Section 12: BRAKE AND AIR SYSTEM

4

X3-45 Commuter PA1593 DOB 2400-2489

Section 12 Updated Sept. 2015

1. AIR SYSTEM

The basic air system consists of an air

compressor, reservoirs, valves, filters and

interconnecting lines and hoses. It provides a

means for braking; operating controls and

accessories, and suspension (refer to Section

16,

"Suspension"

, for complete information on

suspension description and maintenance). An air

system schematic diagram is annexed in the

technical publications box provided with the

vehicle for better understanding of the system.

2. BRAKES

This vehicle uses both the service brake and

emergency/parking brake. The service brake air

system is divided into two independent circuits to

isolate front brakes from rear brakes, thus

providing safe braking in the event that one

circuit fails. Front axle brakes operate from the

secondary air system, while brakes on both the

drive axle and tag axle operate from the primary

air system.

NOTE

The tag axle service brake operates only when

the axle is in normal ride position (loaded and

down).

Furthermore, the brake application or release,

which is speed up by a pneumatic relay valve (R-

12), will start with the rear axles and will be

followed by the front axle, thus providing uniform

braking on a slippery road. The vehicle is also

equipped with an Anti-Lock Braking System

(ABS), which is detailed later in this section.

The drive axle is provided with spring-loaded

emergency/parking brakes, which are applied

automatically whenever the control valve supply

pressure drops below 40 psi (275 kPa).

3. AIR RESERVOIRS

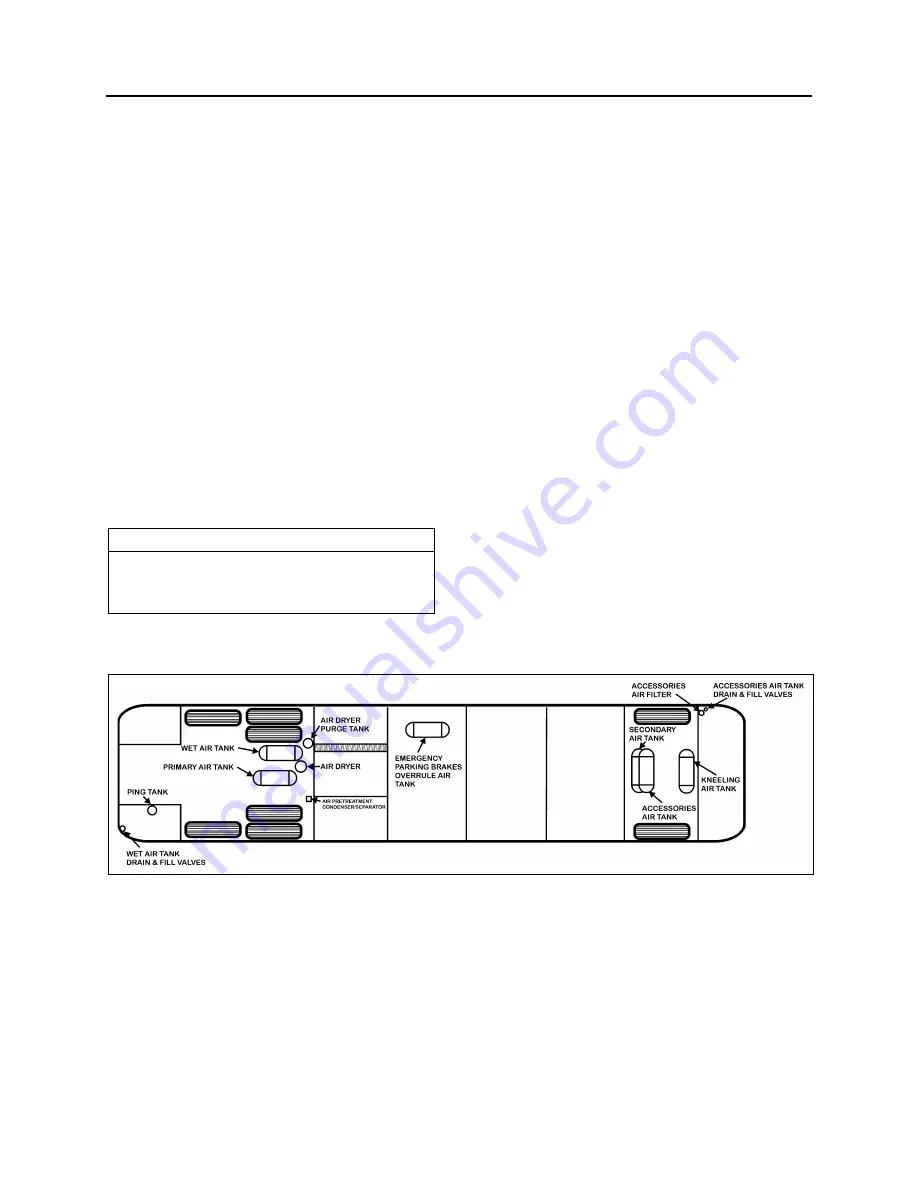

The air coming from the air dryer is first

forwarded to the wet air tank, then to the primary

(for the primary brake system), secondary (for

the secondary brake system), and accessory (for

the pneumatic accessories) air tanks (Fig. 1).

Two additional air reservoirs are installed on the

vehicle: the kneeling air tank and the parking

brakes overrule air tank.

3.1

MAINTENANCE

Ensure that the wet (main) air tank is purged

during pre-starting inspection. In addition, it is

good practice to purge this reservoir at the end

of every working day. The remaining reservoirs

must be purged at every 12,500 miles (or 20 000

km) or once every year, whichever comes first.

FIGURE 1: I-BEAM FRONT SUSPENSION AIR RESERVOIRS LOCATION

12213

3.1.1 Wet (Main) Air Tank

This reservoir, located above the L.H. wheel of

drive axle in the rear wheelhousing, is provided

with a bottom drain valve. A recommended

purge using the bottom drain valve should be

done every 12,500 miles (20 000 km), or once a

year, whichever comes first.

3.1.2 Primary Air Tank

This reservoir is located above the R.H. wheel of

the drive axle and is provided with a bottom drain

valve (Fig. 1). It is recommended to purge the

primary air tank every 12,500 miles (20 000 km)

or once a year, whichever comes first.

3.1.3 Accessory Air Tank

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...