Section 14: STEERING

Section 14 Updated Oct.2014

X3-45 Commuter PA1593 DOB 2400-2489

5

The steering gearbox weighs approximately 100

lbs (45 kg) dry. Exercise caution when handling.

1. Put a container into place, then disconnect

both the inlet and outlet hoses from the power

steering gear. Cover fittings to prevent fluid

contamination.

2. Mark both the pitman arm and sector shaft

with a line, then remove pitman arm. Refer to

"11.1 Pitman Arm Removal"

procedure.

3. Mark both the steering shaft universal joint

yoke and steering gear input shaft with a line,

then disconnect universal joint.

4. Unscrew and remove the power steering

gear.

2.3

POWER STEERING GEAR

INSTALLATION

Reverse

"Power Steering Gear Removal"

procedure paying particular attention to the

following:

1. Tighten fasteners as recommended under

paragraph 14:

‘’Torque Specifications".

2. Bleed air from the system as per step 3, next.

2.4

TROUBLESHOOTING

Perform troubleshooting of the steering gear as

outlined in the

"ZF-SERVOCOM Repair Manual"

,

the

"ZF-SERVOCOM Operating, Servicing

/Maintenance and Inspection Instructions

.

3. BLEEDING POWER STEERING

HYDRAULIC SYSTEM

To bleed the power steering hydraulic system,

refer to the

"ZF-SERVOCOM Repair Manual"

annexed to this section, under heading

"Setting

And Functional Test"

.

4. HYDRAULIC PRESSURE TEST

Perform a pressure test as outlined in the

"ZF-

SERVOCOM Repair Manual"

annexed to this

section under heading

"Setting And Functional

Test"

.

5. POWER STEERING HYDRAULIC PUMP

The power steering pump is a gear driven

hydraulic unit which supplies hydraulic pressure

for the operation of the steering gear. The pump is

mounted on the engine, at the flywheel end and is

also used for driving the fuel pump.

5.1

REMOVAL AND INSTALLATION

The pump is accessible through the engine

compartment R.H. access door.

To remove the pump, proceed as follows:

•

You must first remove the fuel feed pump.

•

Clean around the fuel pump and fuel lines.

Position a container to catch any fuel that

might drain from the pump or lines.

•

Remove the fuel pump.

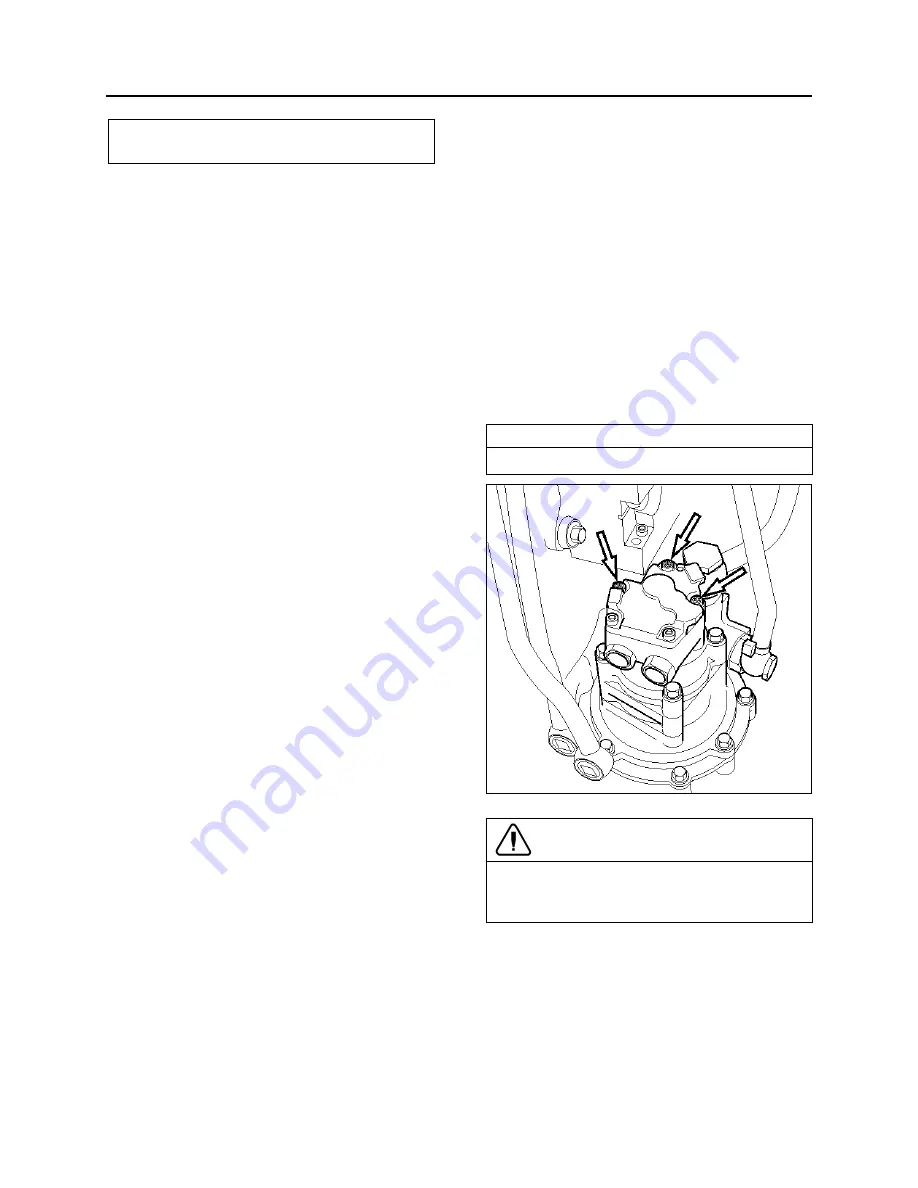

NOTE

Only unfasten the bolts marked with arrows.

FIGURE 4: FUEL PUMP REMOVAL

CAUTION

Ensure to clean around the head of the bolts.

Debris will prevent the tool from fitting properly

and cause damage to the fasteners.

•

Check that the adapter and fuel pump drive

axle are not damaged.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...