Section 03: FUEL SYSTEM

PA1593

11

5.2 AIR CLEANER SERVICING

Stop the engine, open the R.H. side engine

compartment door, and loosen the wing nut

retaining the air cleaner element to the air

cleaner. Remove the element by pulling on the

handle in the center of the air cleaner element.

Install cleaner element as follows:

1. Inspect the gasket-sealing surface inside the

air cleaner. It must be smooth, flat and clean;

2. Install the air cleaner element;

3. Make sure that the element seals securely;

4. Inspect element cover gasket and replace if

necessary.

Whenever it becomes necessary to remove the

air cleaner assembly (dry type) for maintenance

or other repair in this area, great care should be

taken when installing air cleaner assembly.

The pre-filter should be installed snugly in the air

duct and clamped tightly to the air cleaner inlet

to prevent any dust infiltration into the air

cleaner.

5.3 GENERAL RECOMMENDATIONS

The following maintenance procedures will

ensure efficient air cleaner operation:

1. Keep the air cleaner housing tight on the air

intake pipe;

2. Make sure the correct filters are used for

replacement;

3. Keep the air cleaner properly assembled so

the joints are air-tight;

4. Immediately repair any damage to the air

cleaner or related parts;

5. Inspect, clean or replace the air cleaner or

elements as operating conditions warrant.

Whenever an element has been removed

from the air cleaner housing the inside

surface of the housing must be cleaned with

a soft clean cloth;

6. Periodically inspect the entire system. Dust-

laden air can pass through an almost

invisible crack or opening which may

eventually cause damage to an engine;

7. Never operate the engine without an element

in the air cleaner assembly;

CAUTION

Do not ignore the Warning given by the air

restriction indicator. This could result in

serious engine damage.

8. Store new elements in a closed area free

from dust and possible damage.

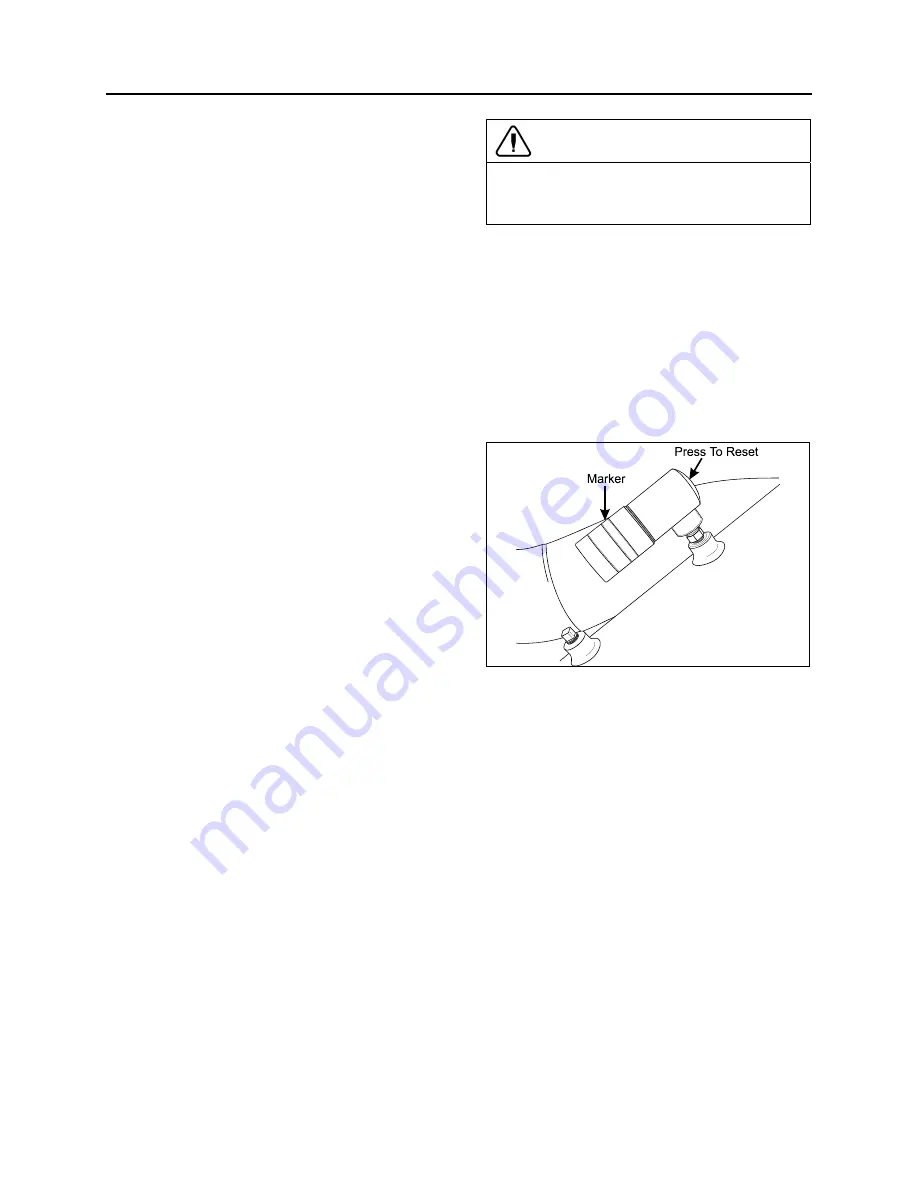

5.4 AIR CLEANER RESTRICTION INDICATOR

A resettable restriction indicator may be installed

on the engine air-intake duct, clearly visible from

the rear engine compartment. The indicator

monitors the vacuum level between the air filter

and the engine. A red marker is displayed when

the air filter is clogged and must be replaced.

Reset by pressing on the indicator's extremity.

FIGURE 10: RESTRICTION INDICATOR

01052

6. FUEL

PEDAL

The EFPA (Electronic Foot Pedal Assembly)

connects the accelerator pedal to a

potentiometer (a device that sends an electrical

signal to the ECM, which varies in voltage,

depending on how far down the pedal is

depressed). The EFPA is installed in the space

normally occupied by a mechanical foot pedal. It

has maximum and minimum stops that are built

into the unit during manufacturing.

6.1 FUEL PEDAL ADJUSTMENT

The EFPA contains a throttle position sensor

that varies the electrical signal sent to the ECM.

The sensor must be adjusted whenever an

EFPA is serviced. In addition, the sensor should

be adjusted any time codes 21 and 22 are

flashed.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...