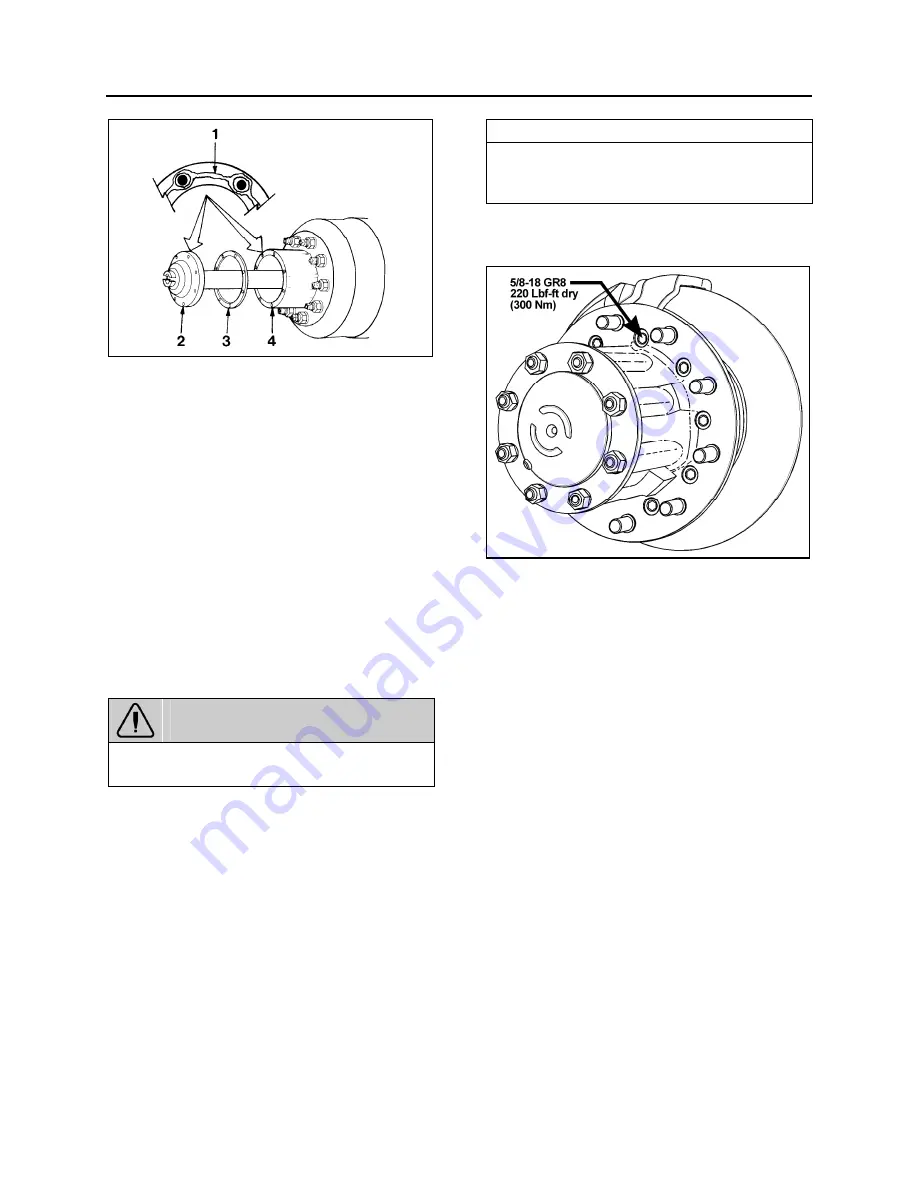

FIGURE 8: AXLE SHAFT INSTALLATION

11003

1 ................................................... Silicone sealant*

2 .............................................................. Axle shaft

3 ................................................................... Gasket

4 ............................................................. Wheel hub

1. Clean the mounting surfaces of both the axle

shaft flange and wheel hub where silicone

sealant will be applied. Remove all old

silicone sealant, oil, grease, dirt and moisture.

Dry both surfaces.

2. Apply a continuous thin bead of silicone

sealant* (Prevost P/N 680053) on the

mounting surfaces and around the edge of all

fastener holes of both the axle shaft flange

and wheel hub.

*

GENERAL ELECTRIC Silicone Rubber Adhesive Sealant

RTV 103 Black.

WARNING

Carefully read cautions and instructions on the

tube of silicone sealant and its packing.

3. Assemble components immediately to permit

the silicone sealant to compress evenly

between parts.

a. Place a new gasket and then install the

axle shaft into the wheel hub and

differential carrier. The gasket and flange

of the axle shaft must fit flat against the

wheel hub.

b. Install the tapered dowels at each stud

and into the flange of the axle shaft. Use

a punch or drift and hammer if needed.

c. Install the lock washers and nuts on the

studs. Tighten nuts to the correct torque

value.

NOTE

Torque values are for fasteners that have a

light application of oil on the threads (refer to

Meritor Maintenance Manual).

9/16-18 plain nut: 110 - 165 lbf-ft (149 -224 Nm)

5/8-18 plain nut: 150 - 230 lbf-ft (203 - 312 Nm)

FIGURE 9: TORQUE SPECIFICATION

2. TAG

AXLE

The tag axle is located behind the drive axle. It

carries a single wheel and tire on each side.

2.1

UNLOADING TAG AXLE

To reduce the turning radius, the air springs

pressure will be automatically reduced by 75%

when the coach is moving at speed lower than 5

mph (8 km/h) and with more than 1½ turn from

the steering.

2.2

RETRACTING TAG AXLE

The standard tag axle retraction system is

controlled by a valve located on the left lateral

console and enables unloading and raising the

tag axle (refer to the

"OPERATOR'S MANUAL"

for location of controls). This system has been

designed for the following purposes:

1. Shortening of wheelbase, thus allowing tighter

turning in tight maneuvering areas such as

parking lots or when making a sharp turn.

2. Transferring extra weight and additional

traction to the drive wheels on slippery

surfaces.

The tag axle service brakes operate only when

the axle is in normal driving (loaded) position.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...