Section 16: SUSPENSION

PA1593

21

4. SUSPENSION HEIGHT ADJUSTMENT

The flow of pressurized air from the accessory

air tank to the air springs is controlled by three

height control valves. The two rear valves are

mounted to the subframe and connected to the

rear axles through an arm and link connection.

The front valve is mounted to the subframe and

connected to the front air tank support. These

connections allow the valves to apportion air

pressure in the springs to the vehicle load,

maintaining normal ride height.

Immediate response height control valves

increase or decrease the air pressure in the

suspension system as required. One height

control valve is located

at center of front sway

bar

, and regulates air to front suspension air

springs in order to maintain the vehicle at the

required height. Two are located at the drive

axle, one on each inner side of rear

wheelhousing.

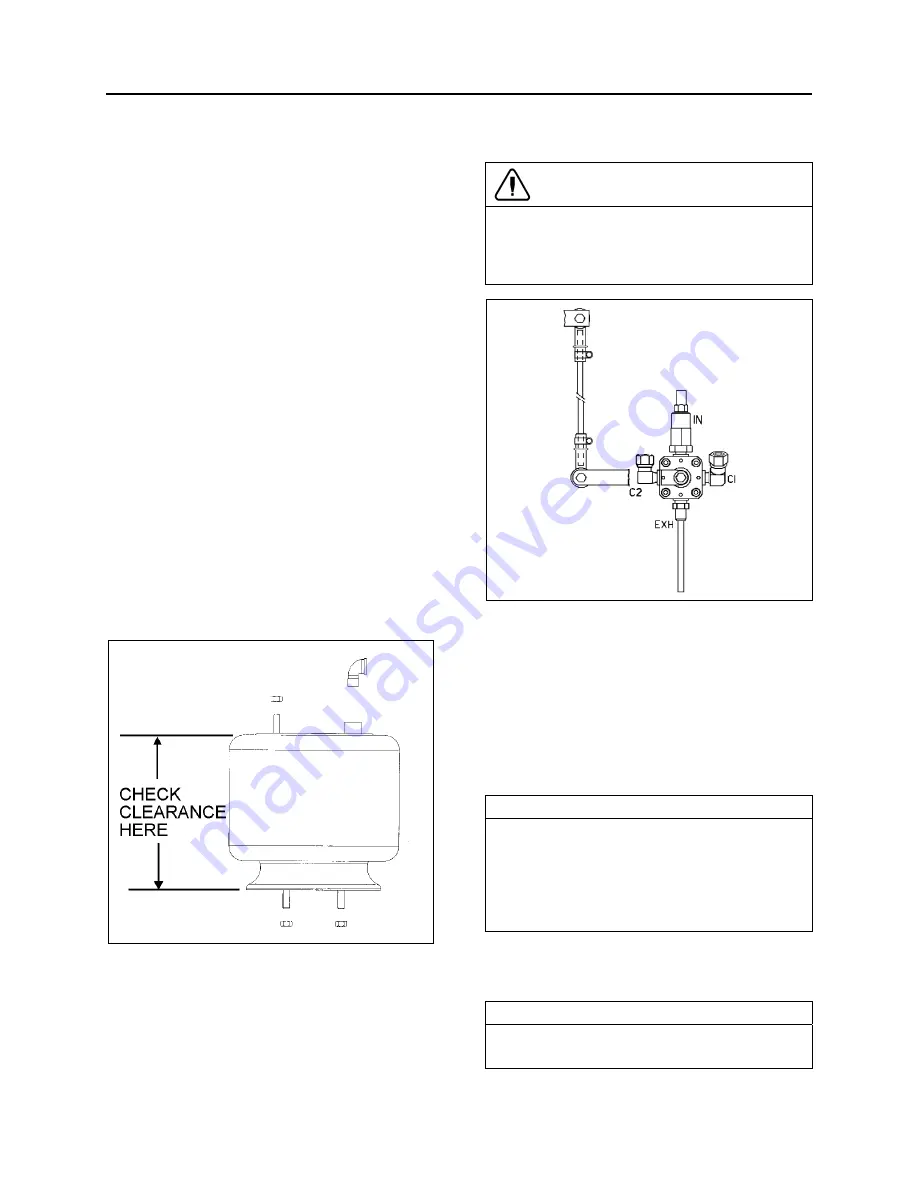

The appropriate vehicle body height is obtained

by measuring the clearance of all the air springs

installed on the vehicle. The two front air springs

clearance should be 11 ± ¼“ (279 ± 6 mm).

Refer to figure 24 to identify the correct area to

take measurement. The rear air springs

clearance should be 11 ½ ± ¼" (292 ± 6 mm).

FIGURE 24: TYPICAL AIR SPRING CLEARANCE

16058

At this point, it should not be necessary to make

an adjustment under normal service conditions.

However, if an adjustment is required, change

the position of the overtravel lever in relation to

the overtravel control body. The lever should be

moved up to raise vehicle height, and down to

lower it. Check that main air pressure is at

normal operating pressure and raise the vehicle

to the specified height.

CAUTION

Always adjust on "fill cycle". If it is necessary

to lower vehicle height, release sufficient air to

be well below height, and adjust to height or

fill cycle.

FIGURE 25: FRONT HEIGHT CONTROL VALVE

16100

The normal ride height is obtained by adjusting

air spring clearance of both front and rear

suspension as follows:

Front air spring clearance

1. With the vehicle at normal operating air

pressure [100 - 125 psi (689 - 860 kPa)],

measure air spring clearance. This

clearance should be 11 ± ¼“ (279 ± 6 mm).

NOTE

The measurement should be taken from

underneath the upper air spring support on

subframe to top of the lower air spring support

on axle (refer to figure 24 for more details). If

adjustment is required, begin with the drive

axle.

2. Loosen the clamp on the height control

valve rubber coupling and bring it up or

down (Fig. 25).

NOTE

Allow suspension to stabilize before taking

reading.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...