Section 04: EXHAUST AND AFTERTREATMENT SYSTEM

PA1593

10

5.1 DIESEL EXHAUST FLUID

When handling DEF solution, it is important that

electrical connectors to be connected or well

encapsulated, otherwise there is a risk that the

DEF will cause oxidation that cannot be

removed. Water or compressed air will not help,

since DEF quickly oxidizes certain metals. If a

disconnected connector comes into contact with

the DEF solution, it must be replaced

immediately to prevent the DEF solution from

creeping further into the copper wiring, which

takes place at a speed of about 2.4 in (60 mm)

per hour.

CAUTION

Diesel Exhaust Fluid (DEF) is a nontoxic

aqueous solution of urea (32.5%) and ultra-

pure water (67.5%). Urea is a compound of

nitrogen that turns to ammonia when heated.

The fluid is non-flammable, and is not

dangerous when handled as recommended.

However, it is highly corrosive to certain

metals, especially copper and brass.

When detaching hoses and components, do

not spill DEF on disconnected or unsealed

connectors. If DEF is spilled on a

disconnected or unsealed connector, the

connector must be removed immediately and

replaced.

Things to know about spilt diesel exhaust fluid

(DEF):

If urea solution comes into contact with the

skin, rinse with plenty of water and remove

contaminated clothing.

If urea solution comes into contact with the

eyes rinse for several minutes and call for

medical help if necessary.

If inhaled breathe fresh air and call for

medical help if necessary.

Do not allow the DEF solution to come into

contact with other chemicals.

The DEF solution is not flammable. If the

DEF solution is exposed to high

temperatures, it breaks down into ammonia

and carbon dioxide.

The DEF solution is highly corrosive to

certain metals, including copper and

aluminum.

If the DEF solution is spilled onto the vehicle,

wipe off the excess and rinse with water.

Spilled DEF solution can form concentrated

white crystals on the vehicle. Rinse off these

crystals with water.

WARNING

DEF spilt onto hot components will quickly

vaporize. Turn your face away!

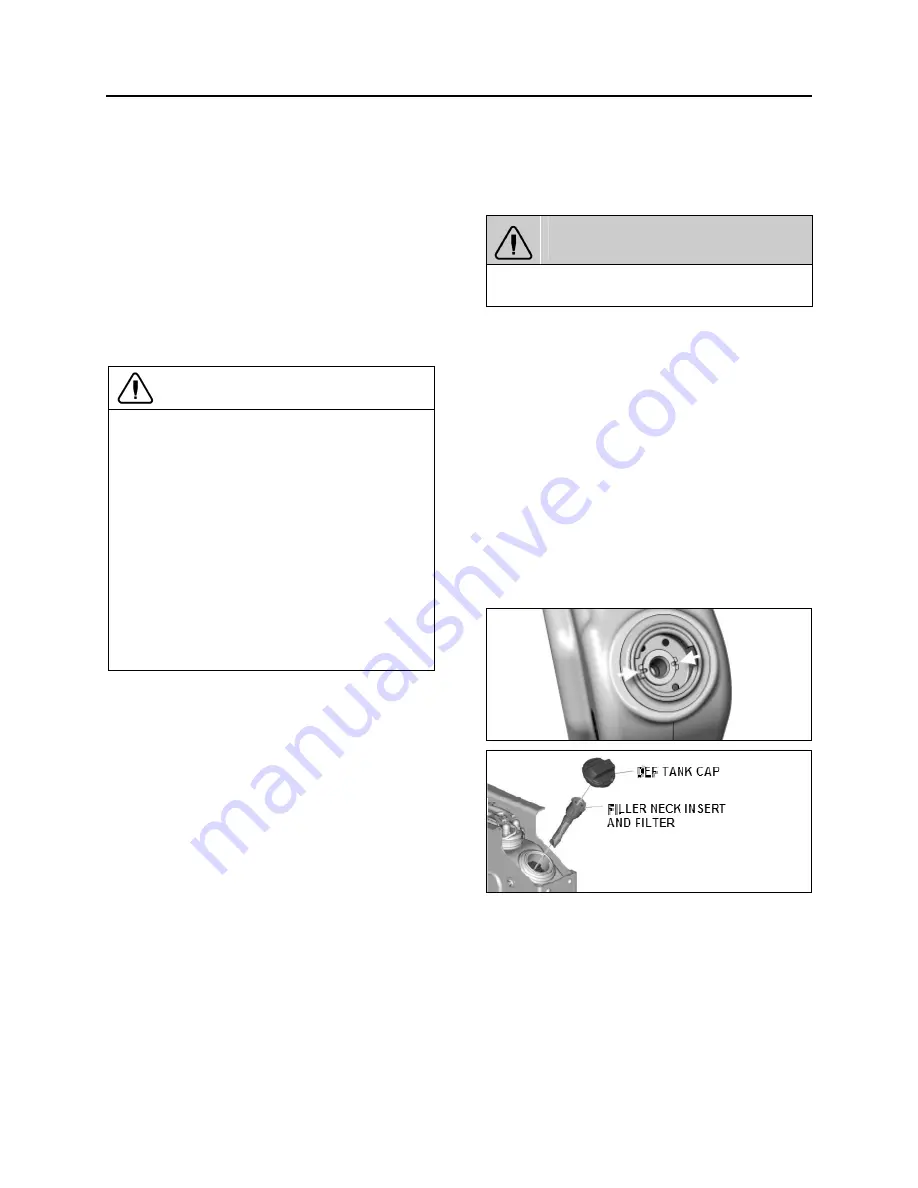

5.2 DEF TANK CLEANING

Removing the DEF tank for cleaning is not

necessary.

1. Put a suitable container under the DEF tank.

2. Remove the DEF tank drain plug through the

DEF tank support pan access hole.

3. Let all of the DEF drain from the tank.

Discard the used DEF according to local

regulations.

4. Remove the DEF tank filler neck insert. To

do so, release the retaining tab and remove

filler neck insert. Replace old seal if

damaged.

5. Flush the tank with hot water. Let all of the

water drain from the tank.

6. Clean the filler neck insert screen with hot

water.

7. Reinstall the filler neck insert until the

retaining tabs snap into filler neck. Reinstall

DEF tank drain plug.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...