Section 18: BODY

PA1593

19

Spray filler and rubber seal groove

generously with soapy water.

Using the special filler insertion tool, insert

the filler into the rubber seal groove.

Gradually insert filler into the rubber seal

groove ensuring to leave a 2 inch excess

length at the filler extremity.

Every 6 inches or so, it is important to

compress the filler due to its tendency to

contract during drying process.

When filler insertion is almost complete,

cut filler leaving ¼” of excess length to

thwart filler contraction over time then

insert filler into groove.

FIGURE 15: APPLICATION 0F SIKA 221 BLACK

Reinstall center post and interior finishing

panels.

Clean windshield surface of butyl residue.

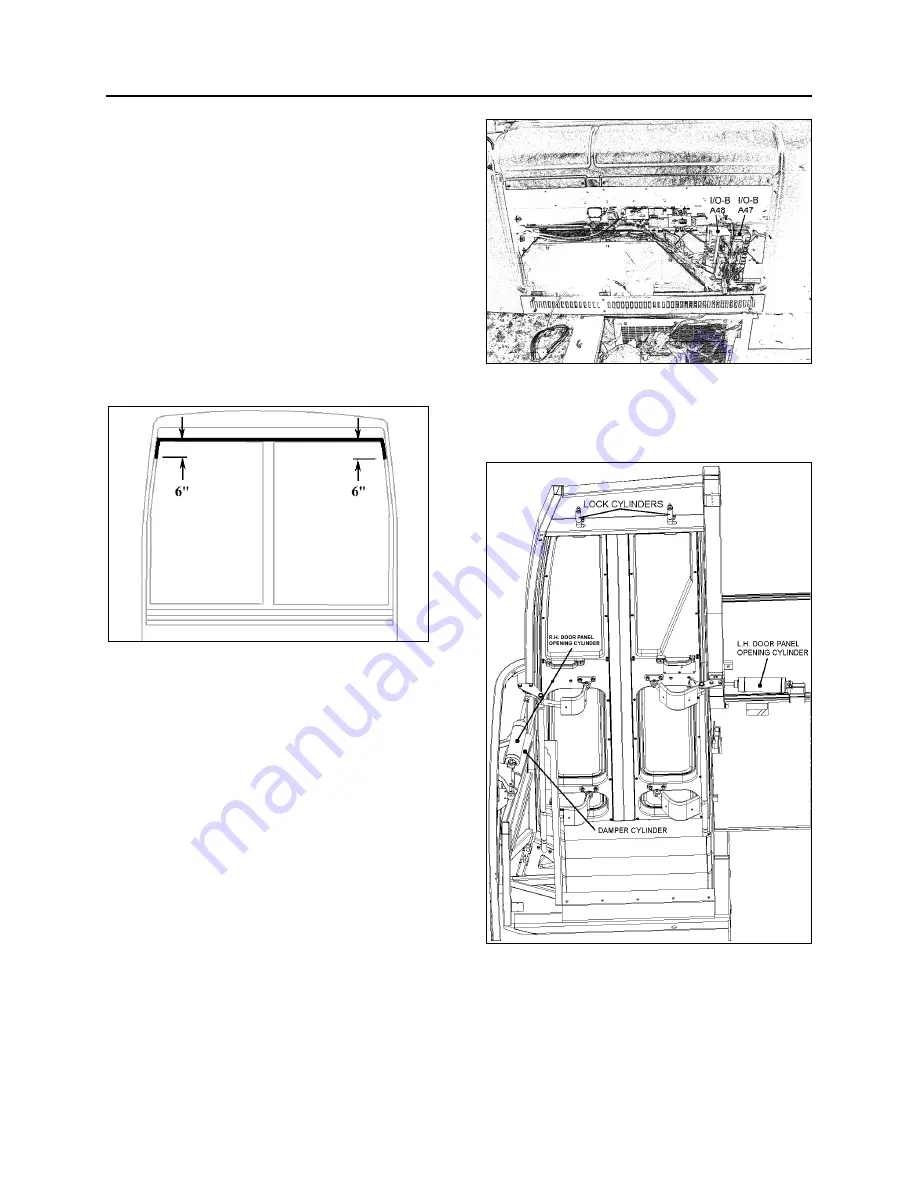

6.1.6 Bi-Fold Entrance Door

An air operated “bi-fold type” entrance door, with

an air door cylinder and damper assembly

installed under the right hand dash for the R.H.

door panel opening. Another air door cylinder is

installed behind the wall to the right of the first

curb-side passengers’ seat for the L.H. door

panel opening. The opening and closing door

speed cycle is adjustable by a damper mounted

in parallel with the R.H. door panel cylinder on

the door hinge. Door activation is controlled by a

panel (Fig. 16), located near the defroster and

wiper motors. The accessory air reservoir

supplies air to this system.

FIGURE 16: ENTRANCE DOOR & WIPER CONTROL

PANEL

06619

The door is held in the closed position during

coach operation by a two air cylinder locking

mechanisms (Fig. 17).

FIGURE 17: ENTRANCE DOOR - VIEW FROM INSIDE

Air cylinders with return spring in the cylinder

body are used. Air cylinders are controlled by an

electrically operated solenoid valve energized by

a multiplex module located under the right hand

dashboard.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...