Section 22: HEATING AND AIR CONDITIONING

PA1593

24

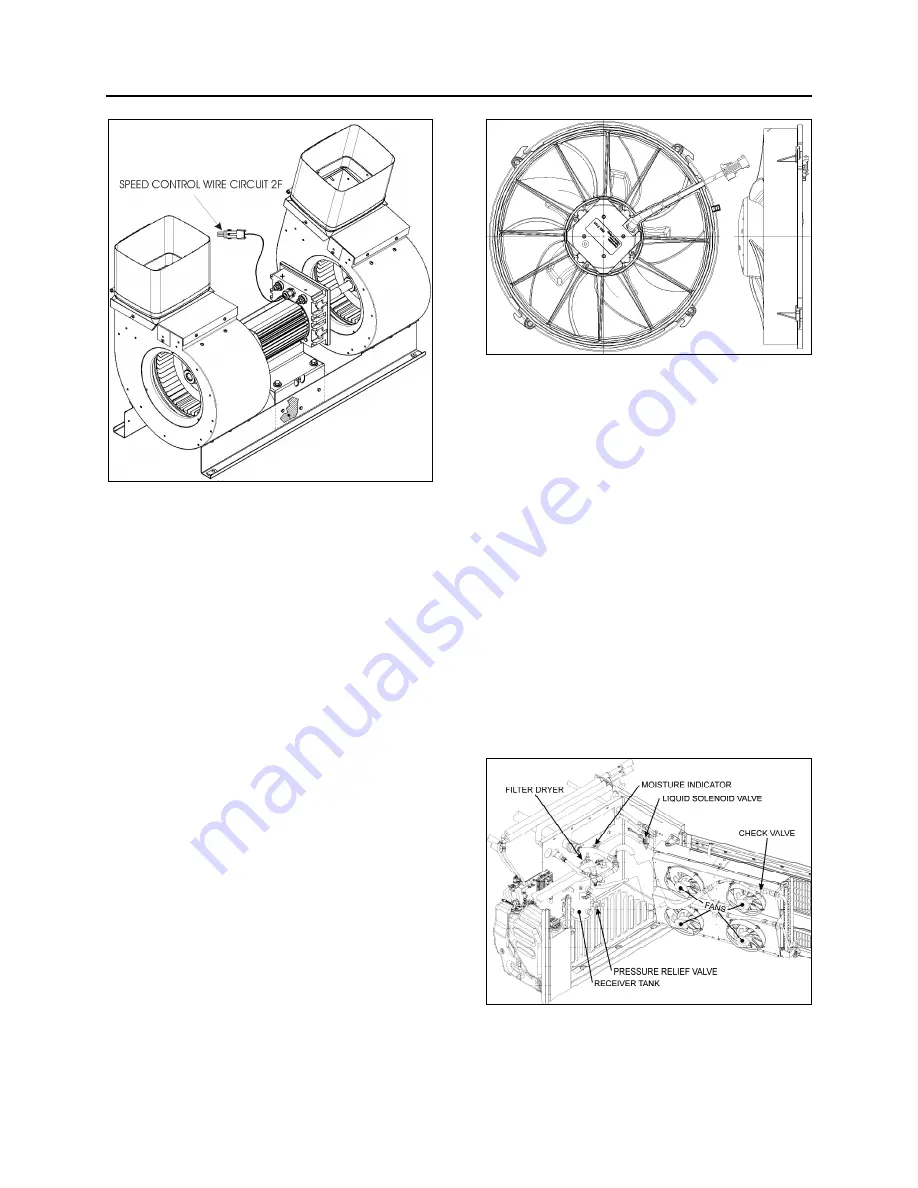

FIGURE 28: EVAPORATOR MOTOR ASSEMBLY

7.4 CONDENSER

The central A/C system condenser coil is hinge

mounted on the R.H. side of the vehicle on the

A/C condenser door (Fig. 30). Since

condenser’s purpose is to dissipate heat from

the hot refrigerant, it is important to keep the

cooling coils and fins clean. A clogged coil will

cause high discharge pressure and insufficient

cooling.

7.4.1 Condenser Fan Motors

Four brushless fan motors (Fig. 29), 28.5 V -

(0.6 HP - 0.42 kW) are installed in the

condenser compartment on R.H. side of vehicle

in order to ventilate the condenser coil. They are

mounted on a support, fastened to the door. The

fans pull outside air through the condenser coil

and discharge it through an opening at bottom of

compartment. When temperature drops inside

condenser, the pressure in the refrigerant line

also drops and it is, therefore, no longer

required to cool condenser. Consequently, when

pressure drops to 130 psi, the motors will run at

low speed and if the pressure continues to drop

to 90 psi, a pressure switch stops the motors so

that fans do not operate needlessly. When

pressure rises to 120 psi, the pressure switch

reactivates the motors. If the pressure rises to

170 psi, the motors will switch to high speed.

For details about electrical wiring, refer to

“A/C

and Heat system”

in the master wiring diagram.

FIGURE 29: CONDENSER FAN MOTOR

22322

7.4.2 Condenser Fan Motor Removal

1. Set the battery master switch to the

“Off”

position.

2. Disconnect wiring from terminals on motor.

Tag each wire to aid in identification at time

of reconnection.

3. Remove the four hexagonal head cap

screws retaining the fan motor assembly to

the mounting support.

4. Remove the motor.

7.5 RECEIVER

TANK

The receiver tank is located in the condenser

compartment (Fig. 30). The function of the

receiver tank is to store the liquid refrigerant.

During normal operation, the level of the

refrigerant should be approximately at the mid-

point of the lower sight glass.

FIGURE 30: A/C CONDENSER COMPARTMENT

22323

In case of extreme pressure there will be a rise

in the liquid receiver tank. A pressure relief valve

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...