Section 04: EXHAUST AND AFTERTREATMENT SYSTEM

PA1593

12

CAUTION

It must be checked if there are cracks around

the area of the filter cover. No cracks in the

material are allowed. If there are cracks in the

housing, the entire Supply Module must be

replaced! If there are cracks in the filter cover,

the filter cover must be replaced.

MAINTENANCE

Replace pump assembly filter element every

150,000 miles or every three years, whichever

comes first.

6.

AFTERTREATMENT FUEL INJECTOR

Proper functioning of the aftertreatment fuel

injector a.k.a. aftertreatment hydrocarbon

injector (AHI) is required in order to obtain

efficient regeneration process of the DPF.

Clogged aftertreatment fuel injector will result in

clogged DPF.

In addition to the activation of the CHECK

telltale, emission of diagnostic troubleshooting

codes (DTC) by the engine ECM (MID128) will

indicate malfunction of the aftertreatment system

and/or aftertreatment fuel injector. DTC may be

accessed through the Driver Information

Display. Select DIAGNOSTICS menu then

FAULT DIAGNOSTICS and ENGINE ECU

submenus.

Check status of the aftertreatment system

through the Driver Information Display. Select

AFTERTREATMENT menu then ATS STATUS.

Then check the DPF soot level with SOOT

LEVEL GAUGE.

6.1 REPLACEMENT

1. Remove fastener and p-clamp securing the

line to the mounting bracket on the diffuser

pipe.

WARNING

Fuel leaked or spilled onto hot surfaces or

electrical components can cause a fire and

result in component damage and serious

personal injury.

2. Disconnect the line from the aftertreatment

hydrocarbon injector fitting. Collect any

residual fuel that might be in the line in a

suitable container.

CAUTION

Do not kink the line. Kinking the line may

result in leakage.

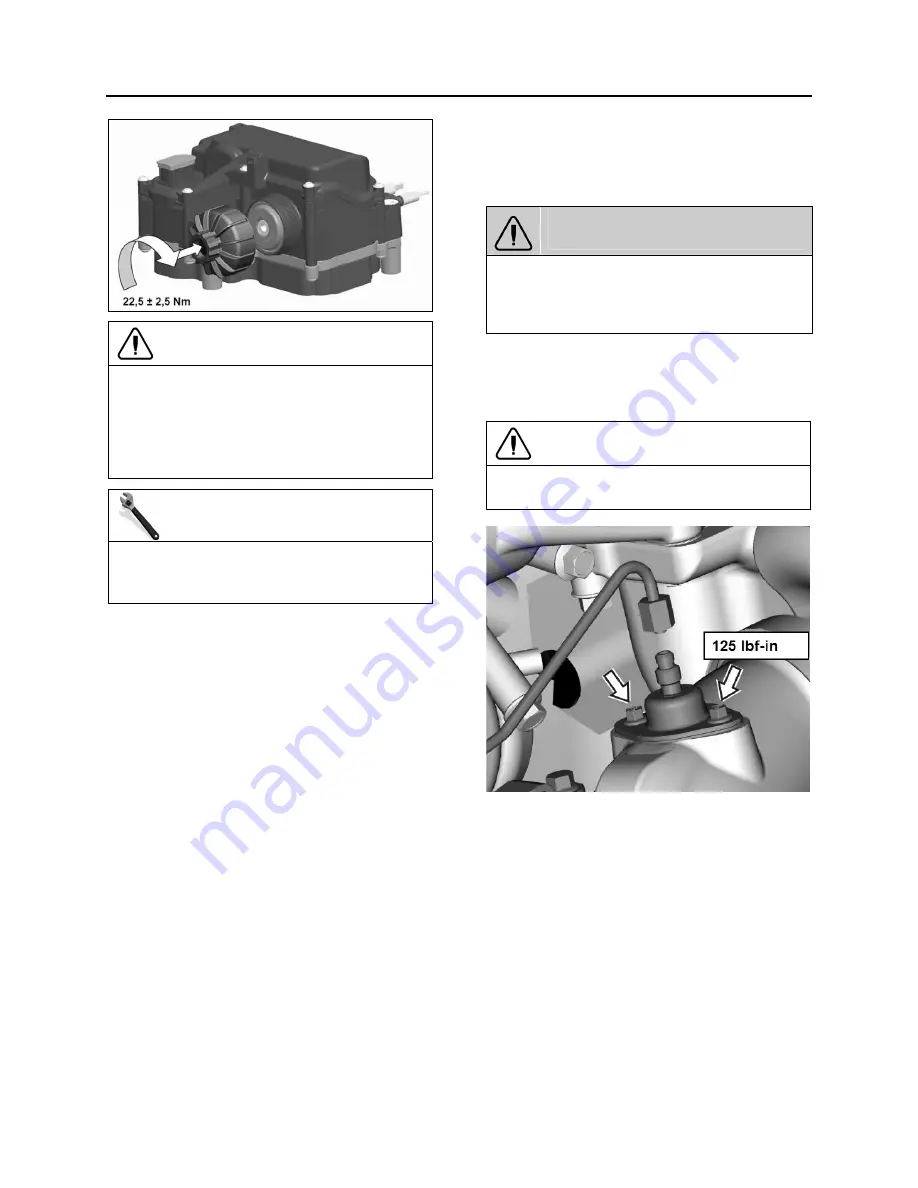

FIGURE 9: AFTERTREATMENT FUEL INJECTOR

3. Remove the aftertreatment hydrocarbon

injector mounting fasteners. Remove the

aftertreatment hydrocarbon injector from the

diffuser pipe (which attaches to the

turbocharger outlet).

4. Clean the sealing surface on the diffuser pipe

before mounting the aftertreatment

hydrocarbon injector.

5. Install the aftertreatment hydrocarbon injector

onto the diffuser pipe (which attaches to the

turbocharger outlet). Tighten the fasteners to

125 lbf-in

.

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...