Section 22: HEATING AND AIR CONDITIONING

PA1593

21

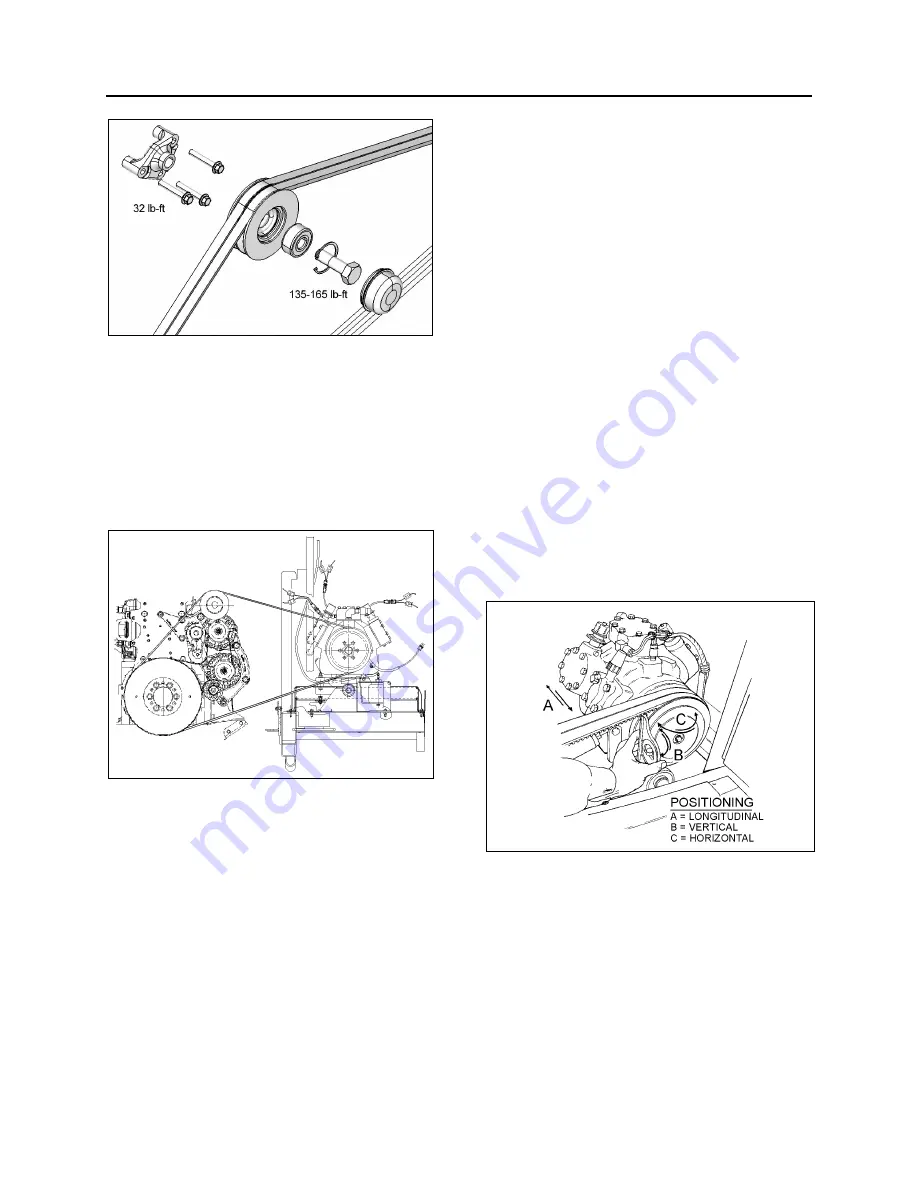

FIGURE 22: IDLER PULLEY INSTALLATION ON VOLVO

D13 ENGINE

7.1.2 Belt Tension Adjustment

Belt tensioning is applied through air bellows

which are adjusted by an air pressure regulating

valve. The correct pressure of 45 psi (310 kPa)

is set at the factory. Periodically verify the

pressure at the regulating valve using a

pressure gauge and correct if necessary.

FIGURE 23: A/C COMPRESSOR BELT ADJUSTMENT

22288

7.1.3 Pulley

Alignment

In order to avoid skipping, disengagement and a

premature wear of compressor belt, it is

necessary to align compressor pulley with the

crankshaft pulley. Before performing the

following procedure, release air from belt

tensioner bellows by means of the air pressure

releasing valve. After completing these

procedures reset belt tensioner air pressure

regulator to 45 psi (310 kPa).

7.1.4 Longitudinal Compressor Alignment

1. Rest an extremity of a straight edge of

approximately 46 inches (117 cm) against

the upper part of the outer face of crankshaft

pulley, positioning the other end close to the

compressor clutch pulley (Figs. 24 & 25).

2. Check the distance between each extremity

of straight edge (1. Fig. 25) and the first

drive belt. If they are different, loosen the

compressor support bolts and with a

hammer, knock support to slide it in order to

obtain the same distance; then tighten bolts.

7.1.5 Horizontal Compressor Alignment

1. Rest an extremity of the straight edge

against the upper part of the outer face of

compressor pulley, positioning the other end

close to the crankshaft pulley.

2. Check the distance between each extremity

of straight edge (1, Fig. 25) and drive belt. If

they are different, loosen the pillow block

compressor bolts and with a hammer, knock

compressor pillow block to slide it, in order

to obtain the same distance; then tighten

bolts.

FIGURE 24: COMPRESSOR ALIGNMENT

22072

7.1.6 Vertical Compressor Alignment

Rest a short "angle and level indicator" on the

outer side face of the crankshaft pulley, adjust

the level indicator inclination at 0

o

and check if

the compressor pulley is at same angle (Fig.

24). If it is not the same, shim under the

appropriate pillow block in order to obtain the

correct angle.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...