Section 12: BRAKE AND AIR SYSTEM

6

X3-45 Commuter PA1593 DOB 2400-2489

Section 12 Updated Sept. 2015

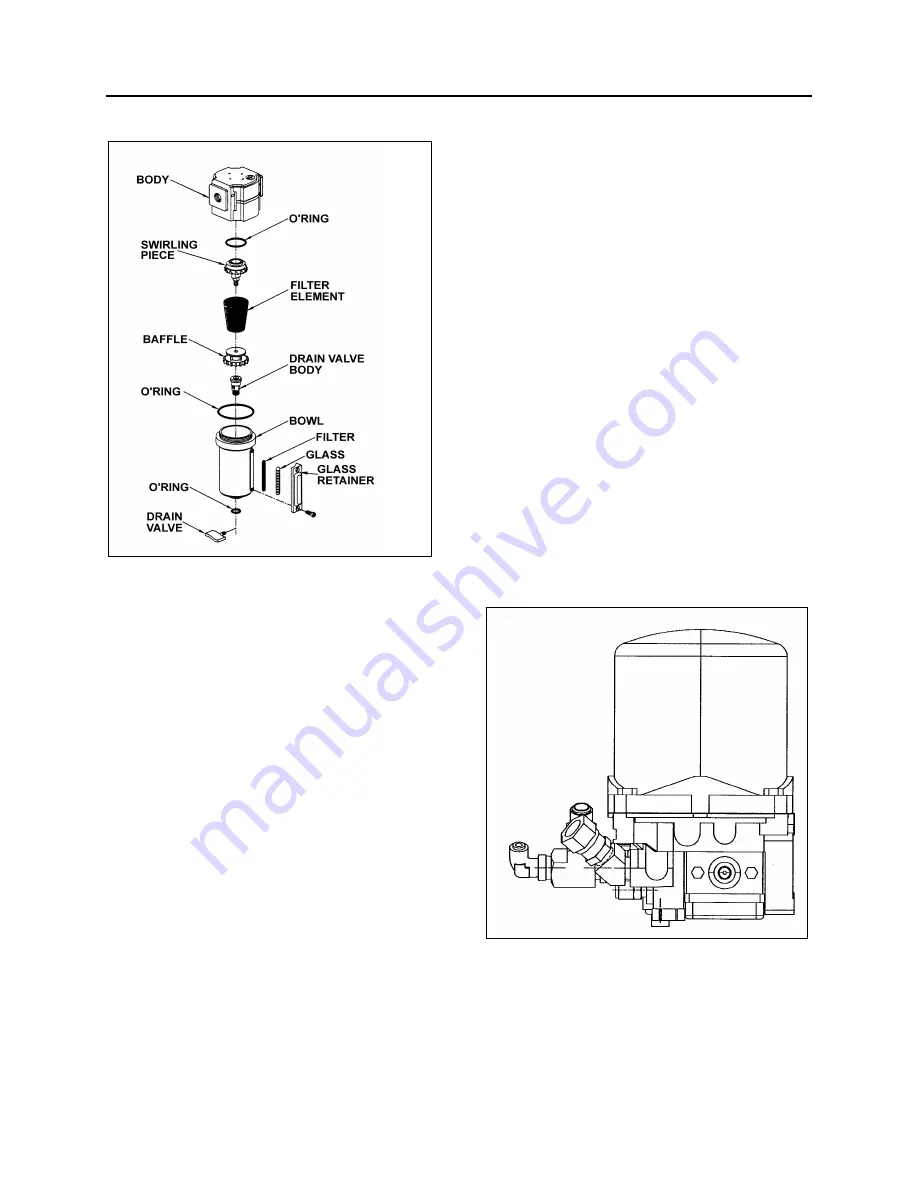

5. ACCESSORY AIR FILTER

FIGURE 4: ACCESSORY AIR FILTER

12088

This filter is located inside the front service

compartment (Fig. 3). Its main function consists

in filtering the air supplied to the accessory air

system, when connected to an external supply

line. Ensure filter is purged whenever supplying

the system with an external air line and at least

every 12,500 miles (20 000 km). To purge, open

drain valve (Fig. 4), let the moisture come out,

then close the drain valve.

5.1

FILTER ELEMENT REPLACEMENT

Replace filter element whichever of the following

occurs first: every 100,000 miles (160 000 km),

every two years, or whenever differential

pressure exceeds 15 psi (105 kPa) between filter

inlet and outlet ports. Check condition of all three

O-rings for damage. Replace when necessary

(Fig. 4).

5.2

CLEANING

Clean filter body and bowl with a warm water and

soap solution. Rinse thoroughly with clean water.

Blow dry with compressed air making sure the

air stream is moisture free and clean. Pay

particular attention to the internal passages.

Inspect all parts for damage and replace if

necessary.

6. AIR GAUGES (PRIMARY, SECONDARY

AND ACCESSORY)

The air pressure gauges, located on the

dashboard (see

"Operator's Manual"

), are

connected to the DC-4 double check valve,

located on the pneumatic accessory panel in the

front service compartment.

The latter is connected to the air lines running

from the primary and secondary air tanks, as

shown on the pneumatic system diagram

provided in the technical publications box. The

accessory air gauge is connected to the

accessory air tank using the drain valve

connector. The vehicle should never be set in

motion until the buzzer alarm and warning lights

turn off, i.e. when air pressure registers at least

66 psi (455 kPa). Moreover, if pressure drops

below 66 psi (455 kPa), the

"Low air pressure"

warning lights will turn on, and the

"Low air

pressure"

buzzer will sound. Stop the vehicle

immediately, determine and correct the cause(s)

of pressure loss. Check the gauges regularly

with an accurate test gauge. Replace the gauge

with a new unit if there is a difference of 4 psi (27

kPa) or more in the reading.

7. AIR FILTER/DRYER

FIGURE 5: HALDEX AIR FILTER DRYER

12194

The air filter/dryer is located in front of rear

wheelhousing (Fig. 1 & 5). Its purpose is to

remove moisture that could damage the air

system before the air enters the system

reservoir. The air filter/dryer also filters the air to

remove dirt, compressor oil, and other

contaminants that can damage the system.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...