Section 16: SUSPENSION

PA1593

22

When the desired height is obtained, tighten

clamp.

Rear air spring clearance

1. With the vehicle at normal operating air

pressure [100 - 125 psi (689 - 860 kPa)],

measure air spring clearance. This

clearance should be 11 ½ ± ¼" (292 ± 6

mm).

NOTE

The measurement should be taken from

underneath the upper air spring support on

subframe to top of the lower air spring support

on axle (refer to figure 24 for more details).

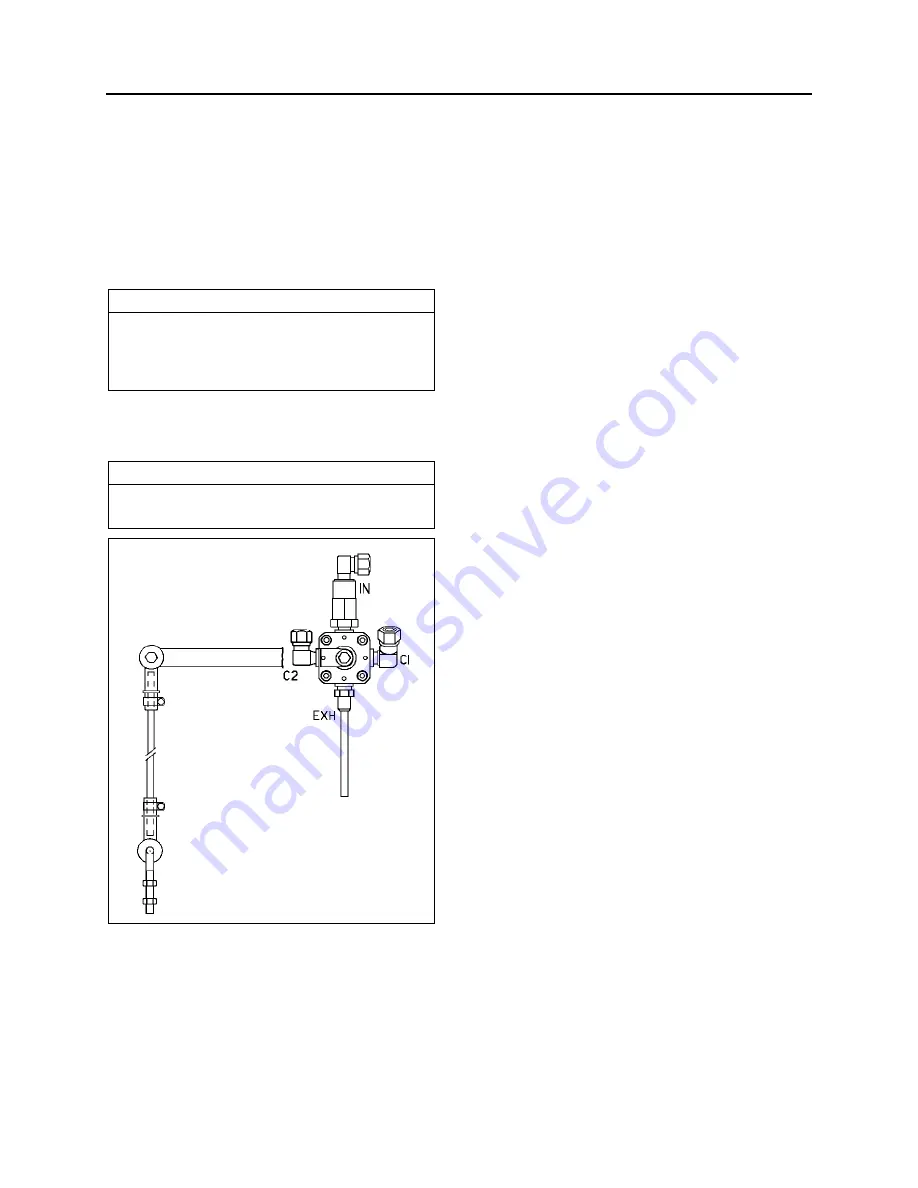

2. Loosen the clamp on the height control

valve rubber coupling and bring it up or

down (Fig. 26).

NOTE

Allow suspension to stabilize before taking

reading.

FIGURE 26: REAR HEIGHT CONTROL VALVE

16093

When the desired height is obtained, tighten

clamp.

5. HEIGHT CONTROL VALVE

The height control valves automatically add air

to, or release air from air springs to maintain

constant suspension height regardless of load,

or load distribution. Each valve adjusts

independently according to the following

conditions:

Loading Position

As the load increases and lowers the vehicle

body, the overtravel lever commands the height

control valve to add air to air springs.

Neutral Position

When vehicle body reaches the normal ride

height, the height control valve overtravel lever

reaches the "neutral" position and keeps both

the supply and exhaust ports closed to ensure

normal ride height is maintained. This condition

remains static until the vehicle load is altered.

Unloading Position

As the load decreases and raises the vehicle

body, the overtravel lever commands the height

control valve to release air from air springs.

5.1 MAINTENANCE

The height control valve requires no periodic

maintenance. Height control valve linkage

operates on rubber bushings and no lubrication

should be attempted at this location. Inspect the

valve for loose joints, air leaks and worn

bushings.

5.2 REMOVAL AND INSTALLATION

Before disconnecting a height control valve air

line, securely support the vehicle by its jacking

points on the body, and place safety supports

underneath body. Refer to paragraph

"16.

Vehicle Jacking Points"

in Section 18,

"Body"

.

1. Exhaust air from air system by opening all

air tank drain cocks. Remove height control

valves.

2. Disconnect overtravel lever from link and

pull down lever to exhaust remaining air

from air springs.

3. Disconnect air supply and delivery lines

from the height control valve. Cover line

ends with tape to prevent entry of foreign

matter.

4. Remove the nuts retaining the height control

valve to the mounting bracket, then remove

valve assembly.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...