Section 16: SUSPENSION

PA1593

19

The assembly work may be done only by a

recognized specialized workshop. Ensure that

old and new parts do not get mixed up with each

other. It is for this reason that all the old parts

are to be scrapped immediately after a joint has

been stripped down. A complete repair set must

be used for each joint repaired, i.e. use of only

part of a repair set is not permissible.

Radius Rod Inspection

Take off the load from the ball joint by lifting the

rear of the vehicle. Apply a load on the joint in all

of the degrees of freedom in an axial, radial, etc.

sense with a suitable lever tool. After the load is

taken off, the joint has to spring back into its

starting position. Free play is not acceptable.

Separation of rubber from ball pin or external

joint shell is in accordance with "normal wear

characteristics".

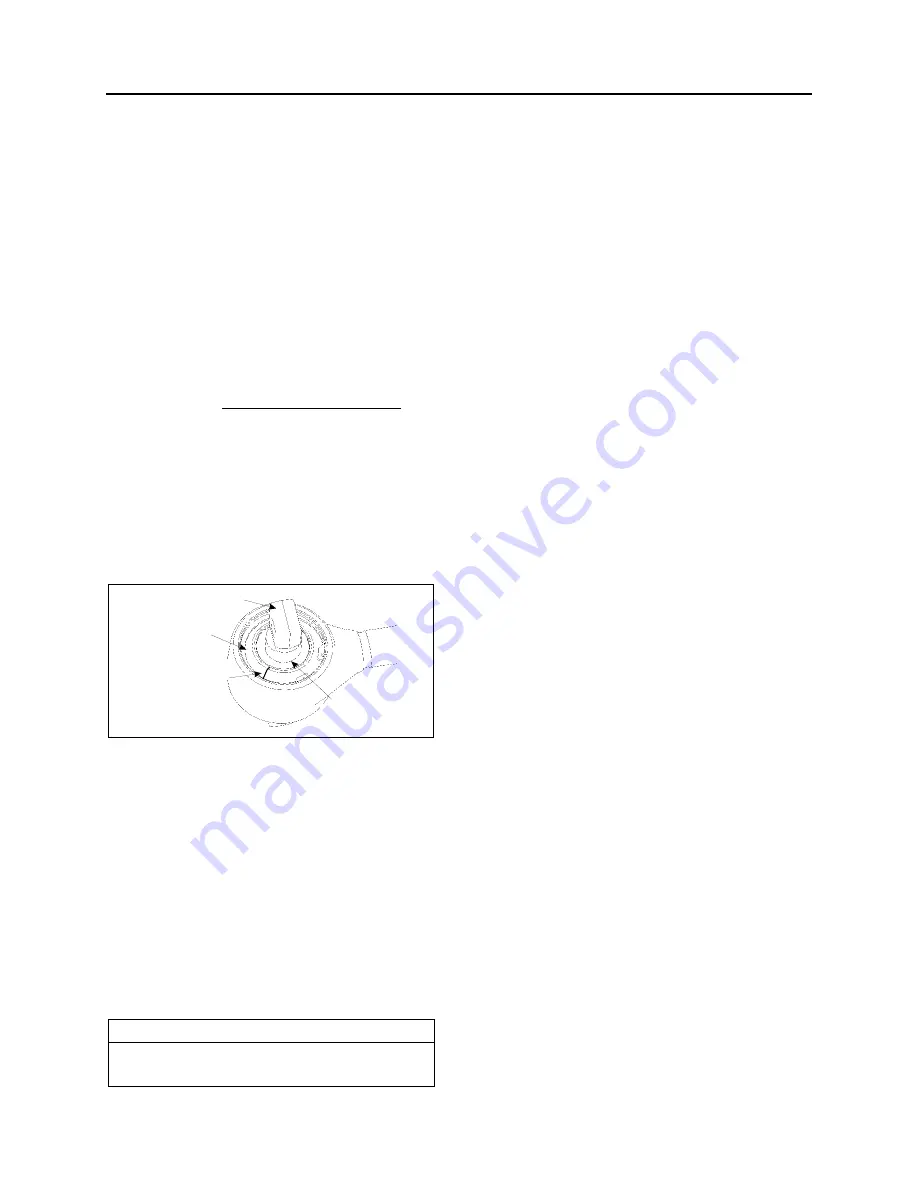

When the following characteristics are noted, the

joint is to be changed:

Free play;

Radial cracking of the external sheet-metal

race.

Ball pin

External joint shell

Radial cracking of the

sheet-metal race

Partial separation

is permitted

FIGURE 23: BALL JOINTS

16173

Stripping Down

Strip down the defective joint through removal of

retaining ring, annular spacer and ball

pin/bushing, assembly and thereafter clean out

housing bore and locking circlips groove.

Radius Rod Assembly

Execute assembly of the new joint parts in the

following sequence:

1. Complete moistening of the contact surface

between housing bore and ball pin through

application of the grease.

NOTE

Apply grease, only in the case of repair kit

(Prevost # 611114)).

2. Insert ball pin/bushing, assembly. In case of

the two-bolt type, ensure that the bolt bores

are in the correct position in relation to the

axis of the tube.

3. Place joint in receiving fixture and mount

annular assembly tool on the housing. Then

locate annular spacer and retaining ring in

the housing using axial load with the aid of

assembly matrix. If the ends of the annular

spacer are not in contact with each other,

the thus formed opening must be located at

180

to the opening of the retaining ring. Pay

attention during assembly to ensure that the

retaining ring eyelets are located at each

side of the housing shaft axis (retaining ring

eyelet lug points to tube), and that retaining

ring is properly engaged in the groove of the

housing.

When repairing defective ball pin assemblies,

the necked down-bolt must regularly be replaced

with a new one.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...