IN-STATION LIGHTING

The in-station lighting system circuit is linked

with the optional battery charger: When the

charger is connected to an external power

source, the in-station lighting circuit can be

energized without depleting the batteries.

The receptacle used for the battery charger is

located on the main power compartment door.

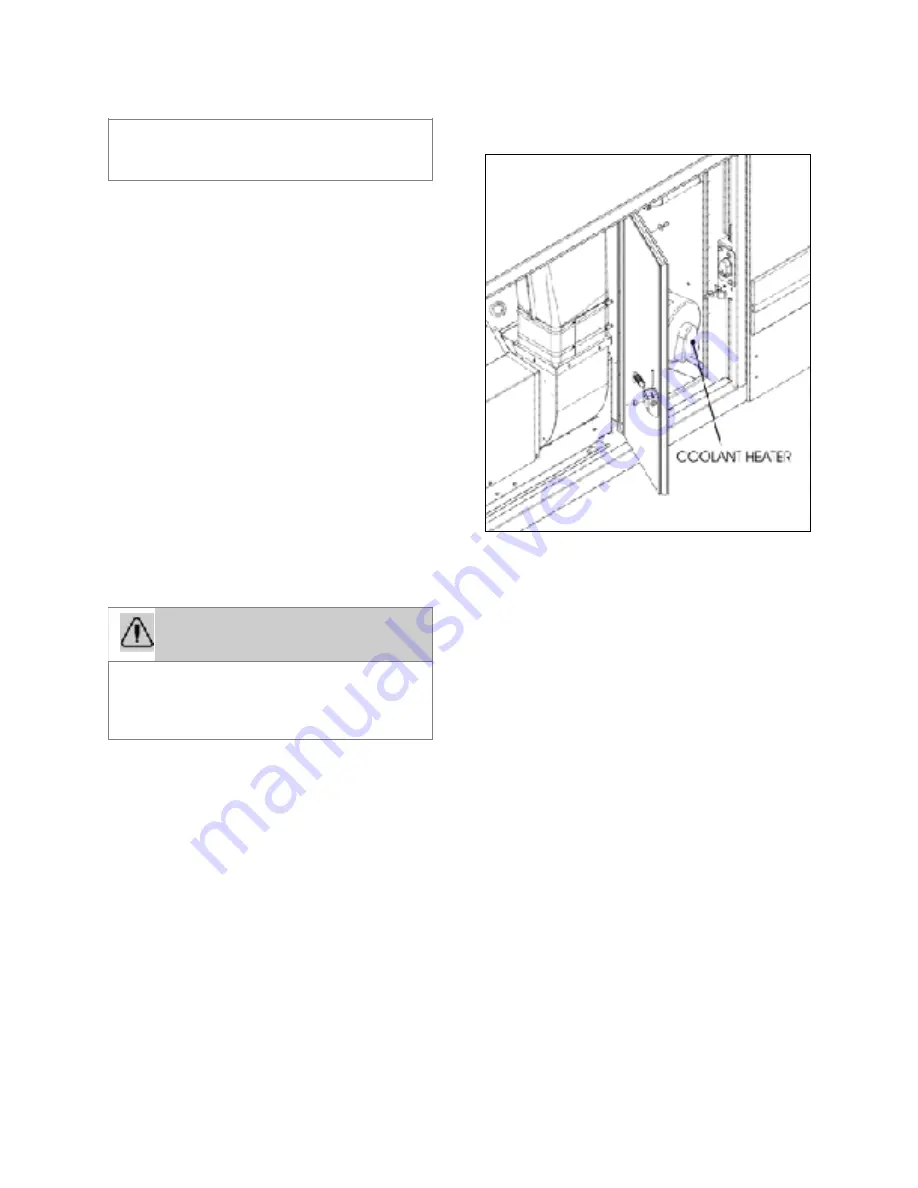

ENGINE COOLANT HEATER

This optional auxiliary heating system is used for

preheating and retaining the heat of water-

cooled engines. It can be used before startup to

ease starting and to provide rapid operation of

the interior heating system. It can also be used

with the engine running to maintain coolant heat

and interior temperature.

The heater operates independently of the

engine. It is connected to the cooling system,

heating circuits and to the vehicle’s fuel and

electrical system.

SWITCHING THE HEATER ON

The timer light illuminates when the heater is

switched

ON

. Air is forced in to flush out the

combustion chamber of residual gases and the

water circulation pump begins operating. The

fuel metering pump delivers fuel in precise

amounts to the combustion chamber, where fuel

and combustion air form a combustible mixture

which is ignited by the ignition unit.

Once the flame sensor has signaled to the

control unit that combustion has taken place, the

ignition unit is switched

OFF.

The dashboard

telltale light will illuminate to indicate when the

burner is

ON.

Hot combustion gases are diverted at the end of

the flame pipe and are then forced through the

indirect heating surfaces of the heat exchanger.

The heat exchanger transfers the heat to the

Other Features 5-27

coolant water passing through the heat

exchanger.

!

LOCATION OF PREHEATER

18607

The heater is thermostatically controlled and

operates intermittently (i.e., the switched-on time

of the burner varies depending on the heat

requirement). The water temperature is

controlled by the built-in water thermostat.

The water circulation pump remains in operation

as long as the heater is operating, even during

the regulated intervals and during the delayed

cut-out of the heater. The pump can also be

operated independently of the heater by means

of an appropriate circuit. The heater can be

switched

ON

at any time (i.e., during the delayed

cut-out period). Ignition takes place after the

delayed cut-out time expires.

SWITCHING THE HEATER OFF

The fuel supply is interrupted when the heater is

switched

OFF

. This causes the flame to go out

and a delayed cut-out of 2.5 minutes begins. The

circulating combustion air flushes the remaining

combustion gases out of the chamber and cools

off the heated parts on the exhaust side of the

heat exchanger. The water circulation pump

continues to transfer the latent heat present in

the heat exchanger, thus preventing hot spots.

Once the delayed cut-out time expires, both the

combustion air blower and the water circulation

pump switch

OFF

automatically. A cut-out will

automatically take place in case of heater failure.

In order to prevent damage to the

suspension, always raise the tag axle before

lifting the coach.

WARNING

The coolant heating system uses the same

fuel as the engine. Do not operate in a

closed building or while refueling. Operate

only in a well ventilated area.

!

Summary of Contents for X3-45 COACH

Page 1: ...OPERATOR S MANUAL X3 45 COACH ...

Page 2: ......

Page 3: ...COACH MANUFACTURER OPERATOR S MANUAL X3 45 COACH PA1609 December 2015 ...

Page 8: ......

Page 13: ......

Page 18: ... WARNING Unless otherwise stated do not run the engine when the engine compartment is open ...

Page 25: ...either open or shut A key is provided for unlocking the door if the option was chosen ...

Page 153: ... ...

Page 164: ......

Page 176: ......

Page 189: ...INTERIOR UNLATCH AIR VALVE 12164 ...

Page 190: ...7 4 Safety Features and Equipment UNLATCH AIR VALVE LOCATION 12209 ...

Page 192: ...an audible alarm will sound 2 The operator shall bring the vehicle to a safe stop ...

Page 213: ......

Page 220: ......

Page 239: ...9 2 Technical Information VEHICLE IDENTIFICATION NUMBER VIN 13 COACH FINAL RECORD 13 ...

Page 240: ...Technical Information 9 3 X3 45 OVERALL DIMENSIONS SIDE ELEVATION 18673_1 ...

Page 241: ...9 4 Technical Information X3 45 OVERALL DIMENSIONS TOP FRONT AND REAR VIEWS 18674_1 ...

Page 256: ......

Page 258: ......

Page 262: ......

Page 264: ...4 Try disconnecting the CECM ...

Page 266: ......

Page 268: ......

Page 292: ......