Section 18: BODY

PA1593

24

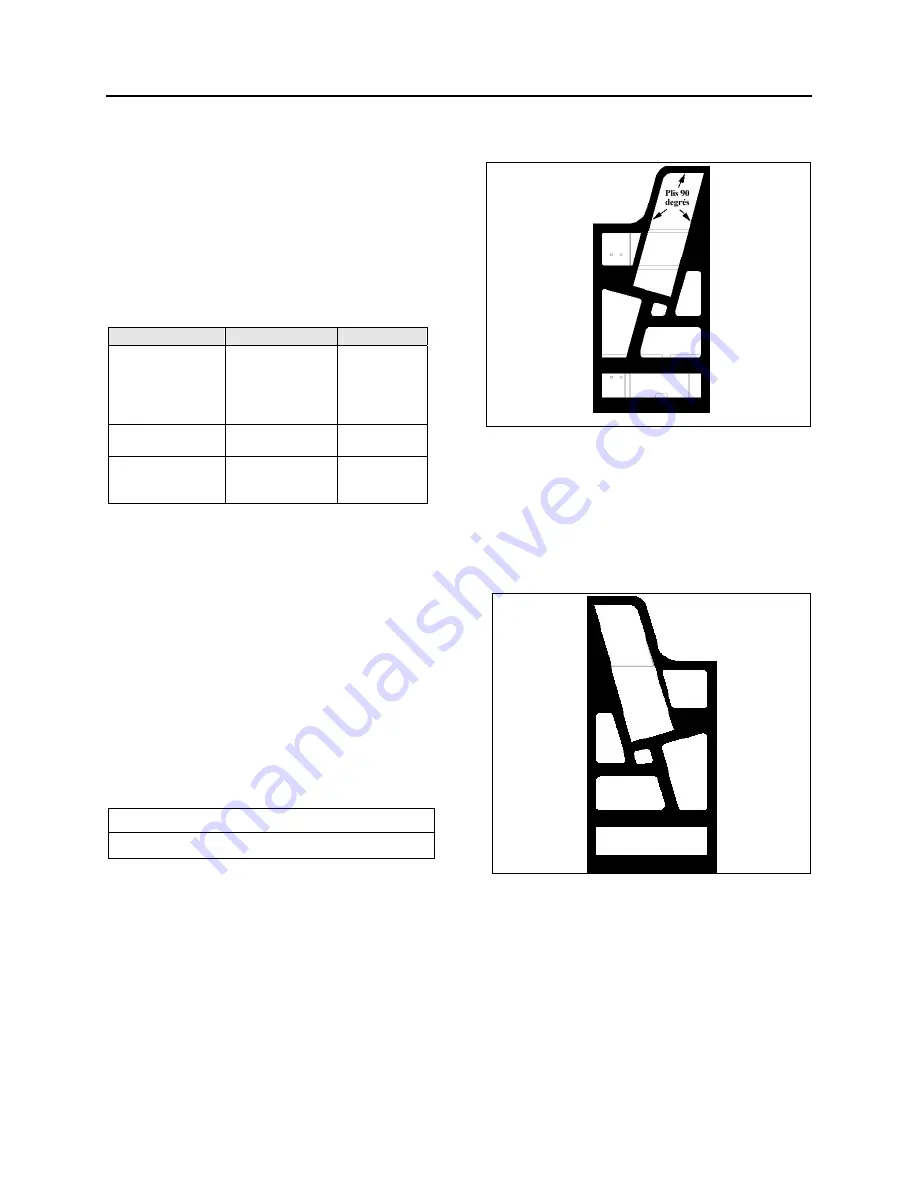

5. Peel of protective paper from the seal.

Position the seal flush with the top, sides

and lower edges of the door.

6. Progress slowly all around the door.

7. Cut the seal and glue both ends with

LOCTITE 414 glue.

8. To assure bonding, press a small roller on

top of the new seal.

Lubrication

Part

Lubricant

Frequency

Latches

Upper door catch

Door cylinder rod

end with bearing

grease fitting

Low temperature

grease

Every six

months

Door locking

mechanism

White grease

Every six

months

Key hole

Damper pins

Hinges

Low viscosity oil

Every six

months

Body Panel and Window

For the removal of front electrical & service

compartment door body panel, you will need:

Pneumatic “Zip gun” type tool;

Razor sharp window scraper;

Open service door.

Remove interior finishing panels to access

rub rail fixing bolts, then remove rub rail.

Remove windshield washer reservoir,

door lock and power window connector.

Using the “

Zip Gun

”, cut Sika bead

located ¼ inch (7-8 mm) from each body

panel edge.

NOTE

Wear ear plugs during this operation.

Separate body panel from door.

Using a razor sharp window scraper,

remove from door frame Sika bead and

double-face self adhesive tape residue.

Clean door frame using anti-silicone.

Using a scratch pad “Scotch Brite”,

scratch the perimeter of the door frame

where the adhesive will be applied.

Clean door frame again using anti-

silicone.

Apply some Sika 206 G+P onto door

frame.

Prepare new body panel using a scratch

pad “Scotch Brite”.

Use a tack cloth to remove any dust or

residue from the body panel surface.

Clean body panel using anti-silicone.

Apply some Sika 206 G+P onto body

panel.

Apply an even coat of Sika 255 onto the

door frame.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...