Section 05: COOLING SYSTEM

Section 05 Updated Sept.2016

X3-45 Commuter PA1593 DOB 2400-2489

15

1. Unwrap the drive belt from around the pulley

(see paragraph MOUNTING THE DRIVE

BELT).

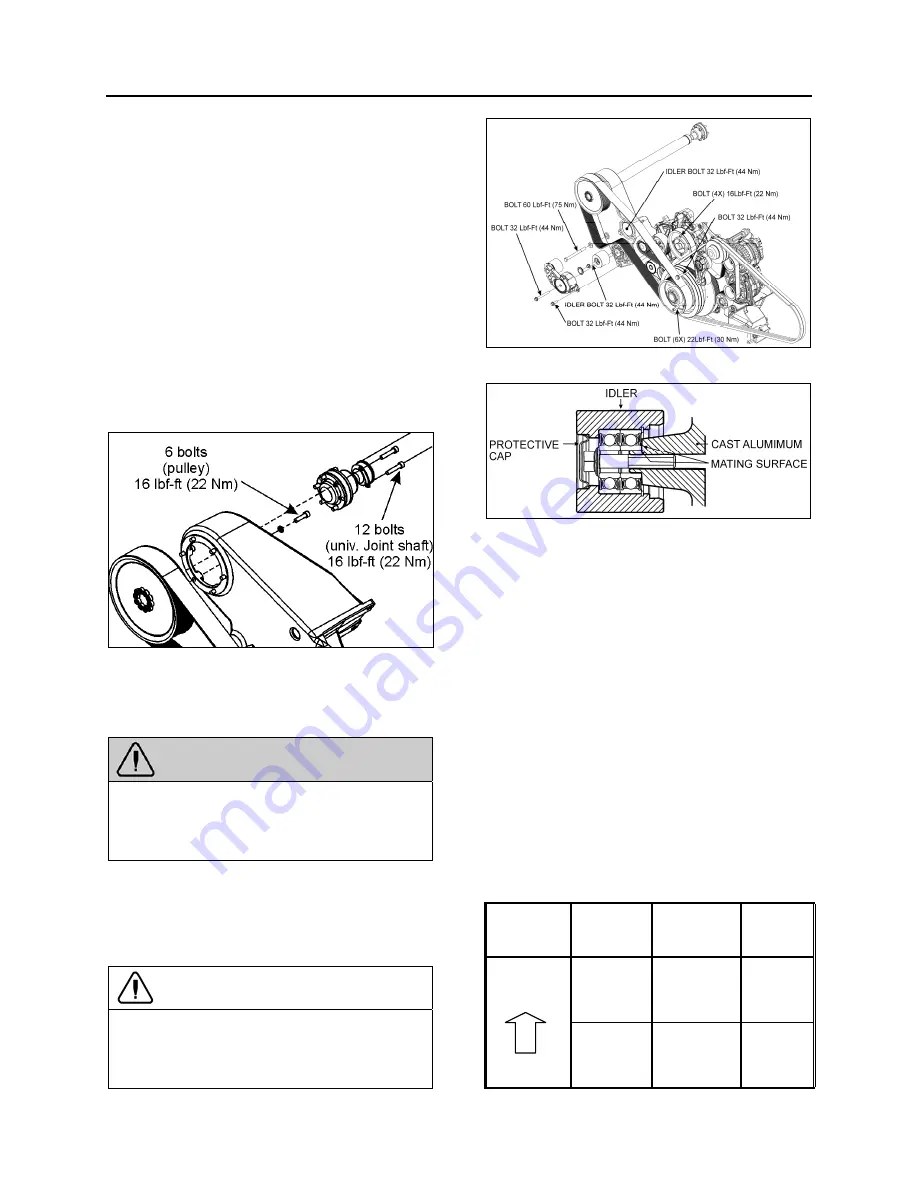

2. Dismount the drive pulley. Gain access to the

6 mounting bolts from behind the pulley,

through the opening in the cast aluminum

support (Fig. 23).

3. Unscrew and remove the universal joint shaft

mounting bolts (6) at the right angle gearbox.

4. Slowly, move the shaft toward the rear of the

vehicle.

5. Finally, dismount the universal joint shaft

from the drive pulley (6 bolts).

Installation of the universal joint shaft is the

same as removal, but in reverse order.

FIGURE 23: TIGHTENING SPECIFICATION

05123A

12.2 IDLER REPLACEMENT

If an idler is defective, replace as follow:

WARNING

Turn the ignition switch to the OFF position

and set starter selector switch to the OFF

position to prevent accidental starting of the

engine.

1. Remove the protective cap (replace with a

new one).

2. Unscrew the idler mounting bolt.

3. Replace idler with a new one.

CAUTION

When installing the idler, make sure it rests

perfectly against the bearing surface on the

cast aluminum support. If not, the drive belt

may slip of the idler. See following figure.

FIGURE 24: TIGHTENING SPECIFICATION (VOLVO D13

ENGINE)

FIGURE 25: IDLER MOUNTED ON THE CAST ALUMINUM

SUPPORT

4. Bolt the new idler on the cast aluminum

support. Tighten to 32 lbf-ft (44 Nm).

5. Place a new protective cap.

13. VARIABLE SPEED COOLING FAN

The cooling fan clutch has two thermostatically

controlled speeds, plus a neutral (clutch

disengaged). The engine control module

controls the speed by comparing data from

engine coolant temperature, charge air

temperature, Allison transmission oil

temperature (if applicable) and small A/C High

side pressure to a set of calibration data. The

fan drive clutch is electromagnetic; the engine

control module sends an electric current to

regulate speed by activating one magnetic coil

for the first speed and two magnetic coils for the

second speed.

The settings are:

Engine

coolant

temp.

Air intake

temp.

Allison

trans. oil

temp.

temperature

rising

208°F: fan

engages in

HIGH

SPEED

194°F: fan

engages in

HIGH

SPEED

230°F: fan

engages

in HIGH

SPEED

203°F: fan

engages in

LOW

SPEED

176°F: fan

engages in

LOW SPEED

216°F: fan

engages

in LOW

SPEED

Summary of Contents for X3-45 2016

Page 4: ......

Page 16: ...Section 00 GENERAL INFORMATION PA1593 12 FIGURE 12 METRIC US STANDARD CONVERSION TABLE 00005...

Page 17: ...Section 00 GENERAL INFORMATION 13 PA1593 FIGURE 13 CONVERSION CHART 00006...

Page 18: ......

Page 26: ......

Page 58: ......

Page 72: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 14 7 TORQUE SPECIFICATIONS...

Page 73: ...SECTION 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 15...

Page 74: ...Section 04 EXHAUST AND AFTERTREATMENT SYSTEM PA1593 16...

Page 76: ......

Page 96: ......

Page 134: ......

Page 176: ...SECTION 06B ELECTRICAL 38 overcurrent working Circuit 306 shorted to ground...

Page 180: ......

Page 202: ......

Page 205: ...Section 09 PROPELLER SHAFT PA1593 3 FIGURE 1 PROPELLER SHAFT ASSEMBLY 09002...

Page 256: ......

Page 268: ......

Page 295: ...SECTION 16 SUSPENSION PA1593 9 2 5 TORQUE SPECIFICATIONS...

Page 296: ...Section 16 SUSPENSION PA1593 10...

Page 297: ...Section 16 SUSPENSION PA1593 11...

Page 314: ......

Page 380: ......

Page 388: ......

Page 413: ...Section 22 HEATING AND AIR CONDITIONING PA1593 15 FIGURE 18 REFRIGERANT CIRCUIT CENTRAL SYSTEM...

Page 433: ...Section 22 HEATING AND AIR CONDITIONING PA1593 35 FIGURE 36 CENTRAL HEATING SYSTEM COMPONENTS...