Section 16: SUSPENSION

PA1593

17

FIGURE 17: TYPICAL SHOCK ABSORBER SETUP

16009

5. Place the lower and upper mounting pin

stud nuts and torque to 70 - 80 lbf-ft (95 –

110 Nm).

3.3 RADIUS

RODS

Radius rods are used to secure the axles in the

proper transversal and longitudinal positions.

Four radius rods are provided on the drive axle

suspension (three longitudinal and one

transversal) and also four on the tag axle with a

layout similar to the drive axle. Refer to figures

13, 14 and 18 for details. These rods transmit

both braking and driving forces from the axles to

the vehicle body.

3.3.1

Rear Underframe Suspension

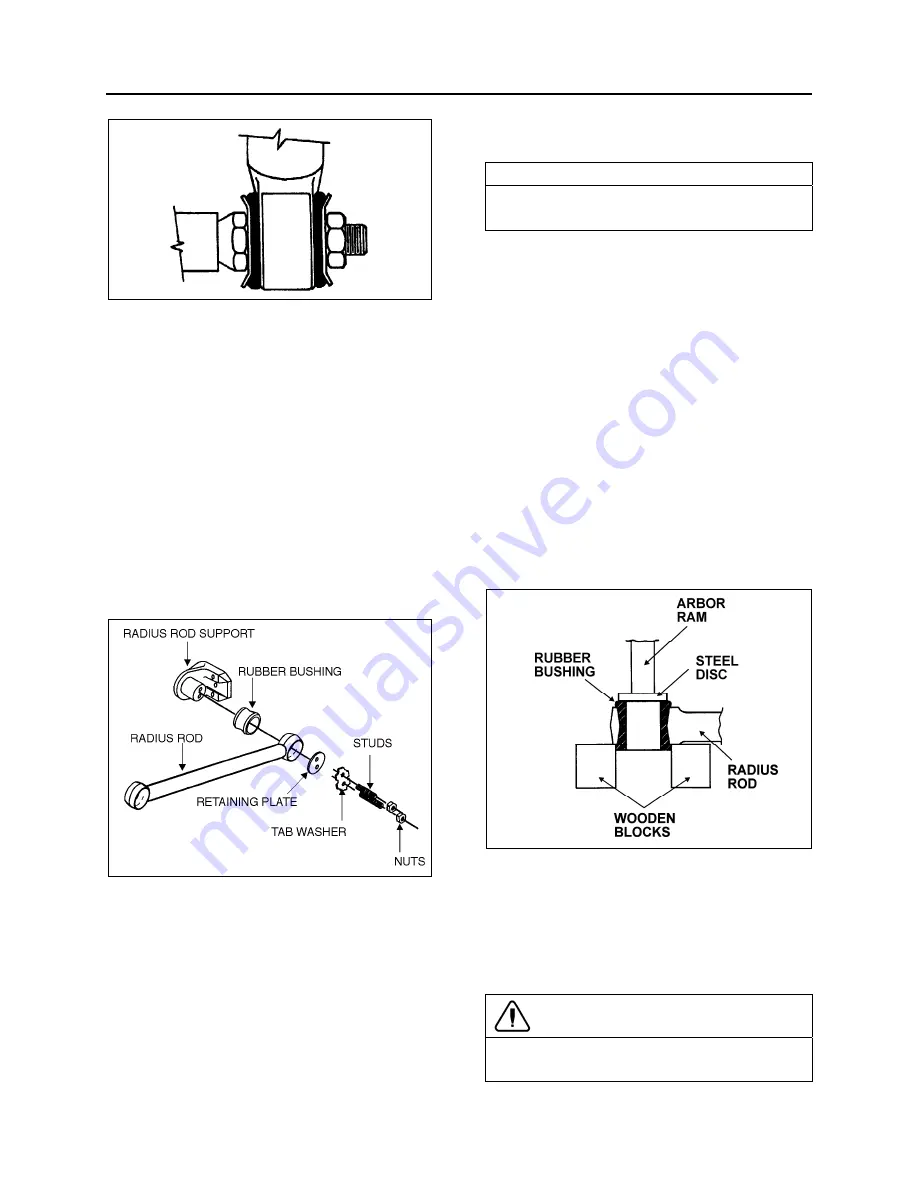

FIGURE 18: TYPICAL RADIUS ROD SETUP

16010

Radius Rod Inspection

The following instructions apply to the radius

rods used on the rear underframe suspension:

1. Clean all parts thoroughly.

2. Inspect radius rods for distortion and cracks.

We recommend the “Magnaflux” process to

detect cracks in the radius rod. Any

damaged part should be replaced with a

new one.

NOTE

New bushings should be used when rods are

replaced.

3. The radius rod bushings should be checked

periodically for signs of shearing,

deterioration, or damage. Any defective part

should be replaced with a new one.

Radius Rod Removal

1. Flatten the tab washer which secures the

two retaining nuts (or bolts), then unscrew

the nuts (or bolts) at each extremity of the

radius rod (Fig. 19).

2. Remove the tab washer and the retaining

plates and radius rod ends from anchor

pins, and then remove the radius rod.

Bushing removal

1. Safely support the radius rod as shown in

figure 19.

FIGURE 19: RADIUS ROD BUSHING REMOVAL

16011

2. Place a flat steel disc, slightly smaller than

the outside diameter of the bushing (Fig.

19).

3. Using an arbor press or a suitable driving

tool, press or drive the old bushing out of the

rod and discard the bushing.

CAUTION

Make sure to prevent the steel disc from

contacting the radius rod end.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...