Section 05: COOLING SYSTEM

6

X3-45 Commuter PA1593 DOB 2400-2489

Section 05 Updated Sept.2016

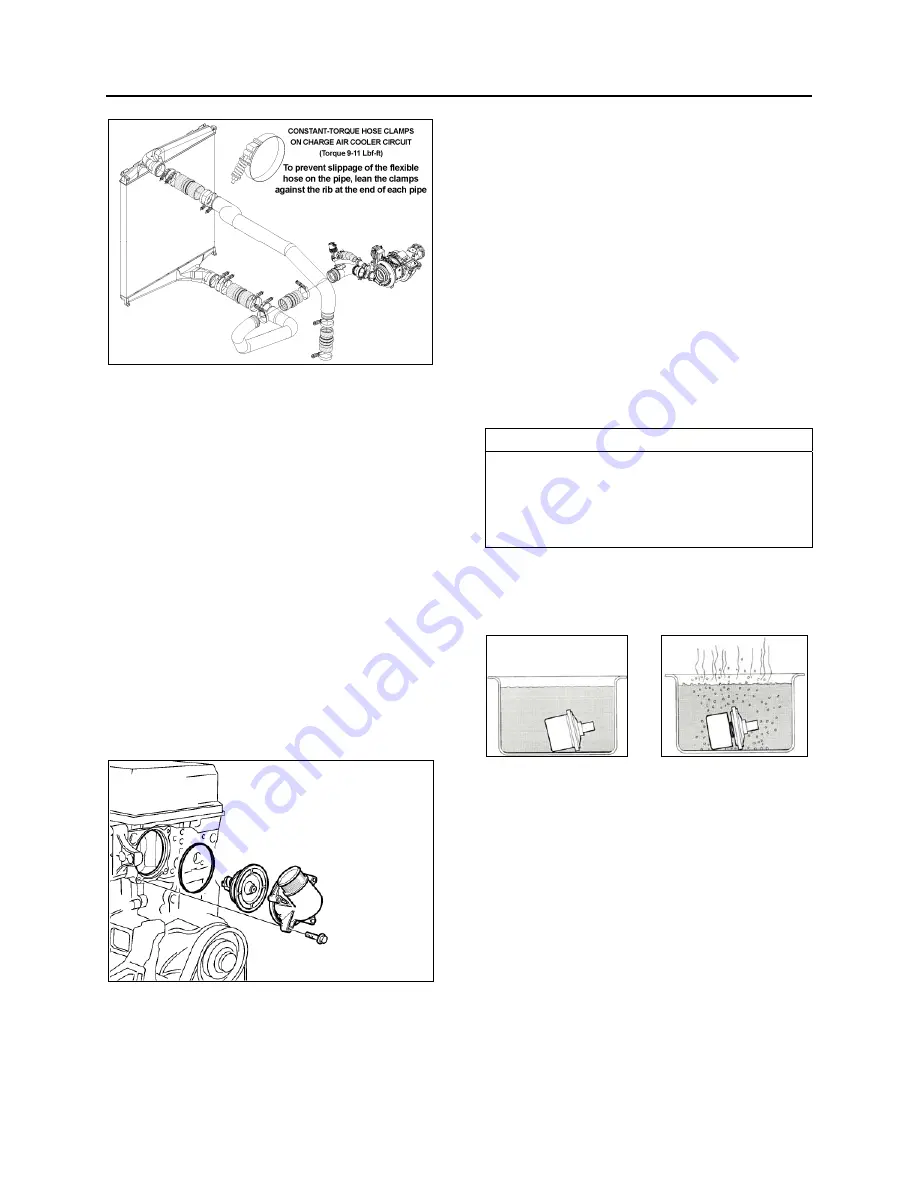

FIGURE 5: CHARGE AIR COOLER HOSE CLAMPS

3.2.1 Maintenance

Since the constant-torque clamp automatically

adjusts to keep a consistent sealing pressure,

there is no need to retorque hose clamps on a

regular basis. During vehicle operation and

shutdown, the screw tip will adjust according to

the temperature and pressure changes.

Checking for proper torque should be done

at room temperature.

4. THERMOSTAT OPERATION

4.1 THERMOSTAT REPLACEMENT

1. Drain the cooling system.

2. Remove the bolts, the thermostat housing

and the thermostat. Carefully clean the

thermostat seat and all cylinder head-to-

thermostat housing mating surfaces.

FIGURE 6: VOLVO D13 THERMOSTAT HOUSING

3. Install the new thermostat. Make sure that

the rubber seal remains properly seated.

4. Position the thermostat housing to the

cylinder head, install the bolts and torque-

tighten to 24 ± 4 Nm (18 ±3 ft-lb).

5. Install the rubber radiator hose to the

thermostat housing. Position the clamp and

tighten to secure.

6. Fill the system with the recommended

coolant.

7. Start the engine, check for leaks and proper

operation. After shutdown, replenish fluids as

necessary.

4.2 CHECKING THERMOSTAT

A function check must be carried out before

installing a new thermostat.

NOTE

Check to be sure that the thermostat closes

fully. This can be done by holding it up to the

light to check that there is no visible gap at the

opening point. If the thermostat does not close

properly, replace it.

1. Warm up water in a receptacle to 75°C

(167°F) and immerse the thermostat in the

water. Use a piece of wire attached to the

thermostat.

2. After at least 30 seconds, check that the

thermostat is still closed.

3. Now warm the water to 100°C (212°F). After

at least 30 seconds at the boiling point,

check that the thermostat has opened at

least 7mm (9/32”). If the thermostat has not

opened, it must be replaced. A good

thermostat starts to close at 95°C (203°F)

and is fully closed at approximately 85°C

(185°F).

5. COOLANT

5.1 COOLANT LEVEL VERIFICATION

If coolant level has reached the bottom of the

sight glass, add coolant. Coolant level is correct

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...