Section 22: HEATING AND AIR CONDITIONING

PA1593

7

The condenser coil mounted on the opposite

side of the evaporator is ventilated by four axial

fans. The fan motors are protected by a

manually-resettable 70 amp circuit breaker

(CB7) mounted on the rear junction panel and

accessible from the engine compartment curb-

side door.

FIGURE 8: CONDENSER COMPARTMENT

22299

Furthermore, the following relays, diodes and

multiplex module are located in the evaporator

compartment (Fig. 9). They are mounted in the

HVAC junction box located inside the evaporator

compartment door.

FIGURE 9: A/C JUNCTION BOX

A/C Junction Box

Multiplex Module

A54 I/O-B

Relays

R10

Condenser Fan Sp. 2

R12 Evaporator

Fan

R20

Water Pump Relay

Diodes

D9 HVAC

D11

Pass. Liq. Sol.

D17

Lugg. 5

th

Compt

D19 Lugg.

2

nd

Compt

D20

Lugg. 1

st

Compt

D25 Evap.

Fan

D30

Water

Pump

D73 Opt.

D80

Opt.

4. HVAC UNIT MAINTENANCE

No special maintenance is required on the

passengers and driver's HVAC units, with the

exception of cleaning their respective coils and air

filters, plus periodic inspection for broken drains,

hoses and charging of system.

MAINTENANCE

Squeeze rubber discharge tubes located

underneath the appropriate compartment to

eliminate the accumulated water and dirt

every three months.

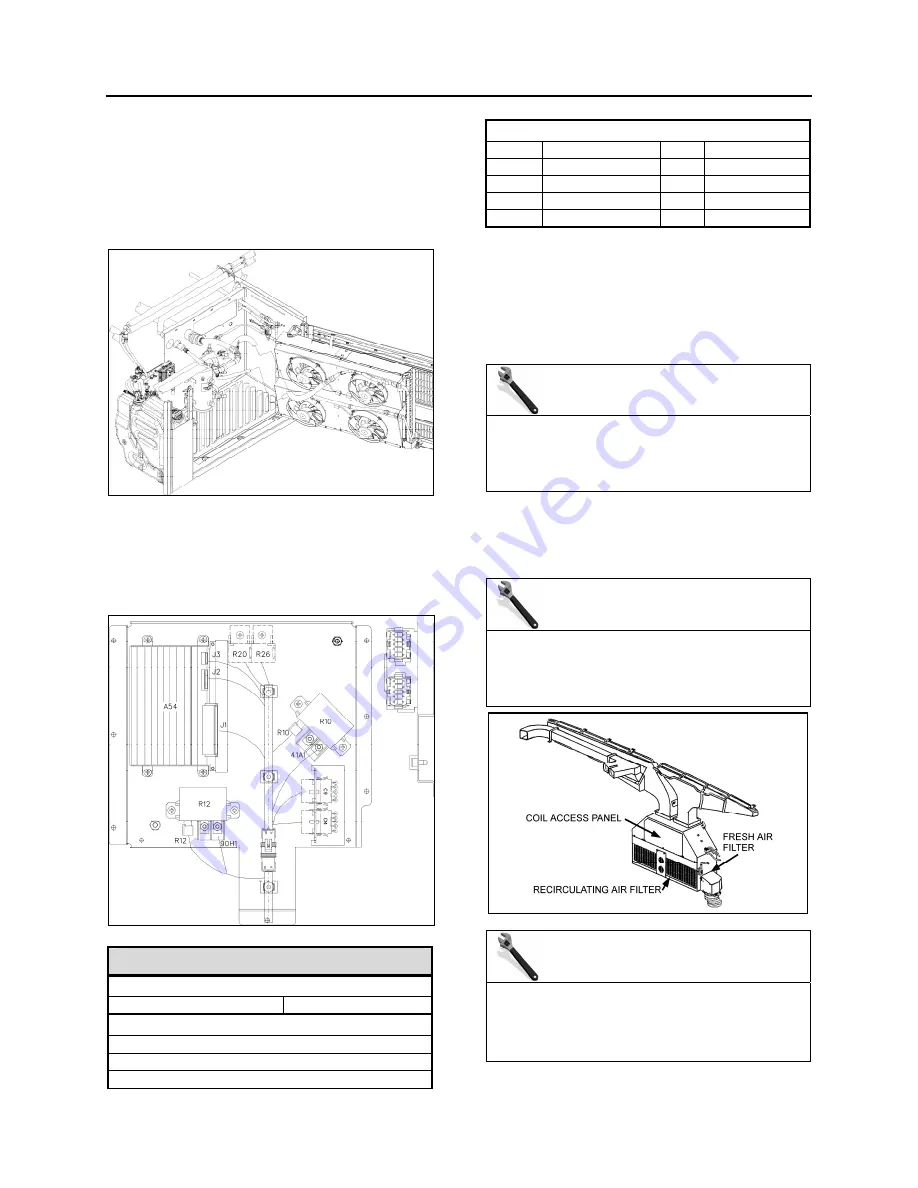

4.1 COIL CLEANING

Check the external surface of the coil at regular

intervals for dirt or any foreign matter.

MAINTENANCE

For the driver's HVAC unit, remove the grill

and the access panels and back flush the coil

every 12,500 miles (20 000 km) or once a year,

whichever comes first

FIGURE 10: DRIVER'S HVAC UNIT COIL ACCESS PANEL

MAINTENANCE

For the passengers’ section evaporator coil,

remove the access panel and back flush the

coil every 12,500 miles (20 000 km) or once a

year, whichever comes first

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...