Section 18: BODY

PA1593

63

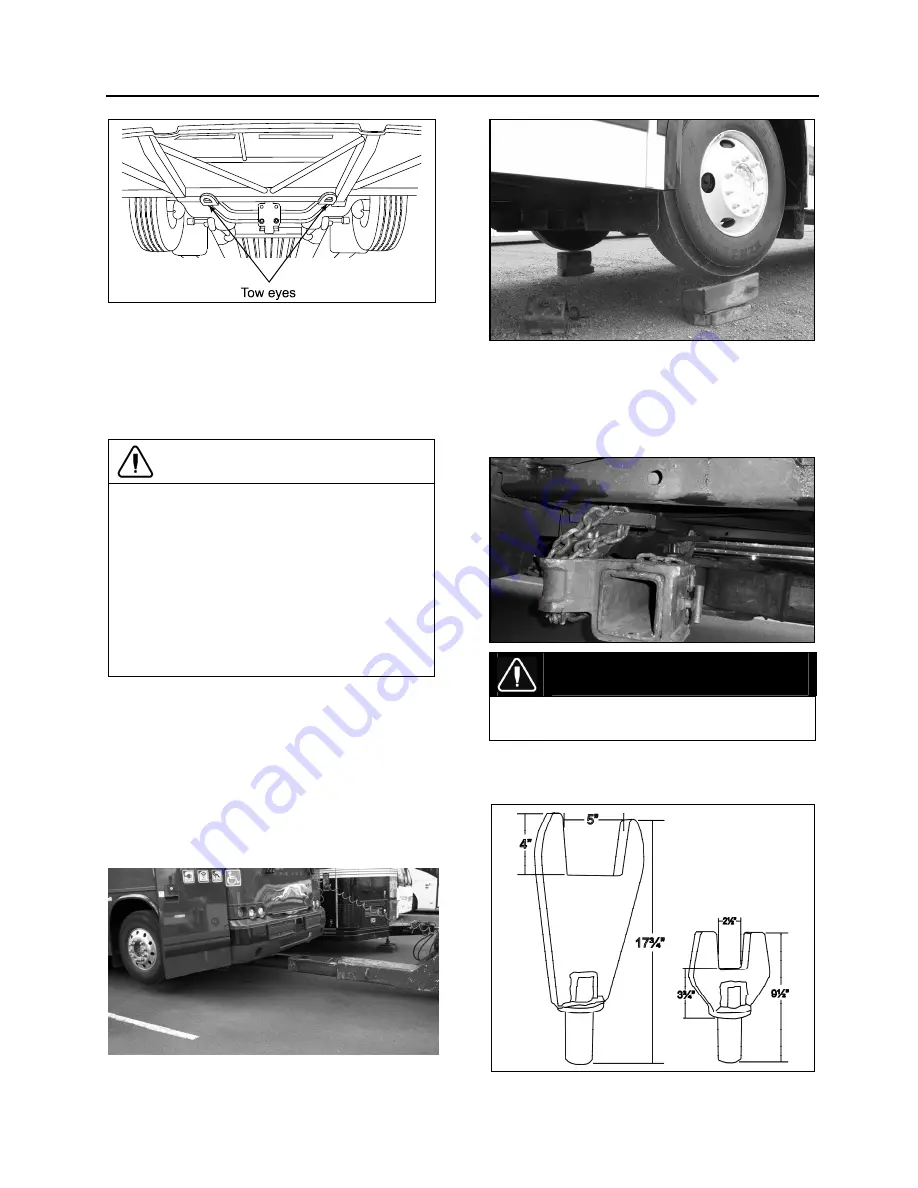

FIGURE 55: TOW EYES UNDER VEHICLE

18401

Disconnect driveshaft or remove both drive

axle shafts to prevent damage to the trans-

mission. Plug axle tube to prevent oil loss.

Refer to Rockwell's

"Maintenance manual

no.5"

annexed at the end of Section 11: Rear

Axle of the maintenance manual.

CAUTION

To prevent damage to the drive train

components, disconnect axle shafts or

driveshaft before towing. Do not attempt to

push or pull-start a vehicle equipped with an

automatic transmission.

Failure to disconnect the driveshaft,

remove the drive axle shafts or lift the drive

wheels off the ground before towing can

cause serious transmission damage and

void the warranty.

The towed vehicle must be lifted from under

the front end only. The tow truck must be

equipped with the proper lifting equipment to

reach under the tow eyes or the front axle

since no other lifting points are recommend-

ed. Lifting and towing from any other point are

unauthorized as it may cause serious dam-

age to the structure. Do not unload or raise

the tag axle when lifting and towing to prevent

overloading the drive axle.

Raise the front of the coach then install

wooden blocks underneath front tires.

Install axle forks and supports onto tow bar,

position axle forks around beam and into tow

eyes, insert chains into tow eyes to secure.

DANGER

Do not carry passengers while the coach is

being towed.

The coach can also be towed by installing

axle forks on the front axle.

FIGURE 56: AXLE FORKS

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...