5-36 OTHER FEATURES

PA1633 X3-45 Commuter Operator’s Manual

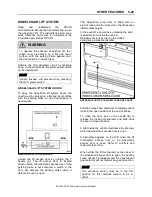

CLOCKWISE ROTATION CLOSES ROLLSTOP

23275

3. Verify that rollstop is up (closed). Pull

rollstop control knob out and rotate fully

clockwise, if it isn’t up.

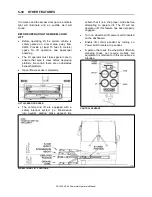

4. Insert handle extension into manual backup

pump handle socket and pump to raise the

platform to the vehicle floor level.

CAUTION

During manual rising of the lift, do not raise

the platform more than 1-1/2 inches above the

vehicle floor level. Any excessive travel will

make it difficult to enter the platform and/or

damage the lift bridge plate actuator. The

outer edge of the bridge plate must rest

squarely on the vehicle floor.

WHEELCHAIR LIFT MANUAL HYDRAULIC PUMP

23373

5. The lift passenger and attendant must follow

the instructions to ENTER or EXIT the

vehicle, as previously described.

To manually lower the platform

1. Verify that rollstop is up (closed). Pull

rollstop control knob out and rotate

clockwise, if it isn’t up.

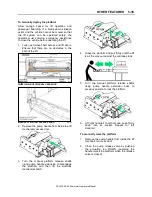

2. Slowly pull the pump release valve actuating

rod UP until the platform begins to lower

(opening the release valve lowers platform).

3. Allow the platform to reach ground level.

4. Push the pump release valve actuating rod

back DOWN until lightly-snug.

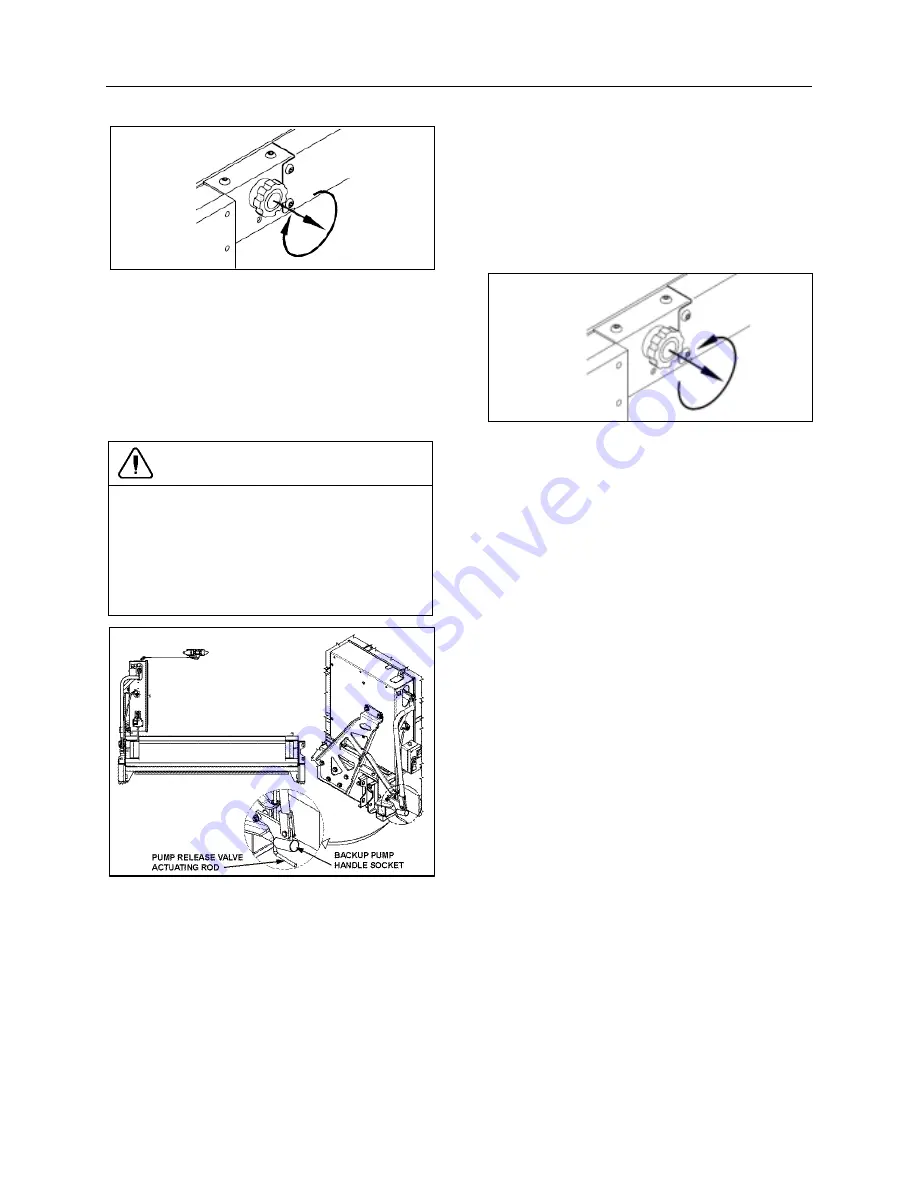

5. Using the rollstop manual control knob,

OPEN the rollstop. Pull rollstop control knob

out and rotate fully counterclockwise.

Rollstop must lie flat on ground.

COUNTERCLOCKWISE ROTATION OPENS ROLLSTOP

6. The attendant and lift passenger should

follow the instructions to ENTER or EXIT the

vehicle, as described previously.

To manually stow the platform

1. Detach the restraint belt, lift each handrail

up to unlock and fold handrails. Re-fasten

restraint belt.

2. Raise or lower the platform to the

deploy/stow position; the platform frame

must be parallel to the side of the lift

enclosure. If the exact position cannot be

obtained, slightly low is preferred to slightly

high.

3. Using the rollstop manual control knob and

one hand one the rollstop, close the rollstop

until it latches.

4. Turn the manual platform release shafts

using pump handle extension to disengage

the platform.

5. Use one person on each side of the lift to

prevent mechanical binding.

6. With fingers up and palms forward, push the

platform forcefully to start the lift moving

inward. As the lift begins to move inward,

maintain a constant pushing motion until the

lift comes to rest completely inside the lift

enclosure.

7. Push firmly and make sure that the platform

manual release shafts have turned to lock

the platform.

Summary of Contents for X3-45 COMMUTER 2018

Page 1: ...OPERATOR S MANUAL X3 45 COMMUTER COACH...

Page 2: ......

Page 3: ...COACH MANUFACTURER X3 45 COMMUTER OPERATING MANUAL March 2018...

Page 4: ...PA1633 MARCH 2018 Featuring REVISION DESCRIPTION DATE FIRST RELEASE 03 2018...

Page 8: ......

Page 12: ......

Page 70: ...4 36 CONTROLS AND INSTRUMENTS PA1633 X3 45 Commuter Operator s Manual...

Page 108: ...5 38 OTHER FEATURES PA1633 X3 45 Commuter Operator s Manual...

Page 116: ...6 8 STARTING AND STOPPING PROCEDURES PA1633 X3 45 Commuter Operator s Manual...

Page 120: ...7 4 SAFETY FEATURES AND EQUIPMENT PA1633 X3 45 Commuter Operator s Manual KIDDE IMAGES...

Page 128: ...7 12 SAFETY FEATURES AND EQUIPMENT PA1633 X3 45 Commuter Operator s Manual...

Page 148: ...8 20 CARE AND MAINTENANCE PA1633 X3 45 Commuter Operator s Manual...

Page 150: ...9 2 TECHNICAL INFORMATION PA1633 X3 45 Commuter Operator s Manual OVERALL DIMENSIONS...

Page 158: ...9 10 TECHNICAL INFORMATION PA1633 X3 45 Commuter Operator s Manual...

Page 160: ......

Page 164: ......