Section 12: BRAKE AND AIR SYSTEM

10

X3-45 Commuter PA1593 DOB 2400-2489

Section 12 Updated Sept. 2015

supplied in the applicable booklet annexed at the

end of this section.

Item Description

Notes

1

Air Compressor

Wabco 636

2

O’Ring

3

Stud (3)

M12

4

Flange Nut (3)

Torque to 15lb-ft (20 Nm)

5

Nipple (2)

6

Hose Assembly

11.1

COMPRESSOR REMOVAL AND

INSTALLATION

1. Exhaust compressed air from air system by

opening the drain valve of each air tank.

2. Drain the engine cooling system. See

Section 5: "

Cooling System

".

3. Access the compressor by the engine R.H.

side compartment. Identify and disconnect

all air, coolant and oil lines from the

compressor assembly.

4. Remove the three compressor flange

mounting nuts.

5. Slide air compressor rearward to disengage

the hub from coupling. Remove the air

compressor.

Remove and retain the oil supply tube that

runs between the compressor and the engine

Reverse removal procedure for installation.

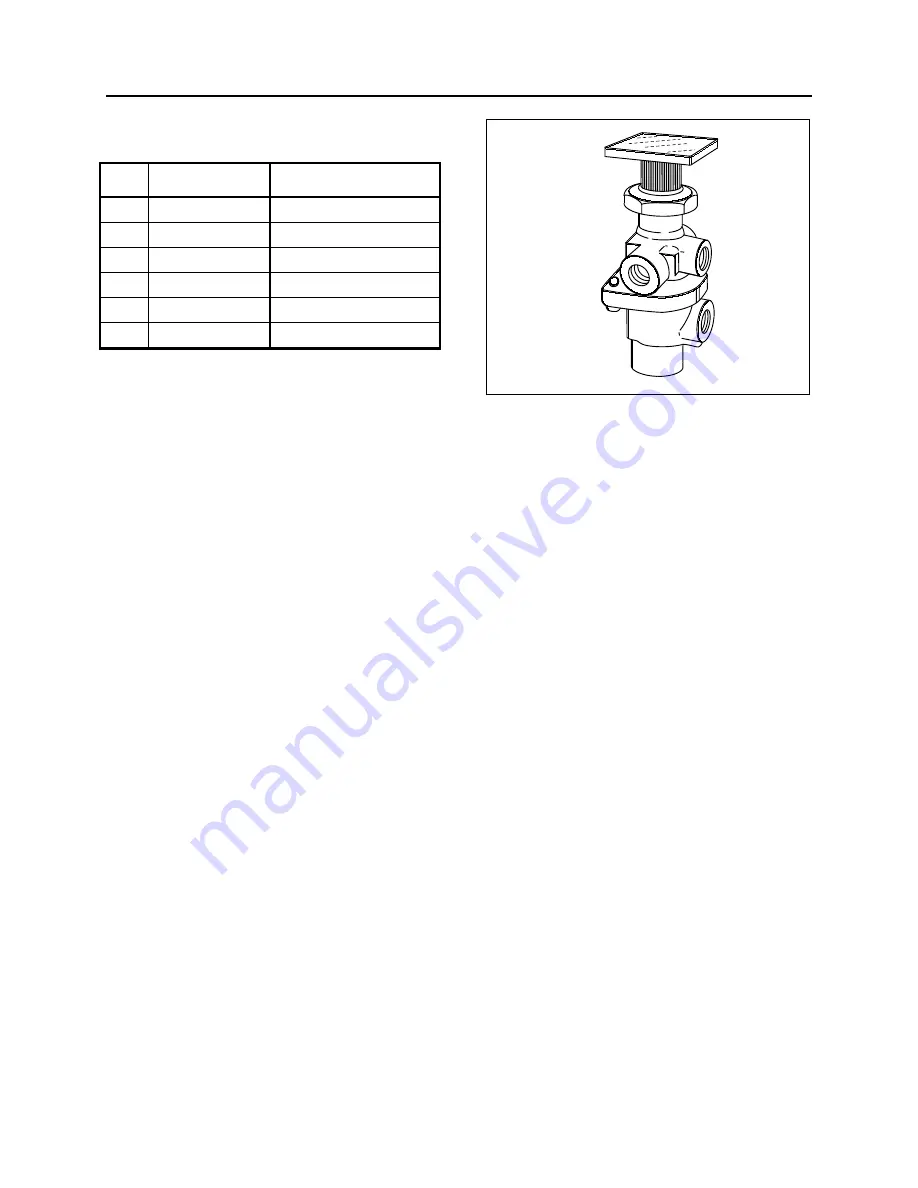

12. EMERGENCY/PARKING BRAKE

CONTROL VALVE (PP-1)

A push-pull control valve mounted on the L.H.

lateral console is provided for parking brake

application or release. The spring brakes are

self-actuated whenever the control valve supply

pressure drops below 60 psi (414 kPa). In the

UP position, brakes are ON. In the DOWN

position, brakes are RELEASED. A protective

case around the knob prevents accidentally

releasing the brakes.

FIGURE 10: PP-1

12142

Maintenance and repair information on this valve

is supplied in the applicable booklet annexed to

this section under reference number

SD-03-3611.

Remove the valve the following way:

1. Drain the air system.

2. Access this valve by tearing out the finishing

panel, which holds the controls in place

(Fig. 10).

3. Disconnect the air tubes.

4. Remove the retaining screws.

5. Service or replace the valve.

6. Installation is the reverse of removal.

13. EMERGENCY / PARKING BRAKES

OVERRULE CONTROL VALVE (RD-3)

A RD-3 control valve is used with the parking

brake overrule system. In the case of self-

application of spring brakes due to a pressure

drop, the brakes can be released by holding

down this control valve. Maintenance and repair

information on this valve is supplied in the

applicable booklet annexed to this section under

reference number SD-03-3611.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...