Section 22: HEATING AND AIR CONDITIONING

PA1593

31

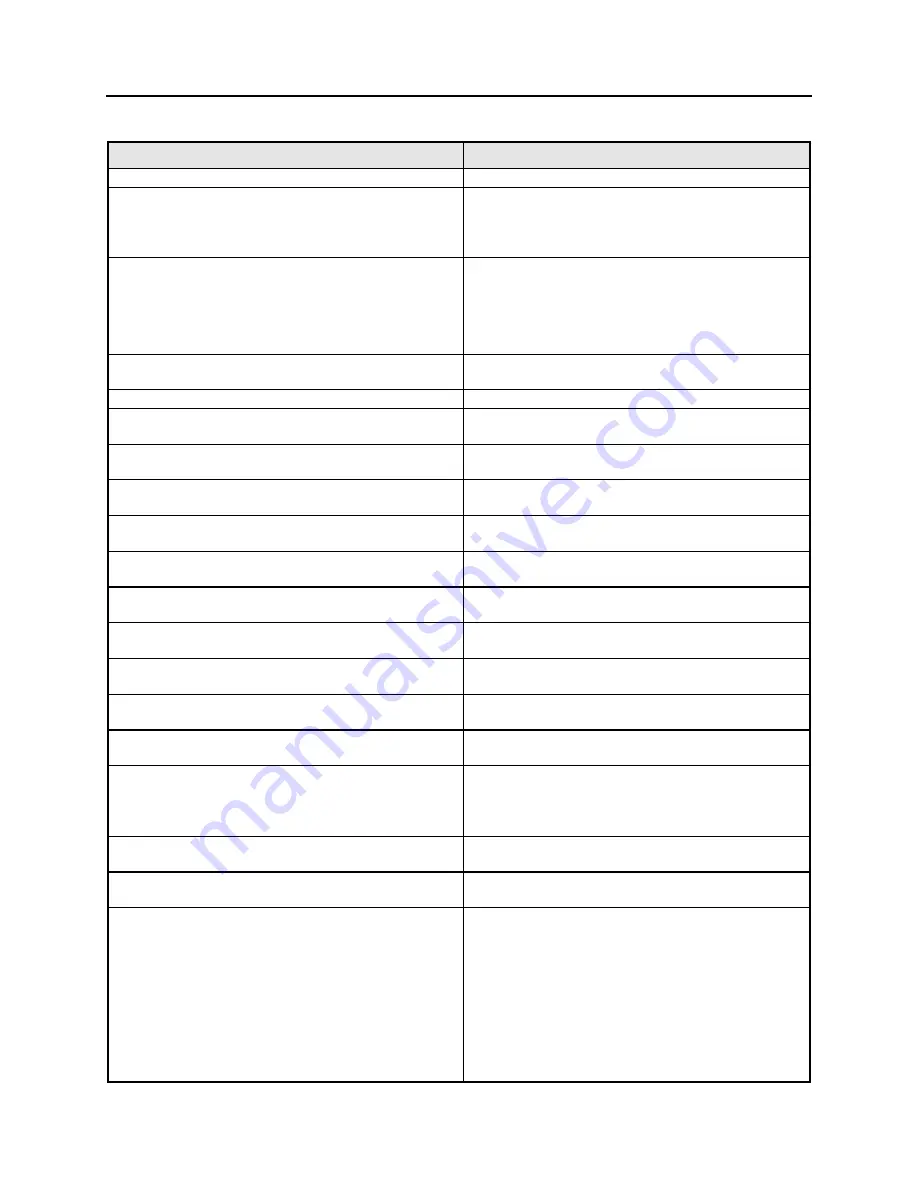

7.10.2 A/C

TROUBLE

CAUSE

Low suction pressure and frosting at dryer outlet.

Clogged filter.

Low Oil Level.

Check for oil leaks and for leaking oil seal. Do not

attempt to check oil level unless system has been

stabilized at least 20 minutes. See oil level

verification.

Excessively cold suction line.

Loss of contact between the expansion valve

bulb and the suction line or sticking of the

expansion valve.

Check for foreign matter and clean, repair or

replace the valve.

Excessively cold suction line and noisy

compressor.

Check superheat adjustment. Check remote bulb

contact. Check expansion valve for sticking.

Compressor squeaks or squeals when running.

Check oil level. Replace oil seal.

Noisy or knocking compressor.

Check for broken internal parts. Overhaul if

required.

Compressor vibrates.

Check and tighten compressor mounting bolts

and belt tension.

Low refrigerant level

Check for refrigerant leaks and add refrigerant if

required.

Suction pressure rises faster than 5 pounds per

minute after shutdown.

Check compressor valve for breakage or

damage.

Insufficient cooling.

Check for refrigerant leaks. Check condition of air

filter and motors.

Insufficient air flow.

Dirty or iced evaporator. Dirty air filter. Blowers

inactive. Clogged ducts.

No flow of refrigerant through expansion valve.

Filter dryer is clogged. Remote bulb has lost

charge or expansion valve is defective.

Expansion valve hisses. Bubbles in moisture and

liquid indicator.

Gas in liquid line. Add refrigerant.

Loss of capacity

Clogged filter. Obstructed or defective expansion

valve.

Superheat too high.

Reset superheat adjustment. Check for clogged

external equalizer line, or filter dryer.

Reduced air flow:

a. Dirty or clogged air filter;

b. Evaporator motor inoperative; or

c. Plugged return air ducts.

Dirty or iced evaporator coil. Clean or replace air

filter. Check return ducts for obstructions. Check

blower motor.

Frequent starting and stopping on low pressure

control switch.

Lack of refrigerant. Check for leaks. Recharge.

Compressor intermittently starts and stops.

Intermittent contact in electrical control circuit.

Compressor valves not in operating position.

Non-condensable in the refrigeration system.

Leak on system, system in vacuum in low temp.

Specific symptom, pressure in system will not

correspond to ambient temperature on shutdown.

Only non-condensable will cause this.

(Example: Pressure of idle R-134a system in

80°F (26.6°C) room should be 86.4 psi (595.7

kPa). See temperature chart in this section.)

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...