Section 22: HEATING AND AIR CONDITIONING

PA1593

20

2. Remove the failed compressor and repair it if

possible.

3. Install new or repaired compressor.

4. Change the filter dryer.

5. Circulate clean R-134a or nitrogen using a

pressurized metal cylinder or a reclaiming

machine to clean out many of the

contaminants collected in the coil valves,

TXV (Thermal Expansion Valve), solenoid

valves, check valves, and any other

mechanical component that may have

collected contaminants.

6. Evacuate and charge the system normally.

7. Run the unit for 8 hours and monitor the

pressure drop across the filter dryer. Also

check the liquid line dryer for signs of

restriction. If the pressure drop across the

filter dryer exceeds 12 to 14 psig (82,75 to

96,5 kPa) with a 40°F (5°C) evaporator coil

temperature, stop the unit and change the

liquid line and suction line filter dryer. After 4

or 5 hours of operation, stop the unit and

replace the filter dryer.

8. After 8 hours of operation, stop the unit and

remove a sample of the compressor oil and

check its color, odor, and acidity, using

instructions supplied above. If the oil is

contaminated, replace the oil and repeat step

7. If the oil is not contaminated, change the

filter dryer again and replace the moisture-

liquid indicator.

9. After approximately 7 days of operation,

recheck the compressor oil for cleanliness

and acidity.

7. CENTRAL A/C SYSTEM COMPONENTS

7.1 COMPRESSOR (CENTRAL SYSTEM)

7.1.1 Belt

Replacement

DANGER

Set the battery master switch to the “Off”

position. For greater safety, set the engine

starter selector switch in engine compartment

to the “Off” position.

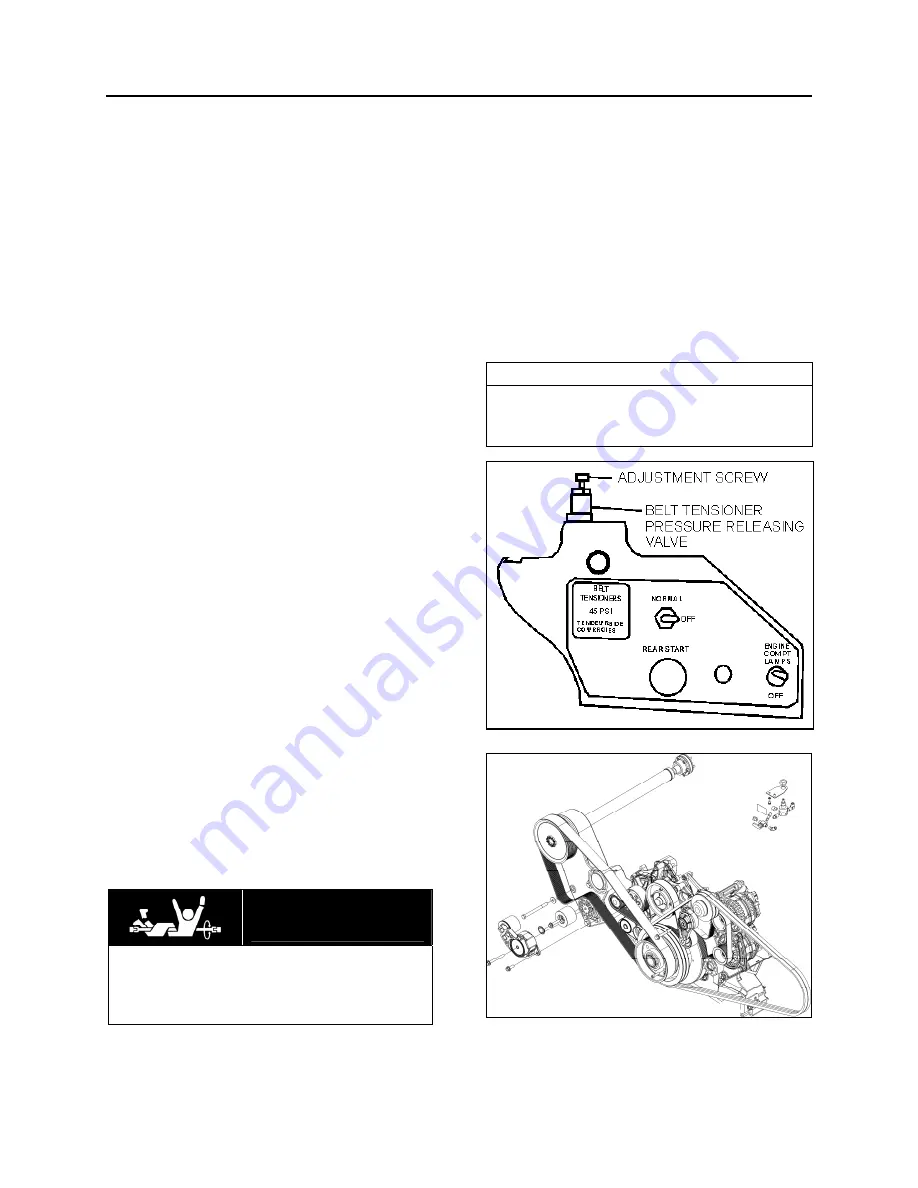

1. Open engine compartment rear doors and

locate the belt tensioner pressure releasing

valve (Fig. 20), mounted above the engine

R.H. side door next to the air pressure

regulator, then turn handle clockwise in

order to release pressure and tension on

belts.

2. Remove the radiator fan driving mechanism

belt (Refer to Section 05: Cooling).

3. Slip the old A/C compressor belts off and

the new ones on.

4. Reset belt tensioner pressure releasing

valve (Fig. 20) to 45 psi (310 kPa) to apply

tension on the new belts as explained in

Section 12.

NOTE

Both belts must always be replaced

simultaneously to ensure an equal distribution

of load on each of them.

FIGURE 20: AIR PRESSURE REGULATOR

FIGURE 21: BELT ARRANGEMENT

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...