Section 24

X3-45 Commuter PA1593 Maintenance Manual DOB 2400-2489

Schedule revised 11/11/2015

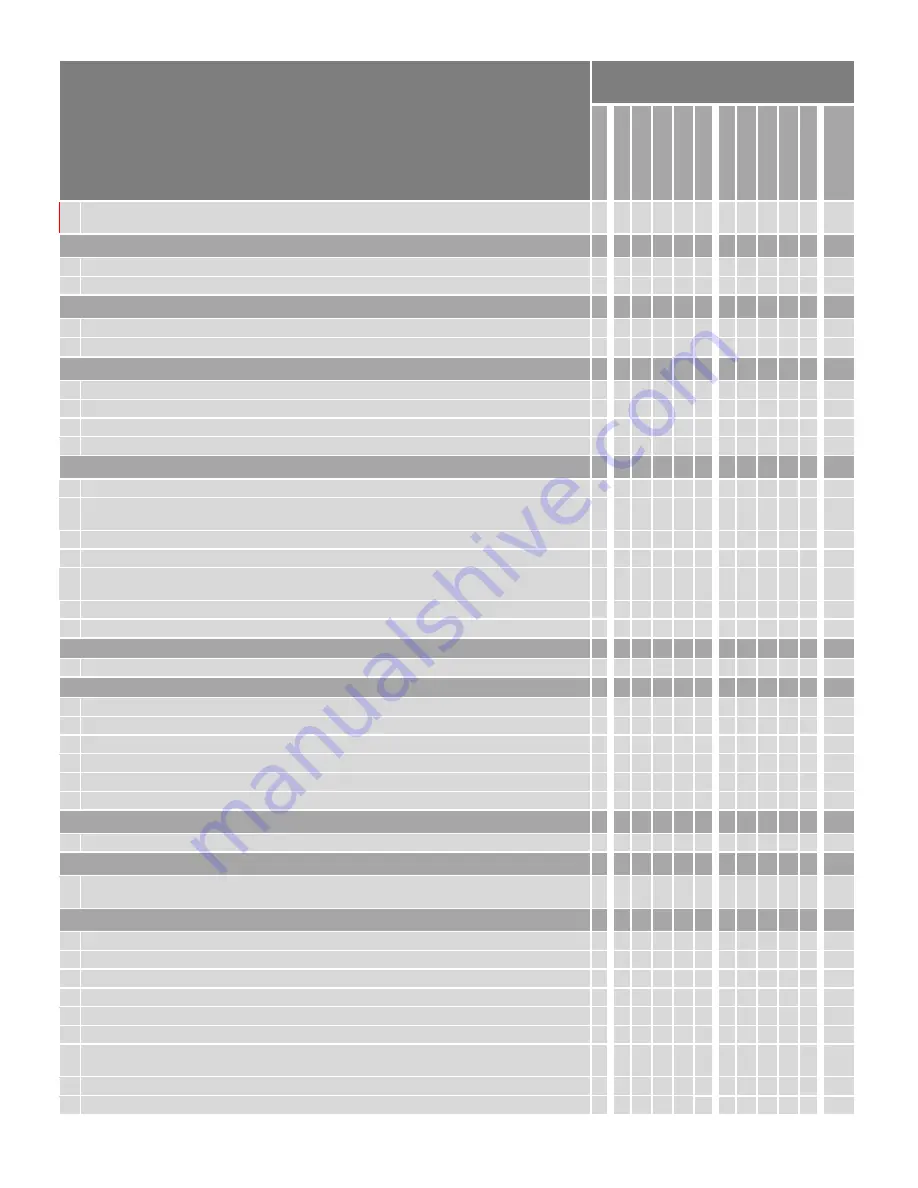

LUBRICATION AND SERVICING SCHEDULE

NYCT X3-45 Commuter DOB 2400-2489

Proceed to maintenance operation

every (miles)

Item

6 000

12 00

0

18 00

0

24 00

0

30 00

0

50 00

0

100 0

00

150 0

00

200 0

00

250 0

00

Lubr

icant

& using High–Capacity filters

. Transmission Main & Lube filters – change every

42 000 miles

09 PROPELLER SHAFT

1 Perform Spicer’s Driveshaft Assembly Inspection Procedures

34

2 Grease one fitting on each universal joint

34

K

10 FRONT AXLE

1 Steering knuckle (king) pins - grease two fittings per knuckle

9

K

2 Steering knuckle (king) pins - inspect

9

K

11 REAR AXLES

1 Drive axle - check oil level, add if necessary

35

2 Tag axle lever pivot - grease one fitting on each pivot

15

K

3 Drive axle -

change oil, clean breathers

35

E

4 Drive axle -

change oil, clean breathers (with full synthetic oil)

35

F

12 BRAKE & AIR

1 Brakes – check caliper running clearance

at brake pad replacements

2 Brake – check pad wear indicator. Visually check condition of the slack adjuster cap

& guide pin covers

3 Air tanks - drain water from all tanks

7

4 Haldex Consep Condenser/Separator - inspect

5 Brakes – check caliper movement along guide pins, check sealing elements (boots).

Check proper functioning of the adjuster

6 Accessories air filter - change filter element

3

7 Air dryer - change cartridge

36

13 WHEELS, HUBS & TIRES

1 Hub bearing - inspect

14 STEERING

1 Steering tie rod ends - clean & grease one fitting at each end

40

K

2 Drag link ends - clean & grease one fitting at each end

4

K

3 Steering damper cylinder - grease one fitting at rod end

39

K

4 Drag link end & tie rod end ball joints - inspect for corrosion

5 Power steering reservoir filter cartridge - replace

29

6 Power steering fluid - replace

29

B

16 SUSPENSION

1 Air bellows - inspect

18 BODY

1

Front bumper, front service compartment & evaporator compartment door latch,

grease fitting

K

22 HEATING & AIR CONDITIONING

1 Passengers HVAC unit return air filters (2) - clean

10

2 Evaporator compartment door fresh air intake filter - clean

3 Parcel rack fans air filter – clean

4 Driver HVAC unit return & fresh air filters – clean

10

5 A/C compressor - check oil level, add if necessary

25

D

6 A/C receiver tank - check refrigerant level, add if necessary

37

7 Refrigerant moisture indicator - check, replace filter dryer unit according to moisture

indicator

38

8 Passengers & Driver HVAC units - clean heater core with low pressure water hose

9 Passengers HVAC unit - clean evaporator core with low pressure water hose

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...