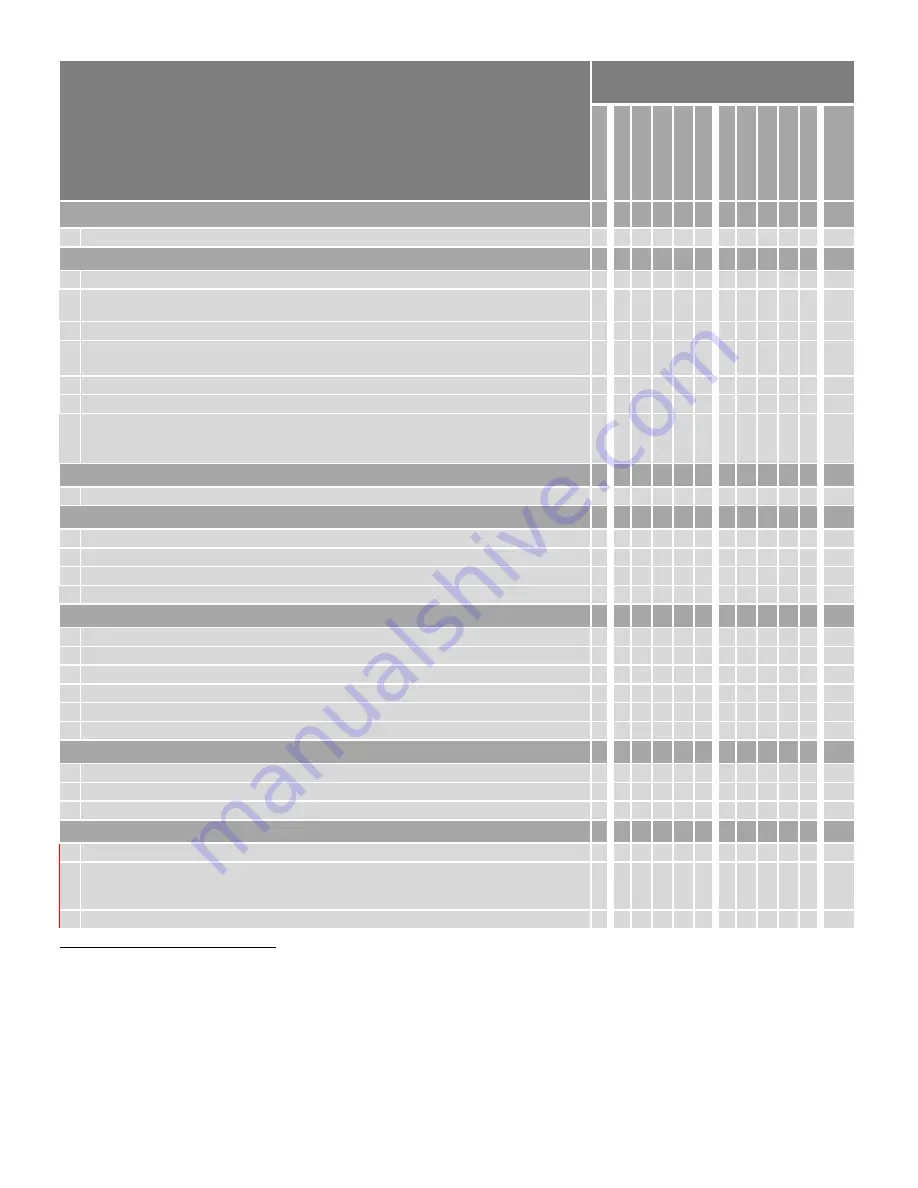

Section 24

X3-45 Commuter PA1593 Maintenance Manual DOB 2400-2489

Schedule revised 11/11/2015

LUBRICATION AND SERVICING SCHEDULE

NYCT X3-45 Commuter DOB 2400-2489

Proceed to maintenance operation

every (miles)

Item

6 000

12 00

0

18 00

0

24 00

0

30 00

0

50 00

0

100 0

00

150 0

00

200 0

00

250 0

00

Lubr

icant

GENERAL

1 Flexible hoses - thoroughly inspect all hoses

01 ENGINE

1 Engine oil & filter - heavy operation condition, change

17

A

2 Drive belts and idlers – visually inspect for signs of deterioration, cracks or frayed

material

3 Drive belts - change

4 Air cleaner - replace filter element when indicated by restriction indicator or according

to this interval whichever comes first

27

5 Valves & injectors - initial adjust

6 Valves & injectors - check & adjust

7 Automatic belt tensioners & idler pulleys inspection – Remove belts, check for noisy

bearings, play, bushing play. Perform “

AUTOMATIC BELT TENSIONER AND IDLER PULLEYS

INSPECTION

” procedure

03 FUEL

1 Primary & secondary fuel filters - change at every engine oil change

28

04 EXHAUST AND AFTERTREATMENT SYSTEM

1 DEF tank - drain & clean with water, clean filler neck strainer

2 DPF filter - either clean or replace at

66 000 miles

1

3 DEF pump filter element – first change at 100 000 miles then according to chart

4 Diffuser assembly, rain cap & drain tube – check proper functioning, clean

05 COOLING

1 Coolant surge tank - test coolant solution

21

2 Coolant filter - change (Fleet Charge Fully Formulated Coolant)

18

3 Radiator fan gearbox - check oil level

20

G

4 Radiator - inspect exterior core & clean with low pressure water jet if necessary

5 Radiator fan gearbox - change oil

20

G

6 Cooling system - drain, flush & refill (Fleet Charge 50/50 Fully Formulated Coolant)

21

C

06 ELECTRICAL

1 HD10 Bosch alternators drive belt - replace

2 HD10 Bosch alternators brushes - check & replace brushes if necessary

3 Battery terminals - clean & coat terminals

30

07 TRANSMISSION

2

1

Filled with TES389 approved fluid

-

change transmission fluid, Main & Lube filter

16

I

2

Severe vocation filled with TranSynd or TES295 synthetic fluid only, no

mixture

3

& using High-Capacity filters

4

.

Transmission fluid

- change every

84 000 miles

16

H

3

Severe vocation filled with TranSynd or TES295 synthetic fluid only, no mixture

16

H

1

Based on 71347mi on average before 4500hrs at Yukon depot and 55782mi on average before 4500hrs at Ulmer depot. Median value=63565mi,

increased to 66000mi to fit with 6000mi interval based schedule.

2

Allison Transmission recommends that customers use fluid analysis as the primary method for determining fluid change intervals. In the absence of a

fluid analysis program, the fluid change interval listed in the chart above should be used. Change filters according to the Table 1 & Table 2 even if a

fluid analysis shows that the fluid doesn’t need to be changed.

3

When the transmission contains a mixture of fluids (defined as the quantity of non-TranSynd or non-TES 295 fluid remaining in the transmission after

a fluid change combined with the quantity of TranSynd or TES295 required to fill the transmission to the proper level), perform the fluid & filter change

according to the TES389 intervals.

4

Extended TranSynd or TES 295 fluid & filter change intervals are only allowed with Allison High-Capacity filters.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...