Section 01: ENGINE

PA1593

12

FIGURE 9: COOLER POSITION DURING ENGINE

CRADLE INSERTION OR REMOVAL

6. From underneath, unfasten the bolts fixing

the engine cradle.

7. Disconnect the engine coolant hose near

the starter.

8. Disconnect air compressor suction and

discharge hoses.

With Vehicle Lowered

Lower the vehicle enough to access all

components.

Engine Compartment R.H. side

Disconnect cables from two chassis

grounds located on diagonal member.

Inside engine compartment, disconnect

starter, alternators and heater cables.

Also disconnect AFSS cable if

applicable.

Disconnect from engine, connector

C398 and vehicle interface harness

connector located above EECU

connectors. Also disconnect DPF cable.

Disconnect power steering pump hoses.

Shut off fuel line shut-off valve.

Close engine fuel supply shut-off valve

on primary fuel filter. Disconnect the fuel

line located above fuel filters and

connected to inlet port.

Disconnect fuel return line located

above fuel filters.

Disconnect alternators cooling duct and

put aside.

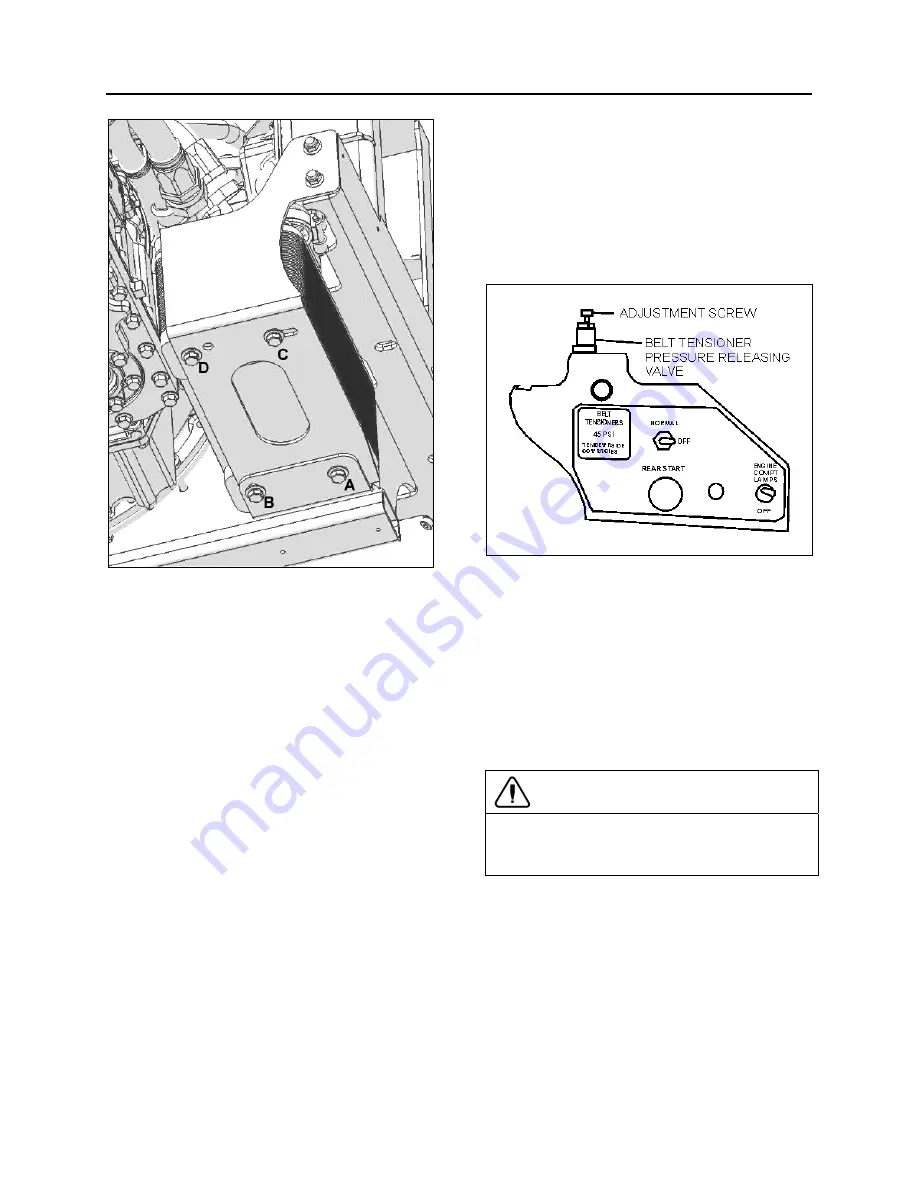

FIGURE 10: BELT TENSIONER VALVE

12200

Locate the A/C compressor belt

tensioner pressure releasing valve

(Fig. 10). Turn pressure releasing valve

handle counterclockwise in order to

release pressure in belt-tensioner air

bellows and loosen belts. Remove the

belts.

Disconnect and remove the engine-air

intake duct mounted between air

cleaner housing and turbocharger inlet.

CAUTION

To avoid damage to turbocharger, cover the

turbocharger inlet opening to prevent foreign

material from entering.

Disconnect and remove the exhaust

pipe mounted between the flexible

coupling and the pipe going to the

Diesel Oxidation Catalyst (DOC) and

Diesel Particulate Filter (DPF)

assembly. If necessary, refer to Section

4: EXHAUST SYSTEM under

“EXHAUST AFTERTREATMENT

SYSTEM OVERVIEW".

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...