Section 12: BRAKE AND AIR SYSTEM

Section 12 Updated Sept. 2015

X3-45 Commuter PA1593 DOB 2400-2489

13

FIGURE 19: SR-7

12206

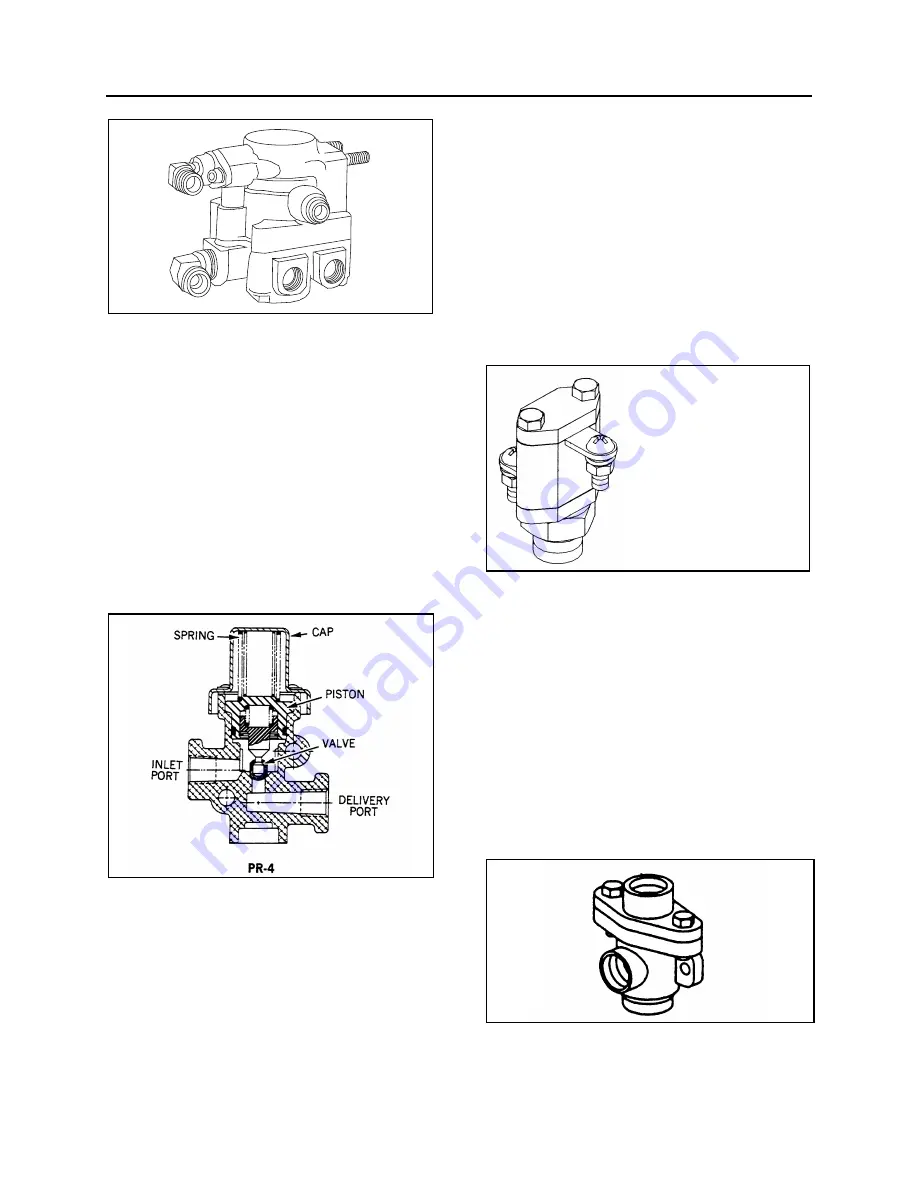

21. PRESSURE PROTECTION VALVE (PR-4)

Maintenance and repair information on the

pressure protection valve is supplied in the

applicable booklet annexed to this section under

reference number SD-03-2010.

The air system includes two pressure protection

valves (Fig. 20). One valve is installed on the

manifold block, and insures at all times a

minimum pressure of 70 psi (482 kPa) in the

suspension air system in the event that a

pressure drop occurs in either the suspension air

system or accessory air system. This valve is

located in the front service compartment beside

the air filter.

FIGURE 20: PR-4

12174

The other valve is installed on the accessory air

tank, and insures a minimum pressure of 70 psi

(482 kPa) in the accessory air system in the

event that a pressure drop occurs in either the

suspension air system or braking air system

(refer to Fig. 1 for accessory air tank location).

22. LOW PRESSURE INDICATOR (LP-3)

Maintenance and repair information on the low

pressure indicators is supplied in the applicable

booklet annexed to this section under reference

number SD-06-1600.

The air system includes two low pressure

switches (Fig. 21), both located on the

pneumatic accessory panel in the front service

compartment. One serves for the parking brake

signal, its pressure setting is 66 ± 6 psi (455 ± 40

kPa). The remaining pressure switch monitors

the parking brake telltale panel indicator; its

pressure setting is 30 psi (205 kPa).

FIGURE 21: LP-3

12214

23. SHUTTLE-TYPE DOUBLE CHECK VALVE

(DC-4)

Maintenance and repair information on the

shuttle-type double check valve is supplied in the

applicable booklet annexed to this section under

reference number SD-03-2202.

The double check valve is located on the

pneumatic accessory panel in the front service

compartment. In the event of a pressure drop in

either the primary or secondary system, this unit

will protect the emergency /parking brake control

valve and the intact portion of the air system

from pressure loss.

FIGURE 22: DC-4

12134

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...