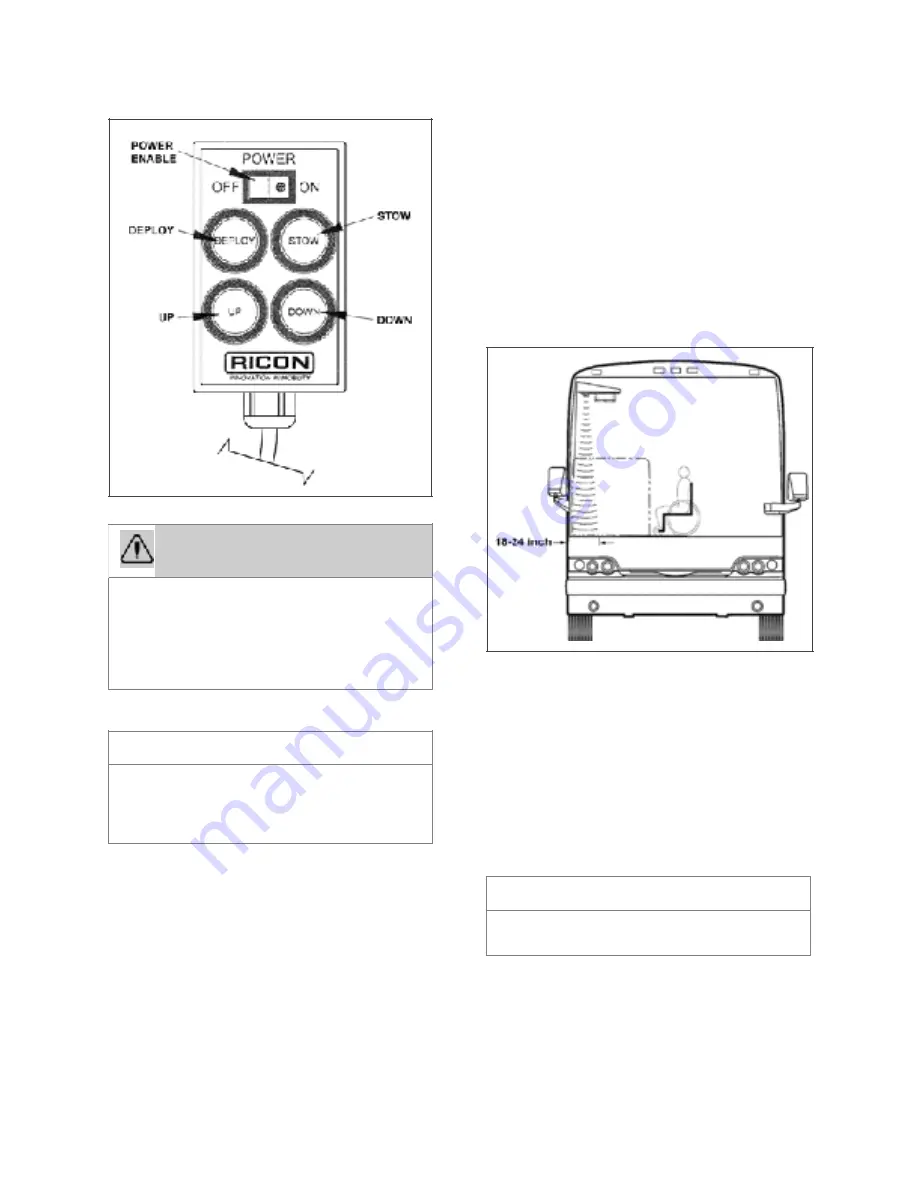

CONTROL PENDANT

23364

To stow the platform, detach the restraint belt

and fold the left handrail, then fold the right

handrail (lift the slam lock handles to fold

handrails). Re-fasten restraint belt. Press down

and hold the STOW button until the lift is fully

stowed.

THRESHOLD WARNING SYSTEM (TWS)

ADJUSTMENT

There are three verifications to perform; 1)

Adjust Aiming of Acoustic Sensor Beam, 2) Test

Aim of Acoustic Sensor Beam, and 3) Adjust

Acoustic Sensor Timing.

Adjustment of the sensor timing is done at the

factory and should not need to be repeated in

Other Features 5-31

the field. Readjustment should only be

considered if the sensor aiming could not be

adjusted to ignore both the wheelchair in the

aisle and the platform during its normal

movement.

Adjust Aiming of Acoustic Sensor Beam

1. Place wheelchair with passenger in center

aisle of coach, pointed at doorway where

Threshold Warning System (TWS) is

installed. The TWS should not detect a

wheelchair and passenger when they are

located this far from doorway.

TWS AREA

23371

2. Turn power to lift on (LED on TWS module

will light steady) and indicator light on the

control device illuminates. If wheelchair and

passenger are detected by acoustic sensors

the LED will flash, the buzzer will sound and

the module red light will flash. If this occurs it

is necessary to adjust aiming of sensors.

3. Turn sensor angle adjustment screw

clockwise to move direction of beam away

from center aisle and towards doorway. Stop

adjustment when LED ceases to flash.

4. Move centerline of small wheels of

wheelchair (with passenger) to within 24

inches of doorway and repeat aiming

procedure in previous step.

!

WARNING

Use extreme care when rolling on or off the

platform and lock the wheelchair brakes

while stationary on the platform. Make sure

the wheelchair fits safely on the platform.

Keep arms and legs away from moving

parts.

!

NOTE

The indicator light on the control device

illuminates when power is supplied (when

the lift electrical circuit is activated by the

switch on the dashboard).

!

NOTE

Only in rare instances will adjustment be

needed in the counterclockwise direction.

Summary of Contents for X3-45 COACH

Page 1: ...OPERATOR S MANUAL X3 45 COACH ...

Page 2: ......

Page 3: ...COACH MANUFACTURER OPERATOR S MANUAL X3 45 COACH PA1609 December 2015 ...

Page 8: ......

Page 13: ......

Page 18: ... WARNING Unless otherwise stated do not run the engine when the engine compartment is open ...

Page 25: ...either open or shut A key is provided for unlocking the door if the option was chosen ...

Page 153: ... ...

Page 164: ......

Page 176: ......

Page 189: ...INTERIOR UNLATCH AIR VALVE 12164 ...

Page 190: ...7 4 Safety Features and Equipment UNLATCH AIR VALVE LOCATION 12209 ...

Page 192: ...an audible alarm will sound 2 The operator shall bring the vehicle to a safe stop ...

Page 213: ......

Page 220: ......

Page 239: ...9 2 Technical Information VEHICLE IDENTIFICATION NUMBER VIN 13 COACH FINAL RECORD 13 ...

Page 240: ...Technical Information 9 3 X3 45 OVERALL DIMENSIONS SIDE ELEVATION 18673_1 ...

Page 241: ...9 4 Technical Information X3 45 OVERALL DIMENSIONS TOP FRONT AND REAR VIEWS 18674_1 ...

Page 256: ......

Page 258: ......

Page 262: ......

Page 264: ...4 Try disconnecting the CECM ...

Page 266: ......

Page 268: ......

Page 292: ......