Section 22: HEATING AND AIR CONDITIONING

PA1593

37

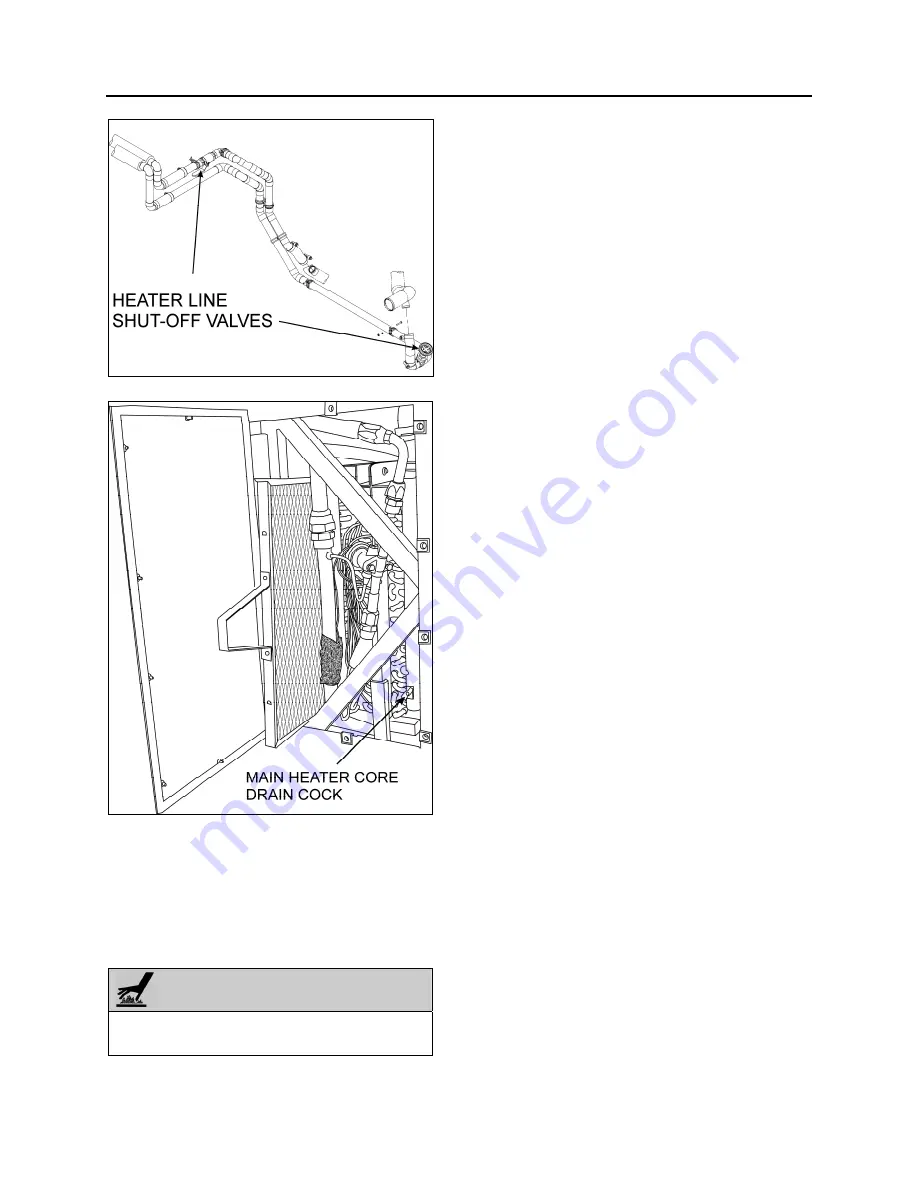

FIGURE 39: HEATER LINE SHUT-OFF VALVES

FIGURE 40: EVAPORATOR COMPARTMENT

3. The main heater core drain cock is located

in the evaporator compartment. To access

the valve on X3-45 coaches, open baggage

compartment door located in front of the

evaporator compartment (L.H. side). Open

access panel by turning the three screws of

panel ¼ of a turn.

WARNING

Before proceeding with the following steps,

check that coolant has cooled down.

4. Open drain cock in bottom of heater core,

you can unfasten a hose connection on top

of heater core (Fig.40) in order to allow air

to enter while draining.

8.2

FILLING HEATING SYSTEM

1. Ensure that the drain hose is reconnected

and the manual vent and drain cock are

closed.

2. Open the surge tank filler cap and slowly fill

the system to level of filler neck.

3. After initial filling, the water shut-off valves

should be open and the water recirculating

pump should be energized to assist in

circulating coolant through the heating

system. To perform this operation, start the

engine, switch on the HVAC control unit,

both driver and passengers’ sections, and

set temperature to the maximum position in

order to request the heating mode in each

of these sections.

4. When coolant level drops below the surge

tank filler neck, slowly fill the system to level

of filler neck.

5. Once the level has been stabilized, replace

cap.

8.3

BLEEDING HEATING SYSTEM

Whenever the heating system has been drained

and refilled, or the system has run low on

coolant and coolant has been added, it is

necessary to bleed air from heating system.

Locate the manual vent illustrated in Figure 38,

and open momentarily until no air escapes from

the line.

8.4 SOLDERING

Before soldering any part of the system, make

sure the area is well ventilated. Use (stay clean)

flux sparingly and apply solder (95-5 round wire

1/8 inch). After completing repairs, test for leaks.

When using heat at or near a valve, wrap with

water saturated rag to prevent overheating of

vital parts.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...